What are Technological Advances in Drilling Techniques in the Oil and Gas Industry and How is Simulation Used in Them

Technological advancements have played a critical role in increasing drilling efficiency, safety, and environmental sustainability. This article investigates the cutting-edge technologies that are revolutionizing drilling techniques in the oil and gas industry, as well as the use of simulation technology in drilling techniques.

Key Technological Advances of Drilling Techniques in the Oil and Gas Industry

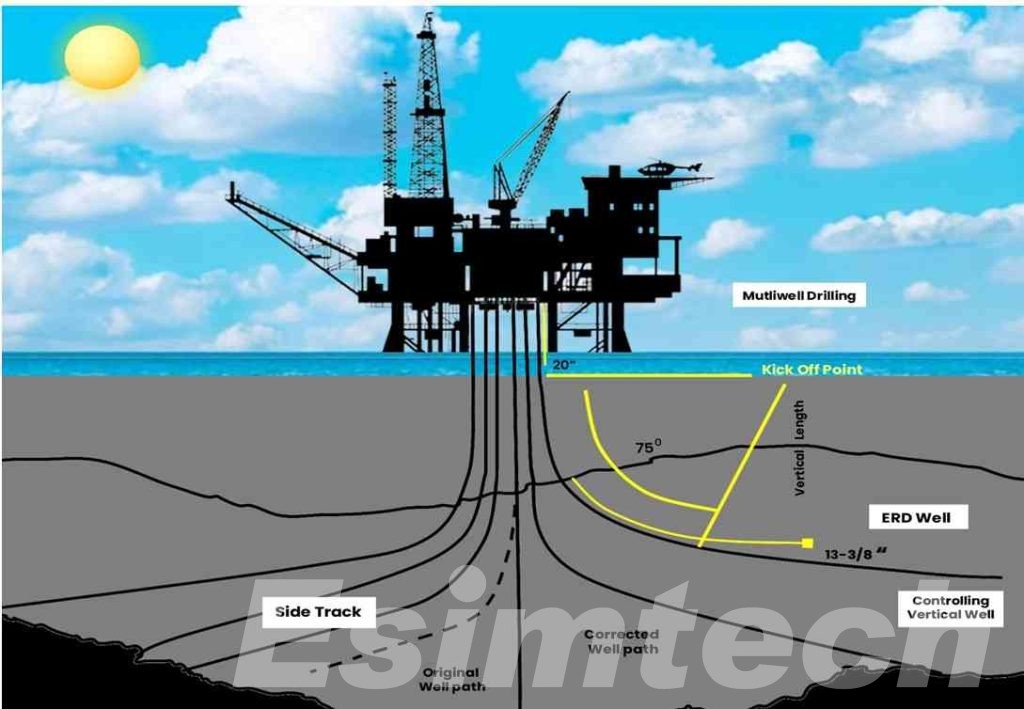

1. Directional Drilling and Extended Reach Technologies

Overview

Directional drilling has advanced significantly, allowing operators to access and extract hydrocarbons from reservoirs that were previously considered difficult or uneconomical. Drilling wells with horizontal or highly deviated sections, maximizing reservoir exposure, is a subset of directional drilling.

Benefits

Increased Reservoir Contact: Operators can use extended reach drilling to intersect multiple layers of a reservoir, increasing contact area and increasing production rates.

Reduced Environmental Impact: By accessing multiple reservoir layers from a single well, the need for additional wells and surface infrastructure is minimized, leading to a smaller environmental footprint.

2. Managed Pressure Drilling (MPD)

Overview

Managed Pressure Drilling is a technology that allows for precise control of wellbore pressure, resulting in increased drilling efficiency and safety. MPD systems actively manage wellbore pressure by adjusting drilling fluid density in real time, thereby preventing kicks and preserving well integrity.

Benefits

Improved Safety: MPD improves well control by reducing the risk of blowouts and kicks, lowering the risk of accidents, and increasing overall operational safety.

Increased Drilling Efficiency: The ability to optimize drilling parameters in real-time increases drilling speed and efficiency, which leads to cost savings.

3. Automated Drilling Systems

Overview

With the introduction of Automated Drilling Systems (ADS), automation has made its way into drilling operations. These systems use advanced algorithms, sensors, and control systems to adjust drilling parameters autonomously, improving accuracy and efficiency.

Benefits

Enhanced Precision: Automation reduces human error and enables precise control of drilling parameters, resulting in more precise wellbore placement.

Increased Efficiency: Continuous operation of automated drilling systems optimizes drilling processes and reduces downtime.

4. Drilling with Electromagnetic Imaging

Overview

Innovations in electromagnetic imaging technologies have transformed the way operators visualize subsurface formations during drilling. Electromagnetic sensors and imaging tools provide real-time data on the geological composition of the formation, aiding in decision-making during drilling operations.

Benefits

Improved Formation Evaluation: Electromagnetic imaging allows for better characterization of subsurface formations, enabling operators to make informed decisions regarding well placement and production potential.

Reduced Drilling Risks: Enhanced understanding of subsurface geology helps mitigate drilling risks, such as encountering unexpected formations or hazards.

5. Drilling with Advanced Materials and Bits

Overview

Advancements in materials science have led to the development of high-performance drill bits made from advanced materials like polycrystalline diamond compact (PDC) and diamond-impregnated bits. These bits exhibit improved durability and cutting efficiency, especially in challenging drilling environments.

Benefits

Extended Bit Life: Advanced materials enhance the wear resistance of drill bits, resulting in longer bit life and reduced downtime for bit replacements.

Higher Drilling Rates: Improved cutting efficiency of advanced drill bits allows for higher drilling rates, contributing to faster and more cost-effective well construction.

How Simulation Technology Used for Drilling Techniques in the Oil and Gas Industry

In the oil and gas industry, simulation is especially important in the realm of drilling techniques. Drilling and well control simulations are sophisticated computer-based models that simulate real-world drilling scenarios, providing valuable insights into wellbore behavior, interaction with subsurface formations, and the overall drilling process.

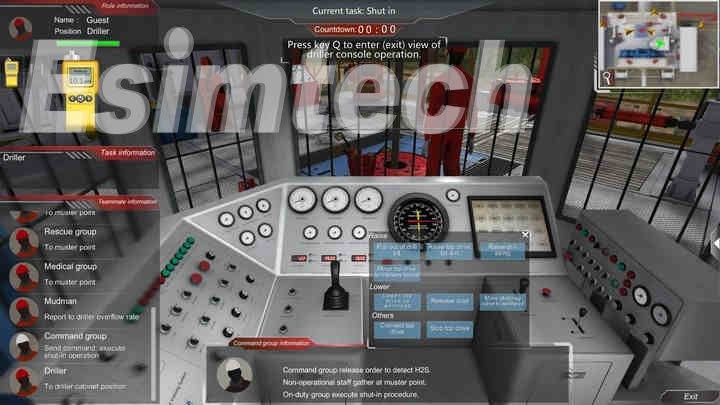

1. Training and Skill Development

Objective

Drillers and engineers can improve their expertise in a risk-free virtual environment before engaging in actual drilling operations by using simulation for training and skill development.

Benefits

Realistic Scenarios: Simulations recreate real-world drilling challenges, providing drillers with a realistic training environment in which to hone their skills and decision-making abilities.

Safety Training: Simulations help drillers and personnel practice emergency response procedures, enhancing their preparedness for unexpected events during actual drilling operations.

2. Wellbore Stability Analysis

Objective

Simulations are utilized to assess wellbore stability by modeling the interactions between the drilling fluid, the wellbore, and the surrounding formations. This analysis helps prevent issues such as well collapse or formation damage.

Benefits

Risk Mitigation: By simulating different drilling scenarios, engineers can identify potential wellbore stability issues and implement mitigation strategies, reducing the risk of costly drilling problems.

Optimization: Simulation allows for the optimization of drilling fluid properties and wellbore design, ensuring stable and efficient drilling operations.

- Managed Pressure Drilling (MPD) Optimization

Objective

Simulation tools are used to optimize managed pressure drilling (MPD) operations. By modeling wellbore pressure dynamics, simulations help determine the optimal drilling parameters for maintaining pressure within a safe and efficient range.

Benefits

Efficiency Improvement: Simulations assist in finding the ideal combination of drilling fluid properties, choke settings, and other variables to maximize drilling efficiency and well control.

Real-time Decision Support: Some simulations can operate in real-time, providing continuous decision support to drilling teams during MPD operations.

4. Hydraulic Fracturing Simulations

Objective

Hydraulic fracturing processes are modeled using simulation to help engineers understand how fractures propagate in the reservoir and how different parameters affect fracture growth.

Benefits

Optimizing Fracture Design: Simulations aid in the design of hydraulic fracturing treatments by taking into account variables such as fluid viscosity, proppant concentration, and well spacing.

Predicting Reservoir Response: Engineers use simulations to predict how fractures will interact with the reservoir, assisting with reservoir management and forecasting production.

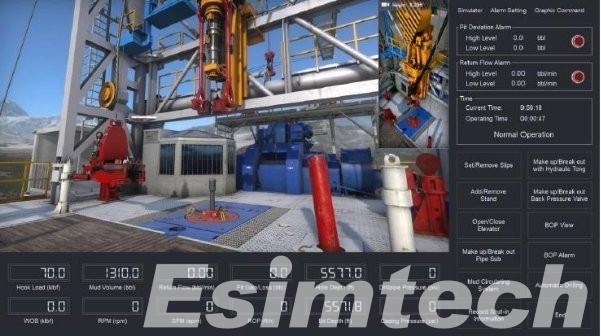

5. Real-time Drilling Decision Support

Objective

During drilling operations, real-time drilling simulations provide continuous decision support. These simulations combine real-time rig data with the model, allowing engineers to make informed decisions on the fly.

Benefits

Immediate Response: Real-time simulations enable rapid response to unexpected events, reducing risks and optimizing drilling processes as conditions change.

Continuous Improvement: Data from real-time simulations contribute to continuous improvement by providing insights into drilling performance and suggesting adjustments for future operations.

Conclusion

Technological advances in drilling techniques are reshaping the oil and gas industry landscape, providing unprecedented opportunities for increased efficiency, safety, and environmental responsibility. As technology advances, the industry can expect even more sophisticated technologies that push the limits of what is possible in oil and gas exploration. These advancements not only help the industry compete, but they also play an important role in ensuring a sustainable and responsible approach to meeting the world’s energy needs.

Modern drilling techniques in the oil and gas industry rely heavily on simulation. Simulation tools enable drilling teams to optimize operations, improve safety, and mitigate risks by leveraging sophisticated models and real-time data integration.