5 Key Points to Know What are Drilling Systems in the Oil and Gas Industry

In the vast expanse of the oil and gas industry, the exploration and extraction of hydrocarbons from beneath the Earth’s surface require a sophisticated symphony of engineering marvels. At the heart of this intricate choreography lies the drilling system, a complex ensemble of technologies, equipment, and methodologies that pierces through layers of rock and sediment to unlock the world’s energy resources. In this article, we embark on a journey to uncover the cutting-edge drilling systems propelling the oil and gas industry into a new era of efficiency, safety, and resource optimization.

The Essence of Drilling Systems

As the heart of the oil and gas industry, drilling systems pulsate as the vital lifeline, facilitating the exploration and extraction of Earth’s hidden treasures. These intricate systems amalgamate cutting-edge technologies, machinery, and expertise to delve into the depths of the subsurface, unraveling the coveted hydrocarbon reservoirs.

Drilling systems orchestrate the synchronized dance of drill bits, drill strings, hoisting mechanisms, and mud circulation, culminating in the creation of wellbores. This intricate choreography not only unlocks access to precious resources but also embodies precision, innovation, and relentless determination. Through the interplay of components like well control equipment, casing, and logging tools, drilling systems ensure the integrity of operations, guarding against potential hazards while harnessing the power of modern engineering.

As the industry evolves, drilling systems remain the backbone of oil and gas endeavors, embodying the relentless pursuit of energy excellence while reshaping the world’s energy landscape.

The Core Components of Drilling Systems

The core components of drilling systems form the intricate web of technologies and equipment essential for the successful exploration and extraction of oil and gas resources. These components collaborate seamlessly to drive the drilling process forward, ensuring efficiency, safety, and optimal wellbore creation.

- Drill Bit: The drill bit is the point of contact between the rig and the Earth’s crust. Advanced drill bit designs, such as polycrystalline diamond compact (PDC) and roller cone bits, are engineered to cut through various rock formations with precision.

- Drill String: Comprising the drill pipe, drill collars, and other accessories, the drill string provides the conduit for transmitting power and torque from the rig to the drill bit.

- Mud Circulation System: This system involves drilling fluid, or “mud,” which lubricates the drill bit, cools the drill string, and carries cuttings to the surface. Mud also provides crucial pressure control to prevent blowouts.

- Hoisting System: The hoisting system uses the drawworks to raise and lower the drill string, enabling vertical movement within the wellbore.

- Rotating System: The rotating system powers the rotation of the drill string and bit, allowing for efficient drilling of the wellbore.

Together, these core components harmonize their functions, orchestrating a symphony of engineering prowess that characterizes drilling systems in the oil and gas industry.

Benefits and Impact of Drilling Systems

- Efficiency Enhancement: Modern drilling systems optimize drilling speed, reduce non-productive time, and minimize downtime, contributing to more efficient operations.

- Safety Advancements: Drilling systems incorporate state-of-the-art safety features, real-time monitoring, and automated controls to enhance personnel safety and prevent accidents.

- Resource Optimization: By maximizing the utilization of equipment and minimizing operational inefficiencies, drilling systems contribute to cost savings and resource optimization.

- Environmental Considerations: Advanced drilling technologies aim to minimize environmental impact through reduced emissions, efficient mud management, and optimized wellbore integrity.

Simulation of Drilling Systems

In the dynamic realm of oil and gas exploration, the quest for efficiency, safety, and precision has spurred the evolution of drilling systems. At the forefront of this transformation lies simulation technology, an innovative approach that empowers the industry to test, optimize, and revolutionize drilling operations in virtual environments. Drilling systems simulations bring together the intricacies of engineering, data analysis, and real-world scenarios to create a digital playground for engineers, operators, and decision-makers.

In order to show the real oil drilling production site and cultivate students’ relevant knowledge and skills, Esimtech has established a drilling and well control simulation system, which fully reproduces the scene and working atmosphere of oil drilling work. Through this simulation technology, you can fully understand the drilling system and master its application knowledge.

Innovations and Transforming in Drilling Systems

In the ever-evolving landscape of the oil and gas industry, innovation serves as the driving force behind the transformation of drilling systems. Pioneering technologies are reshaping conventional practices, enhancing efficiency, safety, and environmental responsibility. These innovations are not only propelling the industry forward but also redefining its capabilities and potential.

- Automated Drilling: Automation has revolutionized drilling operations, enabling real-time monitoring, data analysis, and decision-making. Automated drilling systems utilize sensors and advanced algorithms to optimize drilling parameters, detect anomalies, and adjust operations in response to changing downhole conditions.

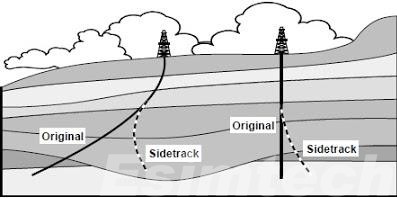

- Directional Drilling: Advanced directional drilling techniques, such as rotary steerable systems and electromagnetic guidance, enable precise wellbore placement and access to previously inaccessible reservoirs, maximizing resource recovery and reservoir drainage.

- Managed Pressure Drilling (MPD): MPD techniques control wellbore pressure to prevent kicks and losses, enhancing safety and efficiency. By optimizing pressure, MPD enables drilling through challenging formations while minimizing formation damage.

- Dual Gradient Drilling: This technique uses two different types of drilling fluid to balance wellbore pressures, making drilling in challenging environments, such as deepwater, more manageable.

- Casing While Drilling (CWD): CWD systems allow operators to simultaneously drill and install casing, saving time and reducing the risk of wellbore instability.

These innovations are ushering in a new era of drilling systems, where precision, automation, and sustainability converge to unlock previously untapped potential in the oil and gas industry. As technology continues to advance, the industry is poised to reach greater depths, access more challenging reservoirs, and conduct operations with unprecedented efficiency and environmental responsibility.

Conclusion

Drilling systems represent the dynamic heart of the oil and gas industry, combining cutting-edge technology, engineering prowess, and operational expertise to unlock vital energy resources.

Simulation-driven drilling systems have emerged as a game-changing force in the oil and gas industry, offering a virtual canvas for exploration and innovation. By harnessing the power of simulations, the industry can optimize drilling operations, enhance decision-making, and pioneer new techniques in a risk-free environment. As this technology continues to evolve, the realm of drilling systems simulation promises to usher in a new era of efficiency, safety, and sustainability, shaping the future of oil and gas exploration and production.