The Significant Role of Technology in Improving Drilling Safety

Technology is playing an increasingly important role in improving drilling safety. New technologies are being developed to help identify and mitigate hazards, improve training and communication, and enhance emergency response.

Ways Technology Being Used to Improve Drilling Safety

Wellbore Control

Wellbore control is the process of preventing the uncontrolled flow of oil and gas from a wellbore. Wellbore accidents can be very dangerous, and they can also release large amounts of oil and gas into the environment.

One way that technology is being used to improve wellbore control is through the use of automated well control systems. Automated well control systems can monitor wellbore conditions and take corrective action in the event of a problem. For example, an automated well control system can close the blowout preventer (BOP) if it detects a sudden increase in well pressure.

Another way that technology is being used to improve wellbore control is through the use of real-time monitoring systems. Real-time monitoring systems can collect data from a variety of sensors on the drilling rig and transmit this data to a central control center. This data can be used to monitor wellbore conditions and identify potential problems early on.

H2S Safety

Hydrogen sulfide (H2S) is a toxic gas that can be present in oil and gas wells. H2S exposure can lead to serious health problems, including death.

One way that technology is being used to improve H2S safety is through the use of real-time H2S monitoring systems. Real-time H2S monitoring systems can continuously monitor the air for the presence of H2S. If H2S is detected, the system can alert workers and activate ventilation systems to remove the gas from the air.

Another way that technology is being used to improve H2S safety is through the use of personal protective equipment (PPE). PPE for H2S exposure includes respirators, gas detectors, and escape hoods.

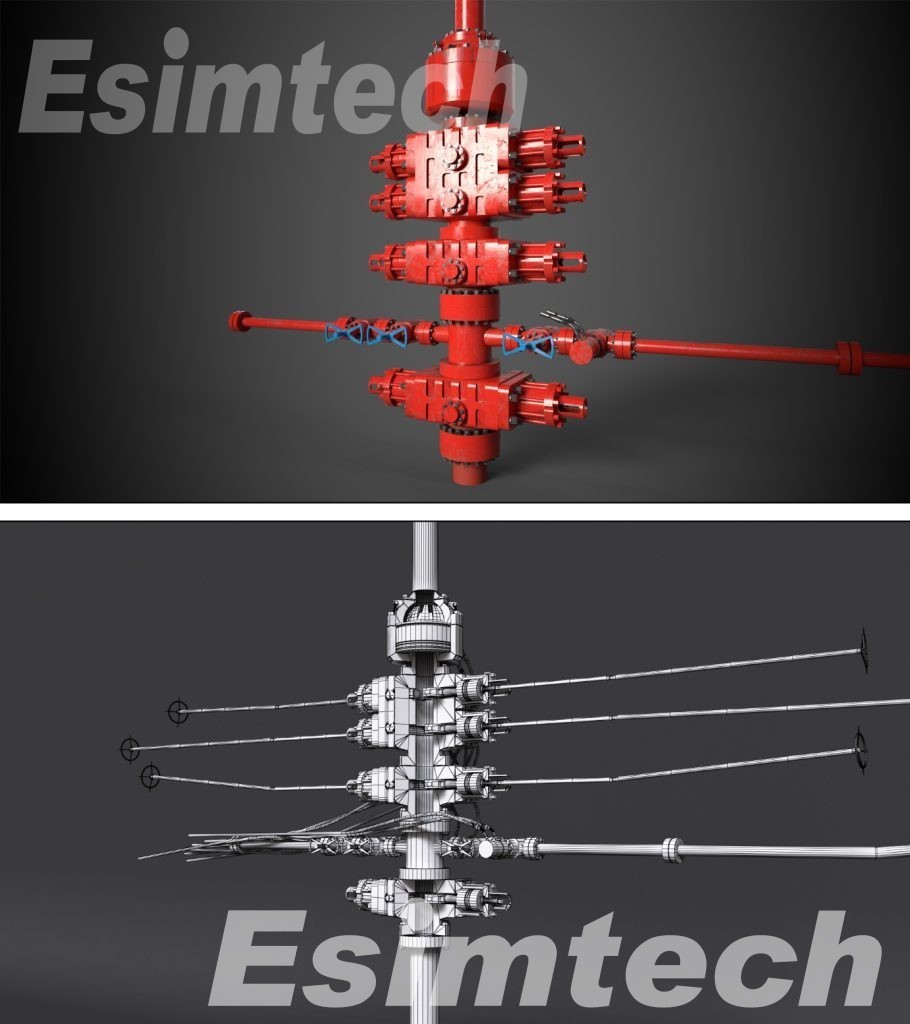

Blowout Prevention

A blowout is an uncontrolled release of oil and gas from a wellbore. Blowouts can be very dangerous, and they can also cause significant environmental damage.

One way that technology is being used to prevent blowouts is through the use of blowout preventers (BOPs). BOPs are a system of valves that can be used to close off the wellbore in the event of a blowout.

Another way that technology is being used to prevent blowouts is through the use of real-time monitoring systems. Real-time monitoring systems can monitor wellbore conditions and identify potential problems early on. This allows drillers to take corrective action to prevent a blowout from occurring.

Fire and Explosion Prevention

Drilling operations involve the use of flammable materials, and there is always the risk of fire and explosion.

One way that technology is being used to prevent fires and explosions is through the use of fire detection and suppression systems. Fire detection and suppression systems can detect fires early on and extinguish them before they cause significant damage.

Another way that technology is being used to prevent fires and explosions is through the use of real-time monitoring systems. Real-time monitoring systems can monitor drilling operations for potential hazards, such as gas leaks and electrical problems. This allows drillers to take corrective action before a fire or explosion can occur.

Emergency Exercise Simulation Technology Used in Improving Drilling Safety

Emergency exercise simulators are another important tool that is being used to improve drilling safety. Emergency exercise simulators can be used to create realistic simulations of drilling accidents, such as well control emergencies, H2S exposure, blowouts, and fires and explosions. This allows drillers to practice responding to these emergencies in a safe and controlled environment.

Emergency exercise simulators can also be used to train drillers on how to use new safety equipment and procedures. This training can help to ensure that drillers are prepared to respond to emergencies safely and effectively.

Here are some specific examples of how emergency exercise simulators are being used to improve drilling safety:

- Well control emergencies: Emergency exercises simulators can be used to train drillers on how to operate well control equipment and respond to well control emergencies. This training can help to ensure that drillers are prepared to handle well control emergencies safely and effectively.

- H2S exposure: Emergency exercises simulators can be used to train drillers on how to use personal protective equipment (PPE) and respond to H2S exposure. This training can help to reduce the risk of H2S poisoning.

- Blowouts: Emergency exercises simulators can be used to train drillers on how to respond to blowouts. This training can help to reduce the risk of injuries and fatalities.

- Fires and explosions: Emergency exercises simulators can be used to train drillers on how to respond to fires and explosions. This training can help to reduce the risk of injuries, fatalities, and property damage.

Overall, emergency exercises simulators are a valuable tool that can be used to improve drilling safety in a number of ways. By using emergency exercises simulators to train drillers on how to respond to emergencies and use new safety equipment and procedures, drilling companies can help to ensure the safety of their workers and the environment.

Conclusion

In general, the role of technology in improving drilling safety within the oil and gas industry is undeniably transformative. From automated well control systems to real-time monitoring and innovative H2S safety measures, these technological advancements not only enhance operational efficiency but also contribute significantly to the well-being of workers and environmental protection. As the industry continues to embrace and evolve with these technologies, the path forward involves a commitment to ongoing innovation, training, and simulation techniques, ensuring a safer and more sustainable future for drilling operations.