How Does Well Control Work?

The most hazardous and catastrophic possible disasters in the field of oil drilling are without a doubt blowouts. They can result in severe harm, even fatalities, as well as large-scale, crippling production shutdowns and a negative impact on subsequent output from the well. Blowouts can seriously harm the environment. When working with high-pressure drilling activities, it’s essential that you have a well-control system in place. By taking precautions and adhering to control procedures, you can lower your risk of a blowout.

The term “blowout prevention” covers a wide range of activities, from preventative measures taken on drilling rigs to stop “kicks” — the unanticipated and unwanted flow of formation fluids into a well — from occurring, to the use of sophisticated Blowout Preventers (or BOPs) designed to seal off a well in the event of an impending blowout.

Preparation is the first step in preventing blowouts.

Drilling operators must balance the enormous upward pressure of the formation fluids flowing up the well with “drilling mud,” also known as drilling fluid, a viscous liquid that resembles mud and comes in a variety of densities, in order to prevent kicks. Bottomhole pressure is the term used to describe the drilling fluid’s downward pressure. It is a laborious but crucial work for drilling fluid engineers to watch and be cautious to make sure that the pressures attain balance.

Symptoms of a Kick in the Wellbore

Every oil field worker is aware of how crucial it is to maintain a constant fluid balance in the wellbore. An indication that something is seriously wrong and a kick is happening is when the amount of drilling fluid unexpectedly and significantly increases. Knowing the symptoms of a kick in the wellbore will give you enough time to take appropriate action and avoid a blowout.

How to Avoid Well Blowouts

Well blowouts can be avoided in a number of ways before they happen. Maintain BOPs in good condition by cleaning out the mud and removing metal fragments with a downhole magnet to lower the possibility of a leak or pressure escape. You must also be aware of how your equipment functions under adverse circumstances. Run numerous computer simulations of various scenarios to achieve this. Last but not least, make sure everyone on the job site is always aware of the proper safety protocols in order to be prepared for any emergency.

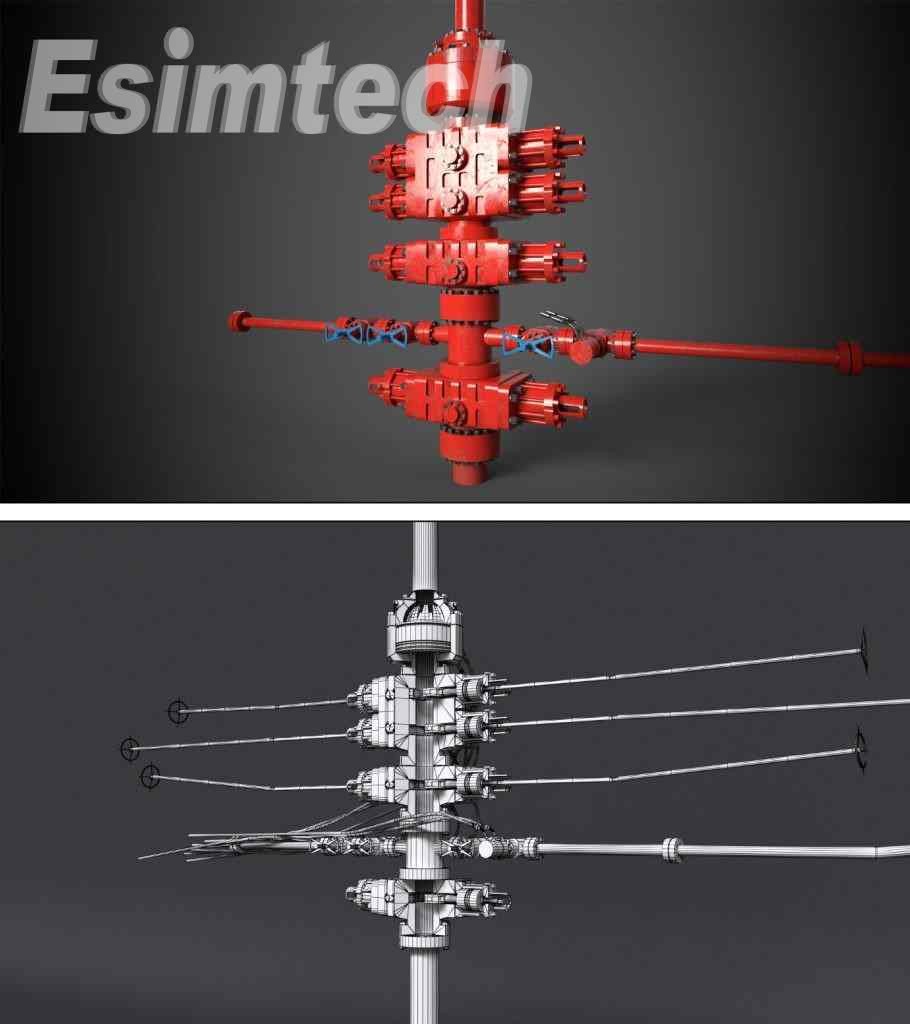

A Blowout Preventer

You should determine which kind of blowout preventer (BOP) is ideal for your application before making a purchase. You can pick between ram blowout preventers and annular blowout preventers, each of which has a crucial function. Your sector has a wide selection of new or used components and equipment, whether you need a BOP for a long-term project or current demands.

In a well, various BOPs with various functions may be utilized.

It is crucial to identify the issue, deal with it as soon as possible in a secure manner, and then take appropriate action.

Conclusion

Ensure that your staff members have the control tools and knowledge essential to know what to do in the event of a controllable kick. The best approach to handling a blowout is to make sure it doesn’t happen in the first place.

Esimtech is a manufacturer of drilling and well control simulation training systems that can aid qualified professionals. We manufacture whole oil and gas sector manufacturing lines as training simulators. If you have pertinent needs, get in touch with us.