Working on an Offshore Oil Rig: What are Main Risks and What are Commonly Used Safety Measures

Offshore oil rig employment offers a unique combination of financial rewards and a distinctive working environment. However, it is also a profession accompanied by inherent risks due to the remote and challenging nature of the job. In this comprehensive article, we’ll delve deeply into the multifaceted risks associated with offshore oil rig employment and the strategies in place to manage and mitigate these challenges.

Main Risks of Working on an Offshore Oil Rig

1. Environmental Challenges:

One of the most evident and formidable challenges in offshore oil rig work is the often unforgiving natural environment. These rigs are typically situated far from the shore, placing workers in remote and often harsh locations. Here are some of the environmental challenges:

- Unpredictable Weather: Offshore rigs are exposed to unpredictable weather patterns, including high winds, rough seas, and extreme temperatures. Storms and hurricanes can disrupt operations and pose a significant risk to personnel.

- Slippery Surfaces: Weather conditions can lead to slippery surfaces, increasing the risk of falls and injuries.

- Fall Overboard Risk: The potential for falling overboard due to challenging sea conditions underscores the importance of adhering to strict safety protocols and wearing personal protective equipment.

2. Health and Safety Hazards:

Offshore drilling and production involve intricate machinery, high-pressure systems, and the handling of flammable materials, posing a variety of health and safety risks:

- Physical Hazards: Workers may face physical hazards such as slips, trips, and falls. In some cases, more severe threats such as oil explosions, fires, and chemical exposure are possible.

- Safety Protocols: Rig employees are thoroughly trained to follow strict safety protocols, including the use of personal protective equipment, to mitigate these risks.

3. Emergency Situations:

Offshore oil rigs are equipped with safety equipment and emergency response plans to address contingencies:

- Isolation Challenges: The remote nature of these platforms can create challenges for emergency services to respond promptly in case of a fire, gas leak, or other critical incidents. Rig workers must be well-versed in emergency procedures, including evacuation protocols and the use of safety equipment like lifeboats and personal flotation devices.

4. Limited Medical Facilities:

Offshore oil rigs typically have medical facilities with trained personnel to handle common injuries and medical issues:

- Severe Injuries: In cases of severe injuries or illnesses, the distance from comprehensive medical care can be a significant concern. Remote locations can hinder timely access to advanced medical facilities, potentially impacting the outcome of a serious medical emergency.

5. Transportation Risks:

Transporting workers to and from offshore platforms via helicopters or boats carries its own set of risks:

- Helicopter and Boat Risks: These include potential accidents during take-off and landing, as well as challenges posed by rough seas. Rig workers undergo specialized training to minimize these risks.

Working on an offshore oil rig is indeed a high-risk occupation, but the industry prioritizes safety. Rig operators, employers, and regulatory bodies invest significantly in training, technology, and safety measures to reduce risks and ensure the well-being of their workers. While the risks are real, a combination of vigilance, robust safety measures, and thorough training can help mitigate these hazards and make offshore oil rig work safer.

Safety Measures for Working on an Offshore Oil Rig

Working on an offshore oil rig is a high-risk occupation, and safety is of paramount importance to protect the lives of workers and the environment. Common safety measures for working on an offshore oil rig include:

Personal Protective Equipment (PPE):

- Hard hats to protect from falling objects.

- Safety glasses to shield the eyes from debris and chemicals.

- Ear protection for noise control.

- Flame-resistant clothing to prevent burns.

- Steel-toed boots to protect feet.

Fall Prevention:

- Guardrails and handrails to prevent falls.

- Safety nets for working at heights.

- Fall arrest systems, including harnesses and lanyards.

Emergency Response Plans:

- Well-defined plans for various emergencies, such as fire, oil spills, and medical incidents.

- Regular drills and training for all personnel to ensure they know how to respond.

Fire Safety:

- Fire-resistant materials and coatings on structures.

- Regular inspection and maintenance of firefighting equipment.

- Fire drills to practice emergency response.

Confined Space Entry:

- Strict protocols for entering confined spaces, including gas testing and ventilation.

- Proper training for workers involved in confined space entry.

Hazardous Materials Handling:

- Proper storage and labeling of hazardous materials.

- PPE use and training for handling chemicals and drilling fluids.

Safe Lifting and Handling:

- Training on proper lifting techniques to prevent strain injuries.

- Well-maintained cranes and hoisting equipment.

Tool and Equipment Safety:

- Regular maintenance and inspection of tools and equipment.

- Proper usage and storage procedures.

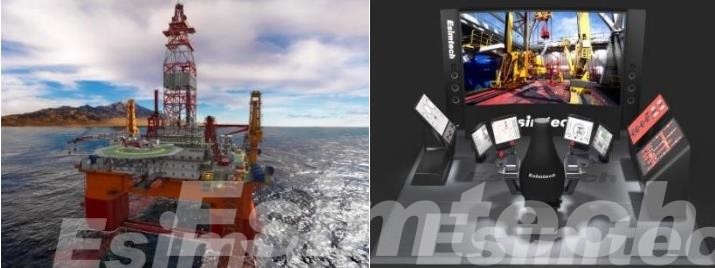

Simulation Technology Used for Working on an Offshore Oil Rig

Simulation technology is integral to offshore oil rig operations, offering a wide range of benefits. It is a vital tool for training and skill development, allowing workers to practice in a controlled environment and hone their abilities without exposure to real risks. Simulators are especially beneficial for emergency response training, enhancing safety measures and mitigating potential risks.

Beyond safety, simulation technology improves operational efficiency by providing hands-on experience with complex equipment and procedures, reducing downtime and resource wastage. It also plays a significant role in environmental protection, with oil spill response training and environmental monitoring simulations. Furthermore, it aids in cost reduction, supports technology integration, enables research and development, facilitates risk assessment, and provides operational flexibility for offshore oil rig works.

Conclusion

In conclusion, working on an offshore oil rig is undeniably risky. However, rigorous safety measures and a commitment to continuous improvement are in place to mitigate these risks and ensure the well-being of the workers and the environment. The oil industry recognizes the challenges associated with offshore work and is dedicated to creating a safer and more sustainable future for its workforce.