How Rotary Steerable Systems Are Cutting Drilling Time by 30% or More

As energy companies strive for more cost-efficient drilling operations, Rotary Steerable Systems (RSS) have emerged as game-changing technologies. Recognized for improving directional drilling precision while simultaneously cutting non-productive time down significantly and speeding well delivery times up significantly, RSS tools are fast becoming standard among high-performance drillers worldwide. Let’s discover why they are revolutionizing the drilling industry – cutting drilling time by at least 30 %+ operations!

In this article, we’ll explore:

Understanding Rotary Steerable Systems

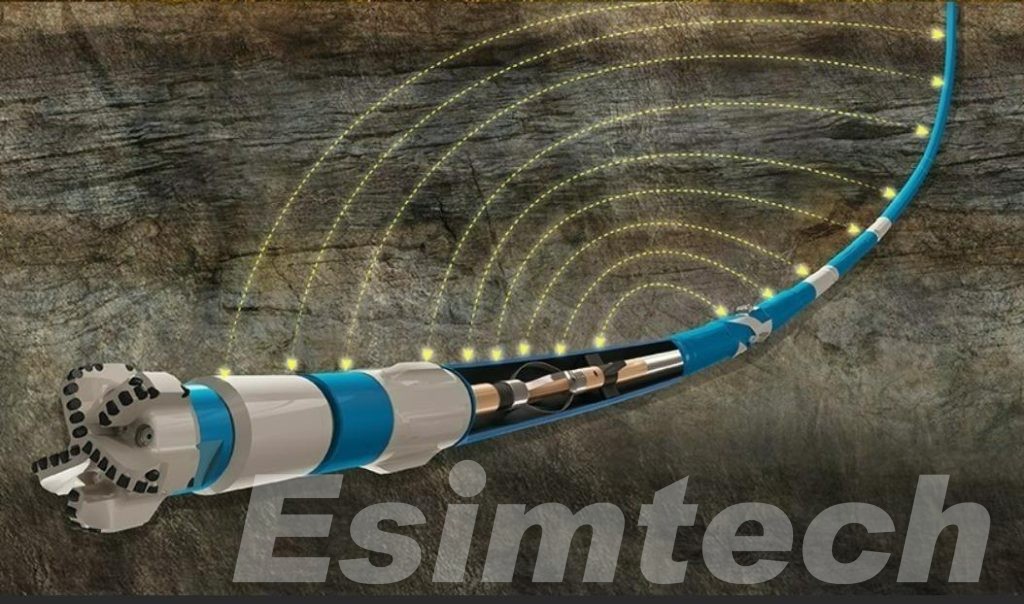

Rotary Steerable Systems (RSS) are advanced drilling technologies designed to steer the drill bit while the entire drill string continues to rotate. This is a major improvement over conventional steerable motors, which require intermittent stops and sliding to change direction. By maintaining continuous rotation, RSS enhances drilling efficiency, reduces mechanical stress, and improves wellbore quality.

There are two primary types of RSS: push-the-bit and point-the-bit. Push-the-bit systems use extendable pads to press against the borehole wall, while point-the-bit systems tilt the bit to alter its trajectory. Both methods allow for precise directional control, making it easier to follow complex well plans and reach challenging geological targets.

RSS tools are especially valuable in horizontal, deviated, and extended-reach wells, where accuracy and speed are critical. By integrating real-time telemetry and automated steering, RSS enables faster decision-making, reduces downtime, and significantly streamlines the drilling process, laying the groundwork for substantial time and cost savings.

Mechanism Behind Rotary Steerable Systems Efficiency

The efficiency of Rotary Steerable Systems (RSS) lies in their innovative design and ability to maintain continuous rotation while actively steering the drill bit. Unlike conventional steerable motors, which require periodic stops to slide the drill string and manually adjust direction, RSS allows for real-time directional control without interrupting drilling operations.

At the core of RSS efficiency are two primary steering mechanisms: “push-the-bit” and “point-the-bit.”

- Push-the-bit systems use expandable pads or pistons to apply force against the borehole wall, nudging the drill bit gently in its desired direction.

- Point-the-bit systems allow a tool to adjust internally the orientation of a bit so it travels precisely along its target path.

Both systems allow the drill string to continuously rotate from its starting position on the surface, which helps minimize mechanical issues like stick-slip, torque build-up, differential sticking, etc., which may slow drilling or cause tool damage in traditional setups.

Integral to RSS efficiency is its compatibility with real-time downhole telemetry and measurement-while-drilling (MWD) tools, which facilitate real-time tracking and immediate adjustments of well trajectory to ensure high precision drilling. Operators can steer the wellbore accurately while hitting tight geological targets and make course corrections without the risk of tripping out of the hole.

Continuous rotation also evens out wear evenly across the drill bit and string wear, prolonging tool life while decreasing tool change frequency. As a result, these features improve the rate of penetration (ROP) while decreasing non-productive time (NPT), both key metrics for measuring drilling performance.

By enabling smarter, faster, and smoother drilling, RSS technology dramatically improves overall drilling efficiency and is a vital component in today’s high-performance well construction strategies.

Why Rotary Steerable Systems Cuts Drilling Time by 30% or More

Rotary Steerable Systems (RSS) have become a cornerstone of efficient drilling operations, delivering time savings of 30% or greater compared to conventional methods. This dramatic reduction stems from several key technological and operational advantages that streamline the drilling process.

1. Continuous Rotation Enhances Drilling Speed

Unlike traditional mud motors that require stopping rotation to adjust direction (slide drilling), RSS allows for uninterrupted drilling while steering. This eliminates the downtime associated with slide corrections, maintaining optimal weight-on-bit and RPM for faster penetration. Field data shows that RSS can improve rate of penetration (ROP) by 20-50%, directly translating to shorter well cycles.

2. Reduced Tripping and Non-Productive Time (NPT)

With conventional systems, frequent adjustments require pulling out of the hole in order to switch tools or correct trajectory, adding hours or days onto drilling time. RSS minimizes these interruptions by offering real-time directional control without stopping, thus significantly cutting tripping time. Plus, smoother wellbores reduce risks like stuck pipe, excessive torque, or drag, further decreasing NPT.

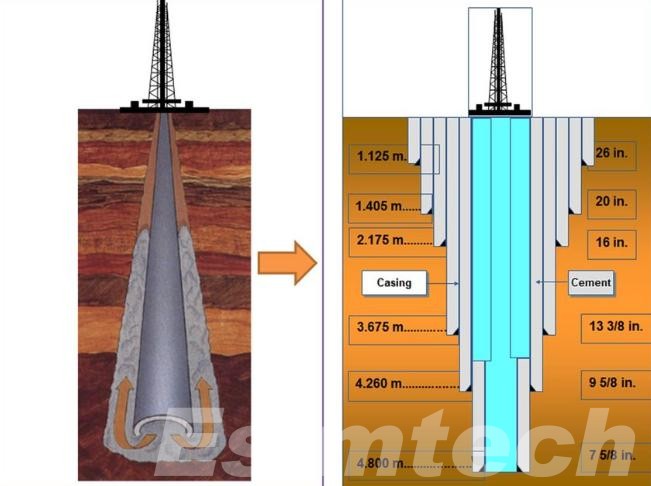

3. Improved Wellbore Quality & Fewer Complications

RSS produces wellbores that are less tortuous, leading to reduced frictional resistance on the drill string as well as mechanical strain on its components, ultimately leading to:

- Easier casing runs (without tight spots necessitating reaming)

- Reducing Wellbore Instability Issues and Hole Cleaning Concerns (RISE)

- Extended bit and tool lifespan (less wear from vibration)

4. Extended Reach and Complex Well Capability

RSS is well suited to drilling long laterals, horizontal wells, and complex trajectories, which would take too much time with traditional systems. By maintaining steering control while rotating, operators can drill faster without compromising accuracy, eliminating multiple runs or sidetracks altogether.

By integrating continuous rotation, automated steering, and real-time data feedback, RSS eliminates inefficiencies that slow traditional drilling. This results in 30%+ faster well delivery with reduced operational risks and substantial cost savings-making it essential for modern drilling programs.

Cost Savings & ROI of Rotary Steerable Systems

Rotary Steerable Systems (RSSs) have proven themselves effective time savers–often exceeding 30%–through uninterrupted drilling, improved trajectory control, and decreased mechanical dysfunction. Here’s how these advanced tools translate to faster well delivery:

- Continuous Rotation Eliminates Sliding

Traditional directional motors employ rotating and sliding modes to steer their bit, which disrupts drilling progress and diminishes the rate of penetration (ROP). RSS instead maintains full-bore rotation continuously so operators can steer “on the fly,” bypassing slow sliding phases completely to maintain optimal ROP while cutting hours or days off each drilling run.

- Precision Trajectory Management

RSS tools use real-time downhole measurements and high-speed telemetry to monitor the wellpath constantly and provide instantaneous feedback, enabling drillers to make minute, continuous corrections rather than large, delayed ones, helping the bit stay closer to its planned path, thus decreasing correction passes required and keeping the wellbore on target from start.

- Reduced Stick-Slip, Torque, and Drag

Stick-Slip, Torque and Drag Continuous rotation also mitigates stick-slip phenomena and excessive torque, which could otherwise result in sudden stoppages, bit damage, or tool failure. Because RSS applies subtle steering forces without stopping the drill string, its reduced mechanical stresses decrease downhole. Less time spent changing bits or performing maintenance also means increased time spent actively drilling!

- Reduce Non-Productive Intervals

With RSS, all directional adjustments, coring operations, and sidetracks occur within one run, eliminating trip-outs for bit reorientation or corrective drilling, thus significantly decreasing non-productive time (NPT) spent drilling complex wells, such as long reach horizontals or highly deviated section, can save considerable NPT and also contribute towards schedule compression.

- Optimized Bit and BHA Performance

The stable drilling environment fostered by RSS prolongs bit life and protects bottomhole assembly (BHA) components from excessive wear. Healthier downhole tools maintain higher ROP for longer durations, further compounding time savings over the life of the well.

By combining uninterrupted drilling, precise steering, and reduced mechanical wear, Rotary Steerable Systems cumulatively cut cycle times by 30% or more—delivering wells faster and at lower overall cost.

Conclusion

Rotary Steerable Systems are revolutionizing the drilling industry by cutting drilling times by up to 30% and significantly improving wellbore quality while simultaneously cutting operational costs. Thanks to features like faster ROP times, reduced trips taken, extended reach capabilities, and superior returns on investment (ROI), RSS technology provides operators with a strong return on their efficiency investments.

As drilling becomes ever more complicated and cost pressures rise, RSS adoption no longer represents just an optional choice; rather, it has become essential in modern oil and gas operations.