The Pivotal Role of Managed Pressure Drilling Techniques for Well Intervention Operations

Managed Pressure Drilling (MPD) techniques have emerged as powerful tools for conducting well intervention operations in the oil and gas industry. Traditionally used during drilling, Managed Pressure Drilling has expanded its application to encompass various forms of well intervention, including well control, wellbore strengthening, reservoir stimulation, and production optimization. This article explores the significance of MPD drilling techniques in well intervention operations, their applications, benefits, and the crucial role in the implementation and optimization of Managed Pressure Drilling techniques for well intervention operations.

A Basic Overview of Managed Pressure Drilling for Well Intervention Operations

This chart provides a concise overview of Managed Pressure Drilling (MPD) for well intervention operations

| Aspect | Description |

| Definition | Managed Pressure Drilling (MPD) is a specialized drilling technique used in well intervention operations, where bottom hole pressure is precisely controlled to prevent influxes of formation fluids or gas kicks. |

| Objective | The primary objective of MPD in well intervention is to enhance drilling safety, efficiency, and productivity by maintaining precise control over wellbore pressure, optimizing drilling parameters, and mitigating drilling hazards. |

| Techniques | Managed Pressure Drilling techniques for well intervention include Underbalanced Drilling (UBD), Constant Bottomhole Pressure (CBHP), Pressurized Mud Cap Drilling (PMCD), and Dual Gradient Drilling (DGD), each tailored to specific operational requirements and objectives. |

| Applications | Managed Pressure Drilling is applied in various well intervention operations, including well control, wellbore strengthening, reservoir stimulation, production optimization, and remediation activities. |

| Benefits | The benefits of MPD drilling for well intervention include enhanced safety, improved operational efficiency, maximized reservoir recovery, minimized environmental impact, and increased drilling success rates. |

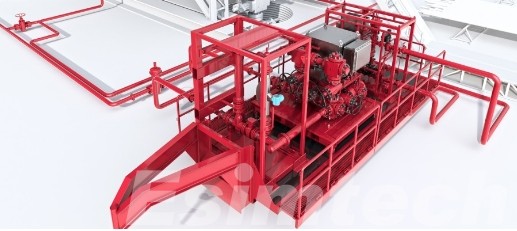

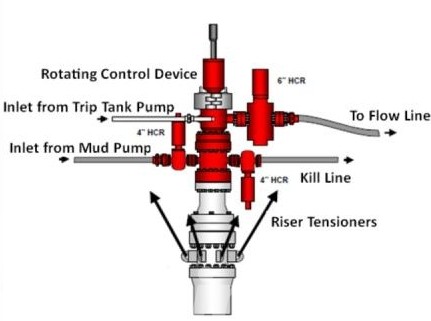

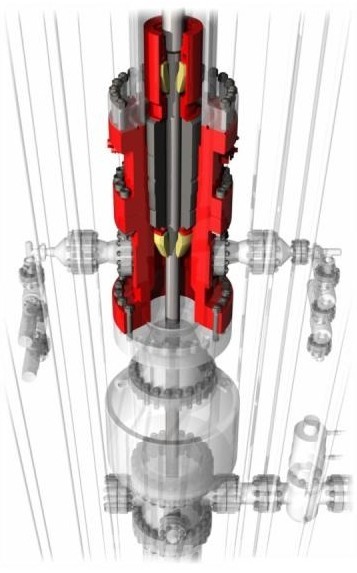

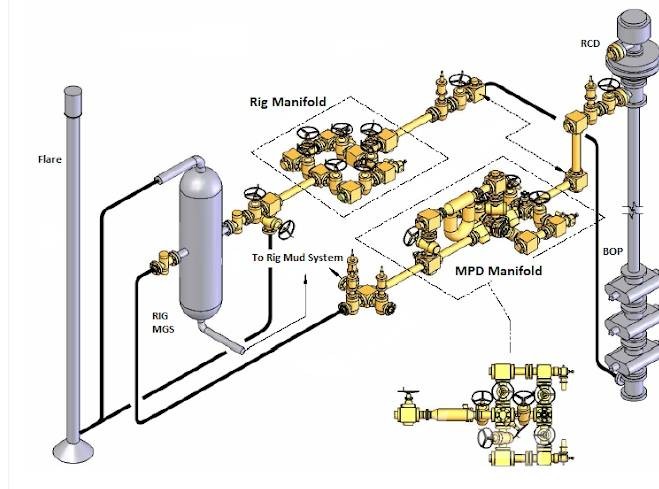

| Components | MPD systems for well intervention comprise key components such as a choke manifold, MPD unit, surface pressure control equipment, downhole pressure tools, and advanced monitoring and control systems. |

| Challenges | Challenges associated with MPD drilling for well intervention include equipment complexity, specialized training requirements, regulatory compliance, operational integration, and upfront investment costs. |

| Future Trends | Future trends in MPD for well intervention include advancements in automation, integration with digital technologies, development of standardized protocols, expansion into new drilling environments, and increased adoption of MPD drilling techniques. |

How Managed Pressure Drilling Techniques are Used for Well Intervention Operations

1. Well Control and Kick Prevention

- Managed Pressure Drilling techniques are employed to precisely control bottom hole pressure, maintaining it within a narrow operational window to prevent influxes of formation fluids or gas kicks during well intervention activities.

- By dynamically adjusting annular pressure and flow rates, MPD systems can promptly detect and manage kicks, enhancing well control and minimizing the risk of blowouts or well control incidents.

2. Underbalanced Drilling (UBD)

- Underbalanced drilling, a form of MPD, involves maintaining the wellbore pressure lower than the formation pressure, allowing reservoir fluids to flow into the wellbore.

- In well-intervention operations, UBD techniques can be utilized to minimize formation damage, enhance reservoir productivity, and facilitate the recovery of valuable hydrocarbons during workover, completion, or stimulation activities.

3. Wellbore Strengthening and Stabilization

- MPD drilling techniques are employed to stabilize the wellbore and mitigate wellbore instability issues during well intervention operations such as wellbore cleanouts, casing milling, or perforation.

- By maintaining precise control over wellbore pressure gradients, MPD helps prevent wellbore collapse, fluid losses, and formation damage, ensuring the integrity and stability of the wellbore.

4. Reservoir Stimulation

- In well intervention operations aimed at reservoir stimulation, such as hydraulic fracturing or acidizing, Managed Pressure Drilling is utilized to control bottom hole pressure and optimize fluid injection rates.

- By maintaining wellbore pressure within the desired range, MPD facilitates effective reservoir stimulation, ensuring the successful creation and propagation of fractures or the dissolution of formation minerals.

5. Production Optimization

- MPD techniques can be used to perform production optimization interventions like as wellbore cleanouts, sand control operations, and artificial lift optimization.

- Managed Pressure Drilling improves production efficiency, optimizes fluid recovery, and minimizes formation damage, resulting in higher productivity and longer well life.

3. Wellbore Integrity Assessments

- MPD drilling techniques are employed for wellbore integrity assessments during well intervention activities such as well logging, casing inspection, or cement evaluation.

- By controlling wellbore pressure and monitoring downhole conditions, MPD helps identify potential integrity issues, ensuring the integrity and reliability of the wellbore.

Simulation Technology Used in Managed Pressure Drilling for Well Intervention Operations

1. Dynamic Pressure Modeling

Simulation software is used to model and simulate dynamic wellbore pressure profiles during Managed Pressure Drilling operations. Simulation models estimate bottom hole pressure changes in real-time using data on wellbore shape, fluid characteristics, and drilling parameters, allowing operators to optimize pressure management tactics and reduce drilling risks.

2. Risk Assessment and Scenario Analysis

Simulation tools examine potential drilling risks and vulnerabilities by doing scenario analyses to determine the effect of various wellbore conditions and drilling settings on pressure control. By simulating various drilling scenarios and contingencies, operators can identify potential hazards and develop proactive risk mitigation strategies.

3. Hydraulic Analysis and Flow Modeling

Simulation software performs hydraulic analysis and flow modeling to optimize fluid circulation rates, wellbore pressure gradients, and annular pressure profiles during Managed Pressure Drilling operations. By simulating fluid flow dynamics in the wellbore, simulation models help optimize drilling fluid properties, minimize fluid losses, and enhance wellbore stability.

4. Equipment Performance Evaluation

Simulation technology evaluates the performance of MPD equipment and components, including choke manifolds, pressure control valves, and surface pressure control equipment. By simulating equipment behavior under different operating conditions, operators can identify potential equipment limitations, optimize equipment configurations, and ensure operational reliability.

5. Training and Operator Competency

Simulation software provides drilling training simulators with virtual reality environments for MPD operators and drilling personnel. By simulating realistic drilling scenarios and wellbore conditions, training simulators enable operators to practice pressure control techniques, emergency response procedures, and well control operations in a safe and controlled environment.

6. Decision Support and Optimization

Simulation tools work together with decision support systems to deliver real-time data insights and optimization suggestions for MPD drilling operations. Simulation models analyze real-time drilling data to discover trends, predict future wellbore conditions, and offer the best pressure control tactics for improved drilling safety and efficiency.

Conclusion

Managed pressure drilling techniques have transformed well intervention operations in the oil and gas industry, offering unparalleled control over wellbore pressures and mitigating drilling risks. By offering precise control over wellbore pressure, MPD improves safety, efficiency, and productivity, allowing operators to optimize well intervention activities and maximize reservoir recovery.

Simulation technology is critical in the design, implementation, and optimization of Managed Pressure Drilling techniques for well intervention operations. Well intervention simulation tools enable operators to optimize pressure control strategies and ensure the success of well intervention activities in the oil and gas industry.