Unconventional Oil and Gas Development Trends: Is Horizontal Drilling Still the Core?

In the development of unconventional oil and gas resources such as shale oil, shale gas, and tight oil and gas, horizontal drilling has almost been regarded as the “standard technology”. However, as the development progresses to the middle and later stages, with increasing cost pressure and the continuous maturation of digital technology, the industry has begun to consider a realistic question: In the future development of unconventional oil and gas, will horizontal drilling still be the core?

The answer is clear: Horizontal drilling is not only still the core, but is also constantly upgrading and evolving, becoming the “ballast stone” for the efficient, economic and large-scale development of unconventional oil and gas.

Why Unconventional Oil and Gas Development Depends on Horizontal Drilling

Unconventional reservoirs maintain their characteristic features which include their low porosity, low permeability, and extensive heterogeneity. Traditional vertical wells cannot access enough rock depth to produce economically viable extraction results. Horizontal wells provide greater operational advantages than vertical wells because they create extended open-hole or completion sections that enhance reservoir contact through their extended reach into target layers. This is especially vital for shale gas operations and tight oil extraction processes.

Current Trend: Horizontal Drilling is No Longer Merely “Drilling a Single Horizontal Well”

In the early stage of unconventional oil and gas development, the industry focused on the question of “whether oil and gas could be produced”; now, however, it pays more attention to whether it can be developed stably, efficiently and in a replicable manner.

Horizontal Section: From “Long” to “Extra Long”, Limitless Extension Breaking Boundaries

North America is the region with the most mature development of unconventional oil and gas globally. The horizontal sections of shale wells are generally 3,000 to 4,000 meters long, and the pioneering wells in the core production areas have even approached 5,000 meters. The deployment of the core is not aimed at length but rather combines reservoir characteristics to maximize the reservoir coverage of a single well and enhance the development value.

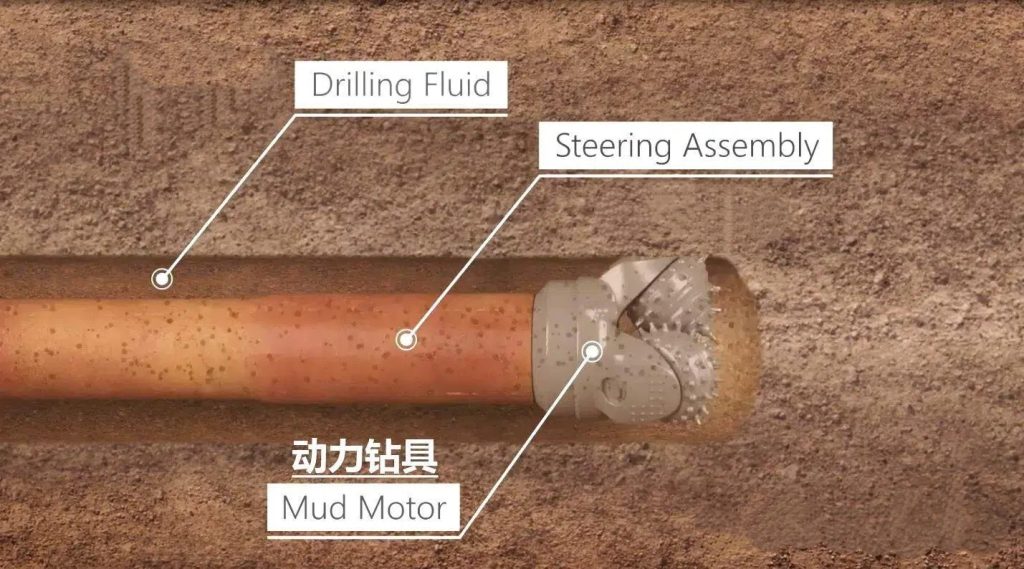

Drilling: From “Manual” to “Intelligent” – Precise and Efficient Improvement

Traditional horizontal drilling relies on manual experience, which has the drawbacks of low precision, large fluctuations in efficiency, and high accident rates. With the integration of AI, automation technology and drilling engineering, horizontal drilling has entered the “intelligent era”, with the core being to achieve precise guidance, efficient drilling, and safe control. Intelligent guidance can increase the reservoir drilling rate by more than 15%, reduce production loss, and lower operational errors.

Well Network: From “Two-Dimensional” to “Three-Dimensional” – Enhancing the Quality and Efficiency of One Well for Multiple Productions

The traditional planar well pattern has problems such as insufficient utilization of reservoirs, excessive land occupation, and low efficiency. Nowadays, the well pattern has been upgraded to a three-dimensional interlaced pattern, achieving multi-well collaboration and one well producing multiple products through innovative models, thereby enhancing development efficiency. This model is centered on “centralized deployment, shared facilities, and collaborative mining”, with dozens of three-dimensional interlaced horizontal wells deployed on the same platform, forming a “well factory” layout.

The branch horizontal wells are drilled from the main horizontal wells to create multiple short-radius branches, forming a “main well + multiple branches” structure. The core is to expand reservoir contact and revitalize old well resources.

Are There Any Technologies That Can Replace Horizontal Drilling?

In the short to medium term, no emerging technology can replace horizontal drilling. Radial drilling, advanced proppants or enhanced oil recovery (EOR) are all auxiliary tools – they can enhance production efficiency, but still require the use of horizontal wellbores to function.

Even in the context of the energy transition, unconventional oil and gas will continue to play a key role in providing reliable and low-carbon fossil energy. Horizontal drilling will continue to adapt to development needs, becoming more efficient, more automated, and more environmentally friendly.

Conclusion

Horizontal drilling stands as the fundamental technique used for developing unconventional oil and gas resources. The method serves as the essential technical base which enables the extraction of tight reservoirs while producing profitable results through extensive production activities. The future of unconventional resources depends on enhancing horizontal drilling through longer operational capabilities and advanced intelligent systems and exact measurement methods and environmentally friendly practices.

After the entry of unconventional oil and gas development into the refined stage, the challenges of horizontal drilling are no longer limited to “whether it can be drilled to the right position”, but focus on well control safety, operational coordination, and team cooperation. In high-investment projects such as shale oil and shale gas, simulation training is gradually shifting from an “optional” option to a “part of risk management”.