What are Jack Up Rigs – Types, Functions, and Simulation Used for Them

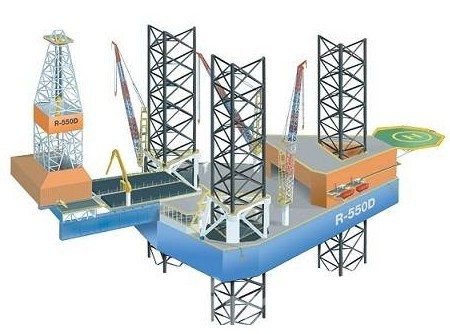

A jack-up rig, also known as a self-elevating unit, is a type of mobile offshore drilling platform. It consists of a buoyant hull fitted with a number of movable legs, capable of raising its hull over the surface of the sea. This allows the rig to operate in shallow water depths where other types of drilling platforms would not be able to function.

Here’s an overview of Jack Up Rigs:

Definition

- Jack-up rigs are floating platforms equipped with three or four retractable legs.

- These legs are lowered onto the seabed when reaching a desired location, elevating the platform above the water’s surface.

- This self-elevating feature allows jack-up rigs to operate in shallow waters where fixed platforms are not feasible.

Key Features and Advantages

- Versatility: Quick mobilization and deployment to various locations make them ideal for short-term projects or exploring new prospects.

- Cost-effectiveness: Lower construction and installation costs compared to fixed platforms, making them more cost-effective for shallow water drilling.

- Safety: Elevated platforms provide a stable and safe working environment for crew members, even in rough sea conditions.

- Accessibility: Jack-up rigs access shallower areas than other platforms, unlocking previously unreachable potential reserves.

Common Types of Jack Up Rigs

Several types of jack-up rigs exist, each with its own unique design and capabilities. Here are some of the most common:

1. Independent Leg Jack-up Rigs

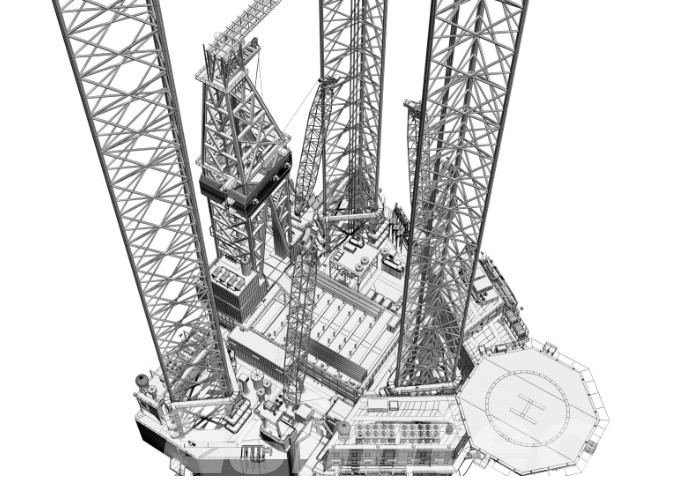

This is the most traditional type of jack-up rig, featuring three or four independent legs that are lowered individually onto the seabed.

Each leg is equipped with a jacking system, typically a rack and pinion mechanism, to raise and lower the platform.

Independent leg rigs are known for their simplicity and reliability but may not be suitable for very soft seabed conditions.

2. Mat-Supported Jack-up Rigs

This type incorporates a large mat foundation that spreads the weight of the rig over a wider area.

The mat distributes the load more evenly, making it suitable for softer seabed conditions where independent leg rigs might sink.

Mat-supported rigs offer greater stability and can support heavier loads, making them ideal for deeper water operations.

3. Caisson-Supported Jack-up Rigs

This design utilizes large hollow structures called caissons that are lowered onto the seabed and filled with water or ballast.

The caissons provide additional stability and allow for greater lifting capacity, making them suitable for even deeper waters and harsh environments.

Caisson-supported rigs are often more complex and expensive than other types but offer superior stability and load-bearing capacity.

4. Slot Jack-up Rigs

This type features a slot in the platform deck through which drilling operations take place.

This design allows for more efficient drilling, particularly for directional and horizontal drilling, as the drill bit does not need to be moved through the entire platform.

Slot jack-up rigs are often used for development drilling and completion operations.

5. Cantilever Jack-up Rigs

This design features a drilling derrick mounted on an extending arm, allowing for drilling beyond the footprint of the platform.

Cantilever rigs offer greater flexibility for well positioning and can access areas beyond the reach of the platform legs.

They are commonly used for exploration drilling and drilling in confined spaces.

Functions of Jack Up Rigs

Jack-up rigs are versatile platforms used in the offshore industry for various functions. Their ability to operate in shallow water and elevate themselves above the surface makes them valuable assets for exploration, development, and other offshore activities. Here are some of the primary functions of jack-up rigs:

1. Exploration Drilling

- Jack-up rigs are commonly used to drill exploratory wells to discover new oil and gas reserves in shallow waters.

- Their mobility and self-elevating capability allow them to operate quickly and efficiently in various locations.

- Exploration drilling helps identify potential reserves and assess their feasibility for development.

2. Development Drilling

- Once a discovery is made, jack-up rigs can be used to drill development wells to extract the oil and gas reserves.

- They provide a stable platform for drilling and production equipment, ensuring efficient and safe operations.

- Development drilling plays a crucial role in bringing discovered reserves to production and maximizing resource recovery.

3. Well Completion and Workover

- Jack-up rigs can be used to complete wells by installing production equipment and performing workover operations to maintain production.

- These operations involve various tasks like perforating the wellbore, installing production tubing and casing, and performing stimulation treatments.

- Well completion and workover ensure efficient production and extend the lifespan of producing wells.

4. Decommissioning

- Jack-up rigs can be used to decommission offshore platforms and pipelines once their productive life is over.

- They can remove equipment, dismantle structures, and clean up the seabed, ensuring environmental protection and responsible decommissioning.

- Decommissioning plays a vital role in closing down operations safely and minimizing environmental impact.

5. Wind Farm Construction

- Jack-up rigs are increasingly being used to install offshore wind turbines.

- Their stability and lifting capacity make them ideal for lifting and installing the heavy turbine components.

- This function contributes to the development of renewable energy sources and the transition towards a cleaner energy future.

6. Accommodation and Support

- Jack-up rigs can be used to provide accommodation and support services for offshore personnel.

- They can serve as temporary living quarters for crew members working on various offshore projects.

- Additionally, they can offer logistical support, storage space, and other essential services.

7. Scientific Research

- Jack-up rigs can support scientific research activities in various ways.

- They can provide a platform for researchers to study marine life, oceanography, and environmental conditions.

- Additionally, they can be used to deploy scientific equipment and conduct research projects in offshore locations.

Application of Simulation for Jack Up Rigs

Simulation has transformed jack-up rig drilling, offering immersive training for critical procedures like well control and emergency response simulation, reducing potential accidents. By optimizing drilling processes beforehand, it minimizes downtime and improves efficiency, leading to faster completion times and cost savings. Additionally, simulation provides a cost-effective training solution compared to traditional methods and contributes to overall cost reduction.

As technology advances, advanced simulation technologies and integration with other technologies will further enhance training effectiveness and operational efficiency. Simulation is essential for modern jack-up rig drilling, ensuring the success of offshore drilling projects and shaping the future of this critical industry.

Conclusion

Jack-up rigs are essential equipment for the offshore oil and gas industry. They are versatile and adaptable, and they can be used for a variety of tasks. Simulation is a valuable tool that can be used to improve the design, operation, and maintenance of jack-up rigs. As the offshore oil and gas industry continues to grow, jack-up rigs will continue to play an important role in the exploration and production of oil and gas.