The Most Common Wireline Logging Tools and Their Uses

Wireline logging is a must-have step in oil and gas projects. It sends special tools down a borehole to collect clear data about rock layers, show where hydrocarbons sit, and help teams fine-tune how much oil or gas a well can produce.

In this post, we'll break down what wireline logging is, walk through its most-used tools and what each one does, and touch on the newest tech trends making these jobs faster and more accurate.

Basics of Wireline Logging

Wireline logging has been a go-to method in the oil and gas world for pulling key data from below the surface. By sending heavy-duty cables down a well, crews can attach clever tools that check everything from rock type to the amount of oil or gas trapped inside.

After a well is drilled or even while it is producing, the sensor-packed equipment is slowly lowered in, one section at a time. As each sensor takes a reading, the information shoots back up the line, creating a real-time picture of what the ground looks like. Wireline logging usually happens after the drill pipe is pulled, which lets the instruments work slowly enough to catch detail that the drill bit might shake loose.

Key Benefits of Wireline Logging

- Formation Evaluation: pinpoints where hydrocarbons sit and tells oil from gas and water.

- Reservoir Characterization: looks at porosity, permeability, and rock mix to rate the reservoir's upside.

- Well Integrity Analysis: spots rust on pipe, weak cement, and other trouble spots that threaten a well.

- Geosteering & Correlations: lines up data from one well with another, helping drill teams stay on track.

Wireline logging saves money by steering planning, cutting the chances of drilling blind, and keeping wells flowing longer. With smarter sensors and faster computers, today's wireline jobs deliver sharper, easier-to-read facts that teams can act on right away.

Common Types of Wireline Logging Tools

In the field of wireline logging, several specialized instruments consistently provide the detailed information geoscientists seek about underground rock layers. Gamma-ray, density, sonic, and neutron logs together create the core dataset for borehole evaluation, with each tool offering unique but mutually supportive measurements.

Gamma-Ray Tool

The gamma-ray tool is arguably the most commonly run instrument, valued for its straightforward operation and reliable results. It counts the natural gamma photons released by isotopes of potassium, thorium, and uranium in the rock, producing a smooth log that marks shale-heavy intervals and potential hydrocarbon zones. Elevated gamma counts usually signal clay-rich formations, whereas lower values suggest clean sandstones or carbonates. Because of this clear response, the gamma-ray log is routinely used for quick rock-type checks, linking different wells across a field, and mapping the first-order contacts between layers.

Density Logging Tool

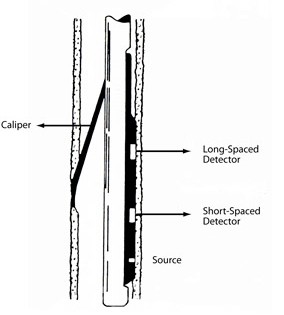

Following closely in the suite of wireline measurements, the Density Logging Tool employs a sealed radioactive source and paired detectors to record how many electrons each cubic centimeter of rock intercepts. Because electron density closely tracks bulk density, loggers translate these counts into raw density numbers that, when compared against known matrix and fluid densities, lead directly to porosity estimates. Operators routinely rely on density records to tell apart tight, impermeable formations from more open reservoirs, and to trace subtle shifts in lithology across the borehole. Joined with complementary tools, the density curve tightens calculations of hydrocarbon saturation and adds depth to overall reservoir models.

Sonic Logging Tool

Colloquially called the acoustic or waveform tool, the Sonic Logging Tool measures the time it takes sound waves to cross a segment of formation. Because wave speed varies with mineral make-up, porosity, and the type of filling fluid, the sonic log acts as a multitask gauge of mechanical strength and petrophysical character. Generally, high velocities point to dense, low-porosity lithologies, whereas slower arrivals hint at more open, potentially hydrocarbon-bearing intervals. Beyond porosity checks, sonic data underpins geomechanical studies by enabling engineers to size up rock strength ahead of drilling, completion, and staged fracturing operations.

Neutron Logging Tool

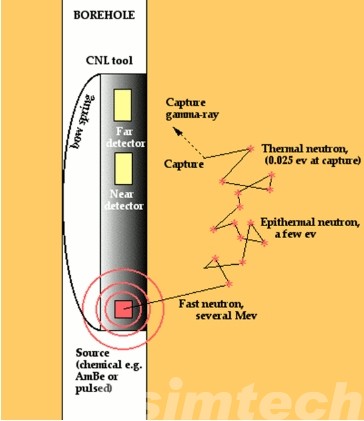

The Neutron Logging Tool is prized in the industry for its ability to gauge hydrogen content, a measurement that ties closely to pore space filled with liquid. When high-energy neutrons released by the logging source collide with hydrogen nuclei, they lose speed and in the process generate low-energy gamma rays that the tool’s detectors record. Analysing these count rates, petrophysicists extract porosity numbers that reveal subtle differences between gas-saturated and liquid-saturated rocks. Because neutrons respond differently in formations containing gas, this log is routinely paired with density readings; the crossplot of the two curves then becomes a reliable fingerprint for identifying zones filled with gas, oil, or water. Through this cooperative analysis, neutron logging has earned its place in every complete wireline campaign.

Combined with the other three primary logging devices, the neutron tool rounds out a rich, multiangular dataset, empowering exploration teams to reconstruct the reservoir with high fidelity and to plan interventions that maximise production efficiency.

Applications and Uses of Wireline Logging Tools

Wireline logging tools sit at the heart of well development and reservoir management, giving operators the clear, precise data they need to make smart choices at every step:

1. Formation Evaluation

By measuring things like rock density, natural radioactivity, sound speed, and hydrogen content, wireline tools paint a picture of lithology, porosity, and fluid saturation. Geoscientists then mark likely pay zones, rough out hydrocarbon volumes, and fine-tune reservoir models long before any drill bit bites.

2. Well Integrity Monitoring

Steel casing and cement must keep the well sealed to protect people and the environment. Tools like caliper logs and cement-bond logs search for dents, corrosion, or voids behind the pipe. Catching these flaws early can save operators money and avoid spills or blowouts down the road.

3. Completion and Stimulation Design

When the well is almost finished, fresh logs tell engineers exactly where to perforate and how to fracture the rock. Scene-setters such as density-neutron crossplots show high-porosity strips, while sonic logs reveal rock stiffness for crack modeling. These insights stretch well beyond life and lift overall recovery.

4. Reservoir Surveillance

Years later, running the same tools again shows how pressure, fluid contacts, and saturation have changed. That time-lapse, sometimes called “4D logging,” outlines production-induced shifts so operators can tweak injection rates and chase extra oil.

5. Hydrocarbon Detection and Differentiation

To tell apart gas, oil, and water zones in a well, people often cross-plot neutron logs against density logs. They use gamma-ray readings to mark shale edges and rely on resistivity logs to show where fluids let electricity pass. When all these curves are looked at together, engineers can locate and measure hydrocarbon-bearing layers with high confidence.

Pulling insights from several wireline tools helps engineers and petrophysicists create a clear, 3D picture of the rocks underground. This complete view sharpens reservoir mapping, guides smarter production plans, and cuts uncertainty, making drilling quicker and more profitable for oil and gas projects.

Advances in Wireline Logging Technology

The oil and gas world never stops changing, and the kit used for wireline logging is no exception. Recent tech leaps have made logging tools faster, more accurate, and more flexible, helping teams plan and respond in tougher drilling spots.

- Real-time data streaming stands out as a game changer. Today’s wireline rigs use high-speed telemetry that beams downhole readings to the surface almost instantly. With this live feed, engineers can tweak speeds, spot problems early, and move ahead with confidence.

- Multi-sensor workhorses are another major advance. Instead of sending separate logs for gamma-ray, density, neutron, and resistivity, these small units bundle the measurements into one run. That cuts trips, shrinks the slick, and trims overall costs.

- High-resolution digital gear captures finer details, improving formation images and honing reservoir maps. On top of that, machine learning now scans the numbers, spots hidden trends, and sharpens forecasts, saving busy analysts hours of manual review.

Together, these upgrades steer the industry toward smarter, data-driven drilling and production. As the hardware keeps pacing the software, wireline logging will keep delivering fresh insights from spud to abandonment.

Final Thought

Knowing how each wireline logging tool works makes well evaluation and reservoir management a lot smoother. Gamma-ray devices show rock type, while neutron-density pairs estimate porosity; every instrument adds a key piece to the puzzle.

Wires, logging is getting smarter, delivering sharper, more useful data that the oil and gas sector can act on right away.

When firms pick the correct tools, they fine-tune exploration, lower exposure to surprises, and boost overall production efficiency.