Using Well Logging Simulators for Open Hole and Cased Hole Training

Training of well logging engineers has always been a challenge. Open hole and cased hole logging involve different tools, workflows, risks, and decision points, with most training programs still depending on classroom instruction with limited field exposure. This is where well logging simulators really make a difference-not as a replacement for field work, but to prepare engineers before they step onto the rig.

This article simply answers the question of how to effectively use well logging simulators in training for both open hole and cased hole operations.

Why Open Hole and Cased Hole Well Logging Training Needs Simulation

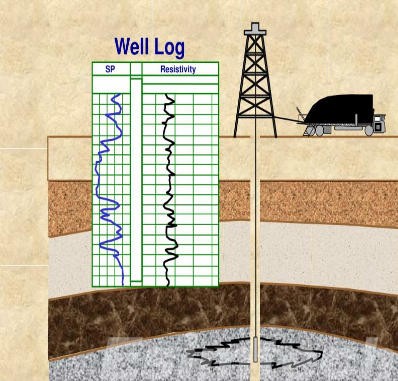

The process of open hole logging requires trainees to manage four main challenges which include unstable formations and borehole enlargements and mud invasion and tool sticking risks. Cased hole logging requires engineers to address three main challenges which include casing effects and cement quality issues and tool centralization and limited formation exposure. Teaching these differences only through slides or manuals is slow and inefficient.

A simulator gives instructors the ability to create these specific conditions whenever they need to. Trainees can see how the same logging tool behaves differently in open hole versus cased hole, and more importantly, why the data looks the way it does. The system enables users to acquire essential knowledge while reducing the possibility of expensive errors which occur during field operations.

How Simulators Support Both Open Hole and Cased Hole Logging Training

Open hole logging and cased hole logging have different thinking processes. However, it is most effective when both are learned. A well logging training simulator provides engineers an opportunity to work on a single well in a virtual scenario and see the responses change once the casing is set, rather than having to learn each one individually.

Open Hole Logging Training: Borehole Conditions and Tool Control

The level of attention to how conditions within the borehole directly impact the quality of the log is the primary focus of the training using open-hole logging simulators.

When the quality of log data deteriorates, real decisions are made. These decisions include changing the rate of log data acquisition or redoing the log. These decisions help trainees realize that open hole logging is not just data acquisition; it is a process of continuous assessment based on borehole behavior.

Cased Hole Logging Training: Casing Effects and Interpretation Skills

Training provided in cased hole logging focuses attention away from direct exposure of the formation to casing, cement, and tools. The cased hole well logging simulator demonstrates the effect of cement bonding, channeling, and tool eccentering, even where curves appear clean.

By comparing cased hole logs with open hole log data from the same interval, trainees will gain an understanding of what information is lost, changed, or remains usable with regard to formation information. This will also enhance their interpretation skills for cement, production logging, and monitoring jobs.

Using a well logging simulator for open hole and cased hole well logging training, companies specializing in petroleum exploration and extraction operations can significantly minimize errors, training period, and enhance the confidence of their engineers in the actual well logging operations.

Training Progression: From Simple to Complex Scenarios

A major advantage of simulation-based training is its structured progression. Instructors often start with clean, ideal wells and gradually add complexity. This mimics how engineers become proficient in a field.

A possible pattern of the training process might follow this course:

- Simple vertical open hole with stable formation

- Open Hole with Washouts and Invasion Effects

- Cased Hole with a good cement job and clean signals

- Cased hole with poor cement job, channeling, or tool eccentricity.

For advanced scenarios, trainees are by then comfortable with the tools and workflows, so the simulator now acts as a problem-solving medium.

Open Hole vs Cased Hole: What Trainees Learn Differently

The table below highlights how simulators help trainees distinguish between open hole and cased hole operations during training:

| Aspect | Open Hole Training Focus | Cased Hole Training Focus |

| Data quality | Borehole condition impact | Casing and cement effects |

| Tool handling | Sticking and washout risks | Centralization and eccentering |

| Interpretation | Formation response | Signal correction and inference |

| Decision-making | Logging speed and repeats | Tool selection and positioning |

This side-by-side understanding is difficult to achieve without simulation.

Reducing Field Errors Through Simulator Practice

One of the clearest benefits of simulator-based training is fewer field mistakes. Engineers who have trained on simulators are more confident during real operations. They recognize abnormal logs faster and react with intention rather than guesswork.

Instead of asking basic questions at the wellsite, they already understand the relationship between environment, tool behavior, and data response. This reduces non-productive time and improves overall job quality, especially in high-cost offshore or complex onshore wells.

Why Service Companies and Training Centers Use Simulators

In service-based businesses, the simulator also assists in the standardization of training. Every trainee will go through the same scenarios and will be evaluated by the same parameters. It is not easy to standardize the training process only through the field.

Simulators also have several benefits for training centers and training operators, as trainees here are provided with a chance to practice by repeating the same well, thereby creating improvements without any operational risk, as is sometimes posed by real wells drilled.

Well logging simulators assist engineers in getting the right skills to make them job-ready even before they arrive at the job site. By doing this, they gain more confidence and make the right decisions.

The well logging simulator is designed to accommodate open-hole and cased-hole training on the same platform. This gives the trainees an opportunity to repeat the entire well, address specific issues, and learn through repetition without posing any risk.

If you want to improve training efficiency or standardize well logging training across teams, contact us to learn more or request a demo.

You can also see demos at out Youtube channel: https://www.youtube.com/@esimtechtrainingsimulator3874