Horizontal Drilling vs Directional Drilling: What’s the Difference & Which to Choose?

In the modern field of oil and gas exploration and development, “drilling a straight well” is no longer the only option, nor is it the most efficient one. As the exploration of oil and gas resources gradually moves towards deeper and unconventional areas, the limitations of ground conditions and the challenges in reservoir development have forced the drilling technology to constantly upgrade. Directional drilling and horizontal drilling, with their core capability of “precise directional control”, have become the two major core technologies supporting efficient oil and gas development. We will conduct a systematic analysis of directional drilling and horizontal drilling to help the engineering team better understand and select the appropriate drilling plan.

What is Directional Drilling Technology?

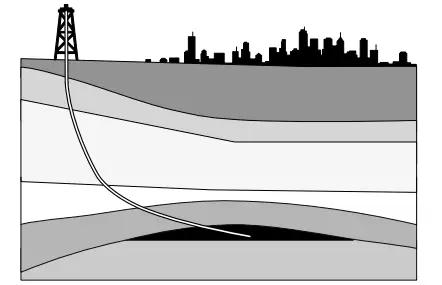

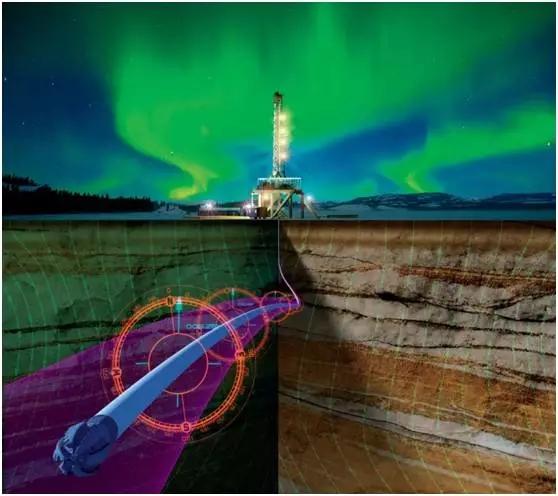

Directional drilling is a general term for a category of technologies, with the core being “flexible steering control“. By using steering tools, adjustable drilling equipment combinations, and measurement while drilling systems (MWD/LWD), engineers can obtain real-time data on the wellbore azimuth and inclination, and precisely adjust the drilling direction to avoid complex formations or accurately enter the target reservoir. In simple terms, directional drilling is “not drilling straight down”, but rather like a “curved tunnel”, following a pre-set trajectory, drilling diagonally and curving, and ultimately drilling the wellbore to the designated position of the target reservoir.

Directional drilling offers high trajectory flexibility, enabling it to avoid faults, collapse areas or other obstacles. It also supports centralized well placement at multiple wellheads, thereby enhancing the efficiency of well site utilization. Moreover, this technology can be used for drilling adjacent to existing wells, effectively tapping into the remaining oil and gas resources.

What is Horizontal Drilling Technology?

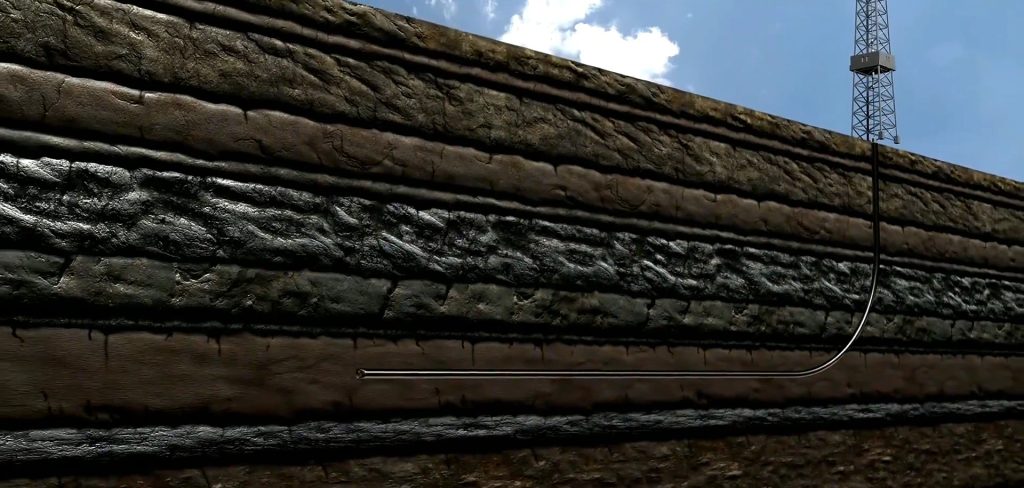

Horizontal drilling is a more advanced and specialized technology derived from directional drilling. Its drilling process can be divided into two steps: The first step is to drill vertically downwards until reaching above the target reservoir; the second step is to use specialized guiding tools to gradually “turn the wellbore”, until the wellbore approaches a horizontal position (with the well deviation angle close to 90°), and then “lie flat” and advance in the target reservoir, forming a continuous and long-distance horizontal section. It is like “first digging a vertical well, and then, underground in the oil and gas reservoir, horizontally dig a long corridor”, fully adhering to the reservoir, with the aim of maximizing the contact with oil and gas resources.

Its core feature is “precisely fitting the reservoir”, aiming to solve the problem of “whether efficient extraction can be achieved after drilling”, and it is particularly suitable for low-permeability reservoirs where oil and gas are difficult to flow.

Horizontal Drilling vs Directional Drilling: A Comparison of Core Technologies

From an engineering practice perspective, directional drilling and horizontal drilling differ significantly in many aspects.

1. Trajectory differences

Directional drilling: The trajectory is flexible. It can be drilled at an angle, in a curve, and the horizontal section can be short or even absent. It can only have an inclined section if it can reach the target point.

Horizontal drilling: The trajectory has strict requirements. There must be a long horizontal section (accounting for more than 60% of the total length), the inclination angle must be close to 90°, and the horizontal section must extend throughout the reservoir without deviating from the reservoir area.

2. Technical Difficulty

Directional Drilling: It mainly relies on conventional steering motors and on-the-well-measurement tools. A conventional drilling team can operate it after simple training. The drilling cost is similar to that of vertical wells, only with a little extra cost for the steering tools.

Horizontal Drilling: It requires a high-precision rotating steering system (RSS) and high-performance drilling fluid. The professional ability of the drilling team is extremely demanding. The cost is also 2-5 times that of directional wells – the main costs are concentrated on steering equipment, horizontal section drilling, and reservoir protection.

3. Core Objectives

The core objective of directional drilling is to “avoid obstacles and target the exact location“, addressing the issue of “whether it is possible to reach the target reservoir”.

The core objective of horizontal drilling is to “maximize contact with the reservoir”, addressing the issue of “whether efficient extraction can be achieved after reaching the reservoir“.

4. Applicable Reservoirs

Directional Drilling: Primarily suitable for medium-high permeability conventional reservoirs – these reservoirs have good oil and gas mobility. As long as the reservoir can be reached, effective exploitation can be achieved without the need for long horizontal sections to increase the contact area, such as conventional sandstone oil and gas reservoirs;

Horizontal Drilling: Primarily suitable for low-permeability unconventional reservoirs – these reservoirs have extremely poor oil and gas mobility. The production of vertical wells and conventional directional wells is extremely low, and even commercial development cannot be achieved. For example, shale oil, shale gas, tight sandstone gas, and coalbed methane, etc. Horizontal drilling combined with hydraulic fracturing is the only effective way to achieve commercial development for these reservoirs.

5. Output Benefits

Directional Drilling: The production is steadily increasing compared to conventional vertical wells, typically being 1-3 times that of vertical wells. The core advantage is “low cost and multiple targets”, which makes it highly cost-effective in conventional reservoirs and scenarios with limited access to the surface.

Horizontal Drilling: The production doubles or even multiplies that of vertical wells. In low-permeability reservoirs, the production is usually 10-50 times that of vertical wells. Although the single-well cost is high, the high production per well can quickly recover the cost, and after large-scale development, the comprehensive benefits are very significant, making it an indispensable technology in the development of unconventional oil and gas reservoirs.

Technology Selection Recommendations For Different Development Needs

When should directional drilling be chosen as the preferred method?

Directional drilling is a more reasonable choice when the target reservoir space is limited, the formation structure is complex, or obstacles need to be avoided. For example, in the centralized well placement on offshore platforms or in oil and gas development in urban areas, directional drilling can minimize the amount of ground engineering.

When is horizontal drilling more suitable?

If the development goal is to enhance recovery rate and single-well production, especially in unconventional oil and gas resources or low-permeability oil reservoirs, horizontal drilling usually offers greater economic advantages. Long horizontal sections can effectively expand the oil and gas flow channels and improve the overall development efficiency.

The Role of Simulation Technology in Drilling Operations

With the acceleration of the digitalization process in the oil and gas industry, simulation and data analysis technologies are playing an increasingly important role in directional and horizontal drilling. Through the drilling simulator, the well design can be optimized before the construction, and potential risks can be predicted.

At the same time, the simulation training system can help operators become familiar with complex working conditions in a virtual environment, improve their emergency handling capabilities, and reduce safety accidents caused by human errors. These technologies have become important safety guarantee measures in high-risk drilling operations.