Shear Rams vs Blind Rams: What are the Differences and How to Select

Blowout preventers (BOPs) are essential safety devices used in oil and gas drilling to prevent blowouts, which are uncontrolled releases of oil, gas, or other fluids from a well. Shear rams and blind rams are two of the most important components of a BOP stack.

Overview of Shear Rams and Blind Rams

Shear Rams

Shear rams are designed to shear through drill pipe and tubing in the event of a blowout. This helps to prevent the uncontrolled release of oil and gas from the wellbore. Shear rams have two or three blades that are made of a hard and durable material, such as tungsten carbide. The blades are designed to shear through drill pipe and tubing of any size.

Shear rams are typically used in conjunction with blind rams to provide a complete seal on the wellbore. Once the shear rams have sheared through the drill pipe and tubing, the blind rams can be used to seal the wellbore and prevent any further flow of oil and gas.

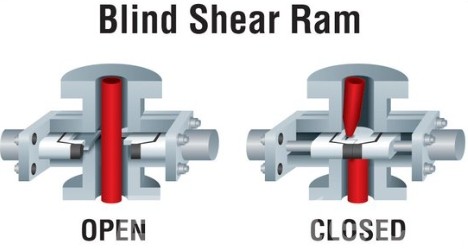

Blind Rams

Blind rams are designed to seal the wellbore in the event of a blowout, regardless of whether or not there is drill pipe or tubing in the wellbore. Blind rams have two or three rubber seals that are designed to create a watertight seal on the wellbore.

Blind rams are typically used in conjunction with shear rams to provide a complete seal on the wellbore. However, blind rams can also be used on their own to seal the wellbore if there is no drill pipe or tubing in the wellbore.

Differences Between Shear Rams and Blind Rams

The following table summarizes the key differences between shear rams and blind rams:

| Characteristic | Shear rams | Blind rams |

| Function | Shear through drill pipe and tubing | Seal the wellbore, regardless of whether or not there is drill pipe or tubing in the wellbore |

| Design | Blades | Rubber seals |

| Advantages | More effective at sealing the wellbore | Less likely to damage the wellbore |

| Disadvantages | Can damage the wellbore | Not as effective at sealing the wellbore |

| Cost | More expensive | Less expensive |

Advantages and Disadvantages of Shear Rams and Blind Rams

Shear Rams

Advantages:

- More effective at sealing the wellbore than blind rams

- Can be used to shear through drill pipe and tubing, which can help to prevent the uncontrolled release of oil and gas

- Can be used in conjunction with blind rams to provide a complete seal on the wellbore

Disadvantages:

- Can damage the wellbore

- More expensive than blind rams

Blind Rams

Advantages:

- Less likely to damage the wellbore than shear rams

- Less expensive than shear rams

- Can be used to seal the wellbore, regardless of whether or not there is drill pipe or tubing in the wellbore

- Can be used in conjunction with shear rams to provide a complete seal on the wellbore

Disadvantages:

- Not as effective at sealing the wellbore as shear rams

- Cannot be used to shear through drill pipe and tubing

How to Select Between Shear Rams and Blind Rams

To select between shear rams and blind rams, the following factors should be considered:

- Risk of blowout: If the risk of a blowout is high, shear rams should be used because they are more effective at sealing the wellbore.

- Condition of the wellbore: If the wellbore is weak or damaged, blind rams should be used because they are less likely to further damage the wellbore.

- Need to shear through drill pipe or tubing: If there is a need to shear through drill pipe or tubing, shear rams must be used.

- Cost: Shear rams are more expensive than blind rams.

In general, shear rams and blind rams are used together to provide the most effective seal on the wellbore. However, if the risk of damaging the wellbore is high, blind rams may be used on their own.

Drilling Simulation technology can be used to help select between shear rams and blind rams. Simulation software can be used to model the wellbore and the BOP stack to predict how the different types of BOP rams will perform under different conditions. This information can be used to select the best type of BOP ram for the specific needs of the well and to reduce the risk of accidents.

For example, simulation software can be used to predict the following:

- The force required to shear through drill pipe or tubing of different sizes and materials

- The amount of damage that shear rams will cause to the wellbore

- The effectiveness of blind rams at sealing the wellbore under different conditions

Simulation software can also be used to train BOP operators on how to use the different types of BOP rams safely and effectively. This training can help to reduce the risk of human error and improve the overall safety of BOP operations.

Conclusion

Shear rams and blind rams are both important components of a BOP stack. Shear rams are more effective at sealing the wellbore than blind rams, but they can also damage the wellbore. Blind rams are less likely to damage the wellbore than shear rams, but they are not as effective at sealing the wellbore. Shear rams are more expensive than blind rams.

When choosing between shear rams and blind rams, it is important to consider the specific application. If the primary goal is to seal the wellbore, then shear rams are the better choice. If the primary goal is to avoid damaging the wellbore, then blind rams are the better choice.

In addition, you can also consider simulation technology to help you make your choice.