What are the Types of Well Stimulation Technologies

Keeping oil and gas wells flowing at optimal rates is important for maximizing production. However, over time, natural rock formations can become clogged or less permeable, hindering the flow of hydrocarbons. This is where well stimulation technologies come in. These techniques enhance a well’s ability to produce by increasing the permeability of the reservoir rock, allowing oil and gas to flow more freely to the surface.

Main Types of Well Stimulation Technologies

There are three primary methods for well stimulation, each suited to address specific formation challenges:

Hydraulic Fracturing (Fracking)

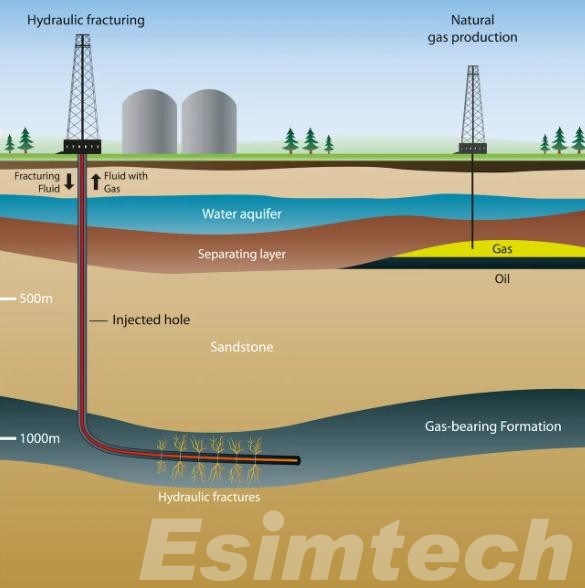

Fracking is the most widely used well stimulation technique, particularly for low-permeability rock formations like shale. It involves injecting a high-pressure fluid (fracturing fluid) mixed with proppant (sand-like particles) into the wellbore. The fracturing fluid, typically a water-based solution with additives, creates fractures in the rock formation by overcoming the rock’s natural pressure. Proppant, usually ceramic or sand, keeps these fractures open after the pressure is released, creating a permanent pathway for oil and gas to flow more easily towards the wellbore.

Fracking allows for the production of hydrocarbons from formations previously deemed uneconomical due to low permeability. It significantly increases well productivity and extends the productive life of mature wells.

However, fracking can be a complex and controversial process. Environmental concerns regarding water usage and potential contamination of groundwater supplies exist. Additionally, seismic activity linked to fracking operations has raised public safety issues. Technological advancements are continuously being made to address these concerns, with a focus on using less water and more environmentally friendly fracturing fluids.

Acidizing

This method utilizes various acids to dissolve formation damage caused by mineral deposits, scale buildup, or drilling mud residue. The specific type of acid used depends on the type of formation damage being targeted. For example, hydrochloric acid (HCl) is commonly used for dissolving carbonate minerals like limestone and dolomite, while hydrofluoric acid (HF) is used for dissolving silica-based scale. The acid is carefully injected into the formation through the wellbore, where it reacts with the targeted minerals, dissolving them and creating enlarged channels within the rock for improved oil and gas flow.

It is a well-established technique commonly used in carbonate reservoirs (limestone and dolomite) where formation damage from carbonate scale buildup is a significant concern. It can also be applied in sandstone formations with specific acid formulations tailored to dissolve damaging minerals like clays or iron oxides.

Considerations: The selection of the appropriate acid and its concentration is crucial to ensure effective treatment while minimizing damage to the formation itself. Additionally, proper disposal of spent acid and dissolved minerals is essential to comply with environmental regulations.

Other Well Stimulation Methods

Beyond fracking and acidizing, several other stimulation techniques exist for specialized applications:

- Matrix Acidizing: This is a variation of acidizing suitable for formations with widespread, rather than localized, damage. It involves injecting smaller volumes of a weaker acid directly into the rock matrix surrounding the wellbore. This creates a network of microscopic channels within the rock, enhancing overall permeability near the wellbore and improving oil and gas flow.

- Nitrogen Lift: This method utilizes pressurized nitrogen gas injected into the wellbore to remove debris, lighten wellbore fluids, and improve well productivity. Nitrogen gas, being much lighter than formation fluids, helps to lift fluids and enhance well flow, particularly in wells with low reservoir pressure or high fluid viscosity.

- Jetting: High-pressure jets of water or abrasive fluids can be used to clean perforations or remove near-wellbore formation damage. This technique is particularly effective for removing drilling mud residue or formation debris that can clog perforations and restrict flow.

Choosing the Right Well Stimulation Method

Selecting the most effective well stimulation technique requires a comprehensive evaluation that considers various well and reservoir characteristics. Here’s a deeper dive into the factors influencing this crucial decision:

1. Reservoir Geology:

Rock Type: Sandstone formations often benefit from acidizing to dissolve mineral deposits like calcium carbonate. Shale formations, on the other hand, might require hydraulic fracturing to create and maintain flow channels due to their naturally low permeability.

Permeability: Formations with extremely low permeability, like tight sandstones or shales, might necessitate a combination of techniques. For instance, matrix acidizing could be used alongside hydraulic fracturing to create a network of conductive pathways within the rock matrix.

Formation Damage: Identifying the type and location of formation damage is essential. Acidizing is well-suited for removing carbonate deposits, while mechanical techniques like jetting might be better suited for clearing debris near the wellbore.

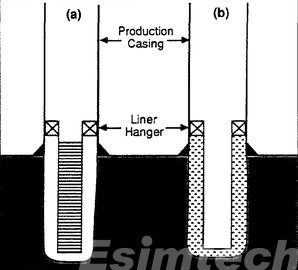

Casing and Cement Integrity: The strength and integrity of the wellbore casing are crucial for withstanding the high pressures associated with hydraulic fracturing. If casing integrity is compromised, acidizing or other less-intensive methods might be preferred.

Perforation Design: The size, density, and distribution of perforations in the wellbore casing determine the area of communication between the wellbore and the reservoir. Understanding the perforation design helps tailor the stimulation technique to effectively reach the target formation zone.

3. Production History:

Production Decline Curve: Analyzing the well’s historical production data can reveal the nature of the decline. A sudden drop might indicate formation damage near the wellbore, while a gradual decline could suggest deeper issues requiring a more intensive stimulation approach.

Fluid Analysis: Studying the composition of produced fluids can provide clues about the type of formation damage. The presence of sand or scale can indicate the need for mechanical cleaning or acidizing, respectively.

4. Economic Considerations:

Cost-Effectiveness: Each stimulation method has associated costs, including mobilization, equipment, chemicals, and operational expenses. Evaluating the expected production gains needs to be balanced against the investment required for each technique.

Return on Investment (ROI): The chosen method should offer a positive ROI by significantly improving production rates at a cost that is outweighed by the additional revenue generated.

5. Additional Factors:

Environmental Regulations: Compliance with environmental regulations plays a role. Techniques with lower water usage or reduced surface footprint might be preferred in environmentally sensitive areas.

HSE Considerations: Health, Safety, and Environment (HSE) considerations are paramount. Techniques with lower risks of wellbore integrity issues or fluid leaks are often preferred.

Conclusion

Effective utilization of well stimulation technologies is crucial for sustaining and improving oil and gas extraction. With a grasp of various stimulation techniques and their appropriate uses, operators can strategically optimize well performance, maximizing output over the entirety of their operational lifespan.