Understanding Well Control in the Petroleum Industry: A Comprehensive Overview

Well control is the practice of maintaining the hydrostatic pressure in a wellbore to prevent the uncontrolled flow of formation fluids. It is a critical aspect of oil and gas operations, as it helps to prevent blowouts, which are uncontrolled releases of oil and gas from a wellbore.

Blowouts can be extremely dangerous, causing serious oil rig injuries or death to workers, as well as damage to property and the environment. Well control helps to prevent blowouts by maintaining a balance between the hydrostatic pressure of the drilling fluid and the formation pressure.

Main Types of Well Control

Primary Well Control

Drilling Fluid (Mud) Weight: The primary method involves maintaining well control by using drilling mud, a specially formulated fluid that exerts hydrostatic pressure against the formation being drilled. The mud’s weight helps balance the pressure from the reservoir, preventing a blowout or loss of control.

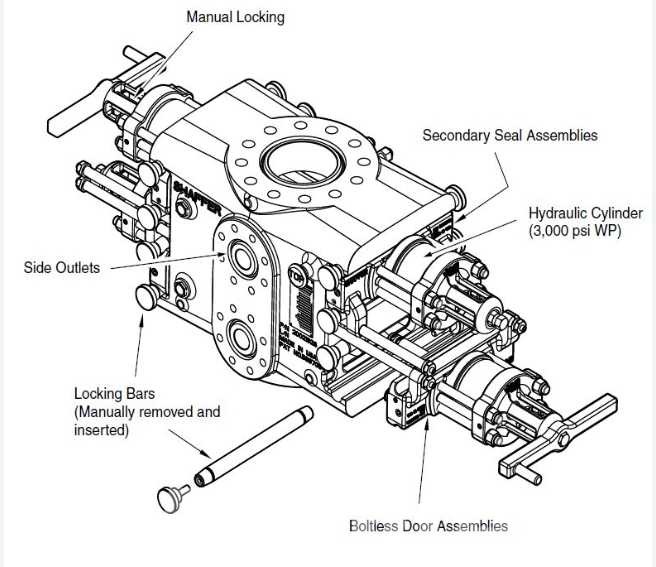

Blowout Preventers (BOPs): These are safety devices installed at the wellhead to control unexpected kicks (sudden influxes of formation fluids into the wellbore) and prevent blowouts. BOPs consist of various components like annular preventers, shear rams, and blind rams, which act as primary barriers in emergency situations.

Secondary Well Control

Kick Control Procedures: If primary control methods fail, secondary well control techniques are employed. These involve various measures to regain control after a kick has occurred. Techniques include shutting in the well, circulating out the influx of formation fluids, and well monitoring to ensure stability and safety.

Capping and Containment: Secondary control measures also encompass capping and containment methods. This involves sealing the well by installing specialized equipment, such as capping stacks, to control the flow or, in extreme cases, to completely shut in the well. Additionally, containment strategies are crucial for managing the flow of fluids from the well in the event of a blowout, enabling safe containment and recovery of any released hydrocarbons.

Equipment of Well Control

The following are some of the most common well control equipment:

- Blowout preventer (BOP): A BOP is a stack of valves and rams that can be used to seal the wellbore. It is the last line of defense against a blowout. BOPs are typically located at the top of the wellbore, but they can also be placed at other locations in the wellbore.

- Chokes: Chokes are valves that are used to restrict the flow of oil and gas from the wellbore. Chokes are typically used in conjunction with BOPs to provide additional control over the wellbore.

- Kill line: The kill line is a pipe that is used to pump kill fluid into the wellbore to increase the hydrostatic pressure and kill the well. Kill fluid is typically a heavy mud that is denser than the drilling fluid.

- Mud pumps: Mud pumps are used to circulate the drilling fluid through the wellbore. Mud pumps are essential for maintaining the hydrostatic pressure of the drilling fluid.

Procedures of Well Control

Well control procedures are a set of steps that are taken to prevent or control an influx of formation fluids into a wellbore. These procedures are essential for the safety of workers and the environment, as they help to prevent blowouts, which are uncontrolled releases of oil and gas from a wellbore.

There are a variety of well control procedures that can be used, depending on the specific situation. Some common well control procedures include:

- Kill weighting: This involves adding weight to the drilling fluid to increase its hydrostatic pressure. This helps to prevent formation fluids from entering the wellbore.

- Choking back: This involves restricting the flow of oil and gas from the wellbore. This can be done by closing the choke valve on the wellhead.

- Closing the BOP: The blowout preventer (BOP) is a stack of valves and rams that can be used to seal the wellbore. This is the last line of defense against a blowout.

In addition to these basic procedures, there are a number of advanced well control techniques that can be used in more complex situations. Some common advanced well control techniques include:

- Underbalanced drilling: This involves drilling a well with a hydrostatic pressure that is lower than the formation pressure. This is done to increase the rate of penetration and to improve the production of the well. However, it also requires careful well control planning and execution.

- Managed pressure drilling (MPD): This involves using a variety of techniques to control the pressure in the wellbore. MPD is typically used to drill wells with high formation pressures or to drill wells in sensitive environments.

- Dual gradient drilling (DGD): This involves using two different drilling fluids with different densities to control the pressure in the wellbore. DGD is typically used to drill wells with very high formation pressures.

Well Control Training

All oil and gas workers who work on wells must be trained in well control. Well control training typically includes instruction on the following topics:

- The principles of well control

- Well control equipment and procedures

- How to respond to well control emergencies

Well control training is essential for ensuring the safety of workers and the environment.

Well control training is crucial for worker and environmental safety. To enhance training effectiveness, the use of well control simulators is recommended. These simulators provide a realistic, risk-free environment for practicing well control responses, ensuring that oil and gas workers are well-prepared to handle emergencies with confidence

Conclusion

Well control is a complex and critical aspect of oil and gas operations. By understanding and using well control techniques, operators can help to prevent blowouts and other accidents. Well control is also important for protecting the environment and for protecting companies from financial losses.