Understanding Directional Drilling Training: Why It is Significant, What Are Key Components, and How Simulation Used in It

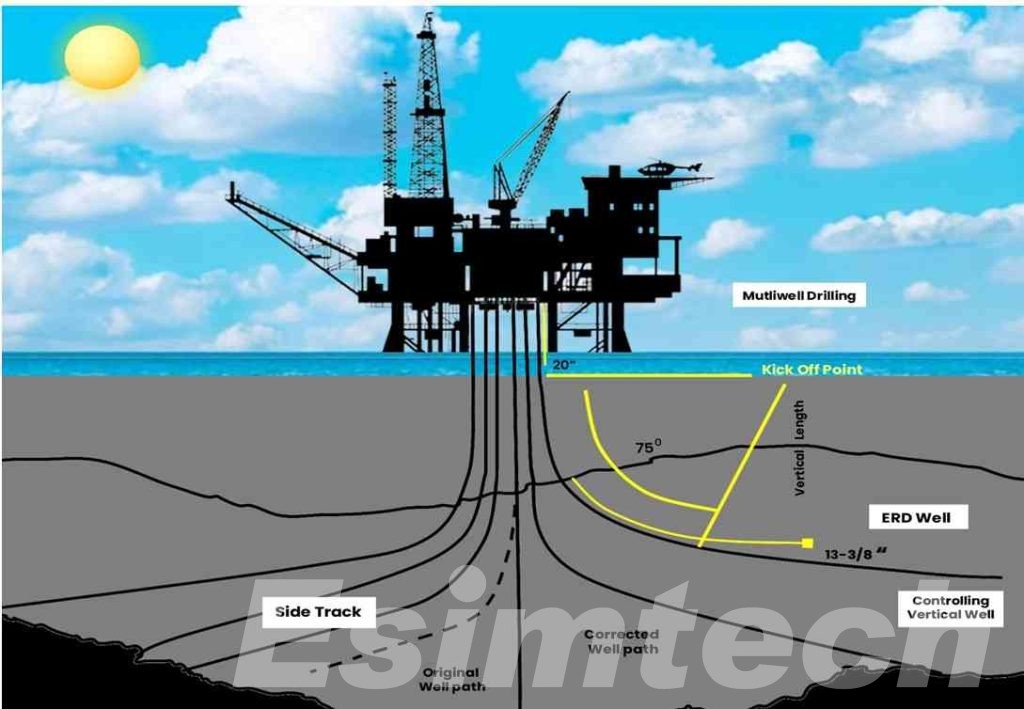

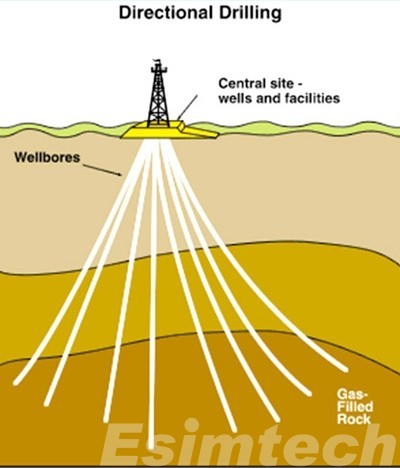

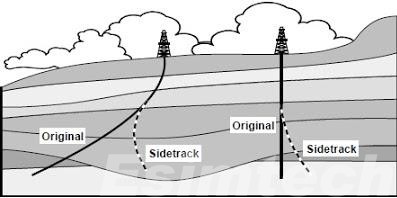

Directional drilling has transformed the oil and gas industry by allowing reserves to be reached beneath difficult geological formations. This advanced drilling technique allows operators to navigate wells in a controlled manner, allowing them to tap into reservoirs that were previously thought to be inaccessible. To be successful in directional drilling, professionals must receive specialized training that provides them with the necessary skills and knowledge. This article focuses on the topic of directional drilling training, exploring its significance, outlining the key components involved in mastering this complex technique and the simulation technology used in the directional drilling training.

The Importance of Directional Drilling Training

1. Technical Expertise

Directional drilling necessitates a thorough understanding of numerous technologies, equipment, and methodologies. Participants in training programs receive a solid foundation in the fundamentals of drilling engineering, geology, and surveying. This information is critical for making sound decisions during the drilling process.

2. Risk Mitigation

Because directional drilling is frequently performed in hazardous environments, the potential for risks and uncertainties is high. Training programs place a strong emphasis on safety protocols, risk assessment, and hazard management, ensuring that drillers can identify and address potential issues in order to avoid accidents and environmental damage.

3. Equipment Familiarity

Specialized equipment, such as downhole tools, mud motors, and rotary steerable systems, are required for directional drilling. Participants in training programs become acquainted with the operation, maintenance, and troubleshooting of these tools, allowing them to maximize drilling efficiency.

Key Components Involved in Directional Drilling Training

1. Theory and Fundamentals

Participants in directional drilling training begin with a thorough overview of drilling principles, such as the fundamentals of wellbore geometry, surveying techniques, and the use of mathematical models in the planning and execution of directional wells.

2. Surveying and Geosteering

Understanding the subsurface geology is essential for successful directional drilling. Training covers surveying methods, geostatistics, and geosteering technologies that allow drillers to navigate the wellbore in real time, ensuring precise positioning.

3. Drilling Software Proficiency

Directional drilling relies heavily on advanced oil and gas software applications for planning and monitoring. Training programs include hands-on experience with industry-standard software, enabling participants to create well plans, analyze data, and optimize drilling parameters.

4. Problem-Solving Skills

Professionals in directional drilling must be skilled at troubleshooting unexpected issues. Training programs emphasize problem-solving skills, preparing drillers to make quick decisions in dynamic drilling environments.

How Simulation Technology Used in Directional Drilling Training

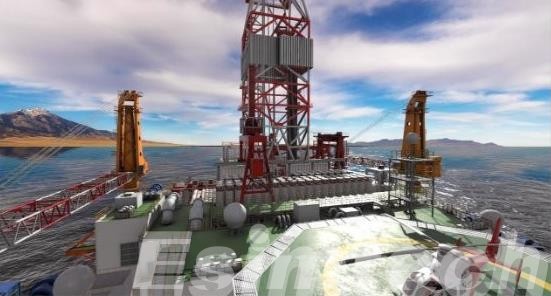

By providing a realistic and immersive learning environment, simulation technology plays a critical role in improving the effectiveness of directional drilling training. Simulation tools have become invaluable in training programs as the oil and gas industry continues to adopt cutting-edge technologies.

1. Virtual Reality (VR) and Augmented Reality (AR)

Immersive Learning Environments: VR and AR technologies create immersive 3D environments that mimic real-world drilling scenarios. Trainees can use virtual reality headsets or augmented reality devices to experience a simulated drilling rig, downhole conditions, and the surrounding environment.

Hands-On Experience: These technologies enable trainees to interact with virtual equipment and tools, enhancing their understanding of the drilling process. They can practice tasks such as well planning, tool handling, and emergency response in a risk-free virtual space.

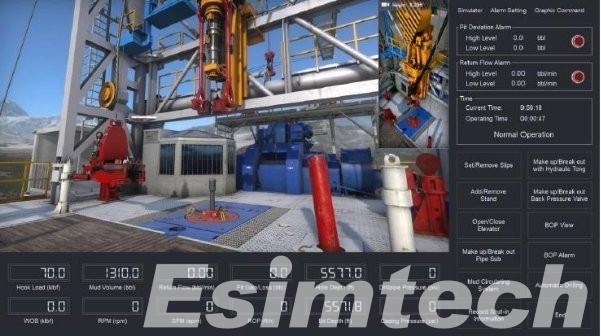

2. Drilling Simulators

Realistic Rig Operation: Drilling simulators simulate the operation of a drilling rig, giving trainees a realistic experience with drilling procedures. Simulators include controls, displays, and feedback systems that are similar to those found on a real-world rig, allowing trainees to practice their skills in a safe environment.

Dynamic Scenarios: Simulators can simulate a variety of drilling conditions, such as different geological formations, equipment malfunctions, and environmental challenges. This allows trainees to practice problem-solving skills and learn how to respond to changing circumstances.

3. Software-Based Simulations

Planning and Analysis: Directional drilling necessitates extensive planning and analysis. Using industry-standard software tools, software-based simulations enable trainees to create well plans, analyze geological data, and optimize drilling parameters. This practical training prepares them for real-world challenges.

Data Interpretation: Trainees can practice interpreting survey data, geosteer wells, and make decisions based on real-time information. Simulations provide a platform for refining data interpretation skills, crucial for precise wellbore navigation.

4. Downhole Tool Simulations

Tool Handling and Operation: Downhole tool simulations, such as mud motors and rotary steerable systems, allow trainees to practice their operation and understand how they affect directional drilling. This includes figuring out how to troubleshoot common problems and optimize tool performance.

Maintenance Training: Simulations provide a safe environment for trainees to learn about downhole tool maintenance and repair. This hands-on experience enhances their familiarity with equipment and ensures they can address issues efficiently.

5. Field Exercises and Team Collaboration

Team-Based Simulations: Directional drilling often involves collaboration among team members. Simulation technology allows trainees to engage in collaborative exercises, where they can work together to solve problems, make decisions, and communicate effectively, fostering teamwork skills.

Field Training Simulations: Simulations can replicate field conditions, allowing trainees to practice directional drilling in diverse environments. These simulations may include challenging terrains, unexpected geological features, and adverse weather conditions.

Conclusion

The development of skilled professionals in the oil and gas industry relies heavily on directional drilling training. As the demand for energy resources grows, the ability to efficiently extract hydrocarbons from complex reservoirs becomes increasingly important. Incorporating simulation technology into directional drilling training programs not only improves the learning experience, but it also provides trainees with a safe and controlled environment in which to develop and refine their skills.