What are the Portable Workover Simulators: Key Components and Key Functionality

Workover operations involving interventions on oil and gas wells necessitate highly qualified staff and rigorous planning to assure productivity and safety. Portable workover simulators are small, mobile devices that bring the advantages of workover simulation to the field. These simulators make use of cutting-edge software, hardware, and virtual reality technologies to provide a realistic and immersive training environment that can be put anywhere workover operations are carried out. Let us look more closely at the components and functionality of the portable workover simulator.

What are the Key Components of Portable Workover Simulators

Portable workover simulators are made up of numerous critical components that allow them to function and provide a realistic training experience.

Portable Computer or Laptop

A portable workover simulator’s main hardware component is a high-performance PC or laptop. It should have a powerful processor, sufficient memory, and a dedicated graphics card capable of rendering complex simulations. The portable nature of the computer allows it to be easily transported and set up at the workover site.

Virtual Reality (VR) or Augmented Reality (AR) Devices

To improve the user experience, many workover simulations combine VR or AR technologies. Headsets, goggles, or glasses that deliver immersive images and a sense of presence within the virtual environment are examples of such equipment. They may also contain hand controllers or other input devices that let users to engage with and conduct tasks on the simulated equipment.

Haptic Feedback Devices

Haptic feedback devices are peripherals that provide the user with tactile sensations, increasing the realism of the simulation. By providing vibrations or forces to the user’s hands or other body parts, these gadgets can replicate the feeling of touch. When working with virtual tools or equipment, for example, haptic feedback devices can provide resistance or feedback, simulating the physical sensations felt during genuine workover procedures.

Simulation Software

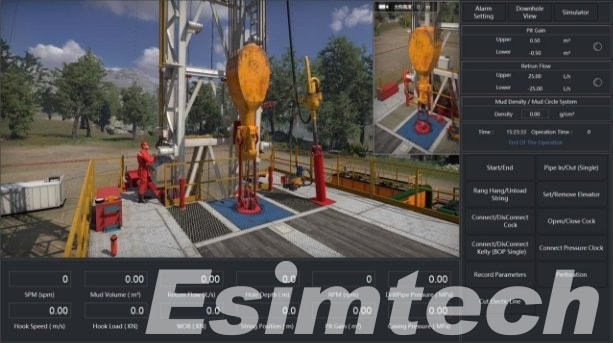

The simulation software is a critical component of portable workover simulators. It is responsible for creating the virtual environment, simulating the physics and mechanics of workover operations, and providing the interactive experience. The software generates realistic graphics, models the behavior of fluids and equipment, and incorporates real-world data to accurately represent the well conditions and associated challenges.

Data Integration and Analysis

Portable workover simulators rely heavily on simulation software. It is in charge of generating the virtual world, simulating the physics and mechanics of workover activities, and delivering the interactive experience. To effectively reflect the well conditions and associated obstacles, the software provides realistic images, models the behavior of fluids and equipment, and combines real-world data.

User Interface and Controls

Real-time data streams from the field can be integrated into workover simulators to enhance the simulation experience and provide useful insights. Data such as well parameters, production data, or equipment performance data might be included. The simulator can dynamically change the simulation based on changing conditions and offer operators with feedback and analysis of their actions and decisions by incorporating real-time data.

What are the Key Functionality of Portable Workover Simulators

Realistic Workover Environment

Portable workover simulators are devices that simulate the physical environment encountered during workover procedures. They reproduce the wellbore, downhole equipment, and geology surrounding the workover site, creating a visually accurate picture of the workover site. This reality allows employees to become acquainted with the precise situations they will face and improves their comprehension of the operating setting.

Interactive Training

Portable workover simulators allow workers to actively participate in simulated workover procedures, facilitating interactive training sessions. Within the simulator, users can control virtual tools and equipment, conduct tasks, and engage in various workover operations. This hands-on approach assists workers in developing skills, improving decision-making abilities, and developing confidence in their abilities.

Scenario Customization

Portable workover simulators allow scenarios to be tailored to individual well conditions and operating requirements. Operators can enter site-specific data, such as well parameters, production history, and equipment specifications, to build virtual well models that are nearly identical to the actual workover site. This personalization allows personnel to learn and plan in an environment that closely matches the specific characteristics of each well.

Real-Time Feedback and Assessment

Portable workover simulators offer real-time feedback and evaluation of user actions and performance. The simulator monitors and assesses the user’s interactions and decisions, providing rapid feedback on technique, timing, and compliance with safety rules. Workers can learn from their failures, adjust their techniques, and increase their overall competency in workover operations thanks to this real-time assessment.

Planning and Optimization

Portable workover simulators provide real-time workover planning and optimization. The simulator allows operators to try different workover tactics, identify potential risks, and adjust their plans for increased efficiency. The simulator provides a platform for operators to experiment with different situations and evaluate the potential consequences, allowing them to optimize their workover operations and reduce operational risks.

Safety Protocol Training

In workover operations, safety is crucial, and portable simulators help to improve safety training. They provide a controlled environment in which personnel can practice safety protocols, emergency procedures, and important safety skills related to workover tasks. Workers can learn the essential abilities and reflexes to respond effectively in real-life scenarios by modeling potential hazards and emergency situations.

Summary

The introduction of portable workover simulators is a watershed moment in the oil and gas industry, altering the way workover operations are carried out.