What Do You Know About Drilling Engineering

Drilling engineering is a specialized field in petroleum and mining engineering that focuses on the design, planning, and execution of drilling operations. It plays a pivotal role in extracting valuable resources from beneath the Earth’s surface, such as oil, natural gas, and minerals. This article delves into the fundamental aspects of drilling engineering, including its definition, the intricate process it entails, the key technologies and tools employed, and the indispensable role of simulation technology.

What is Drilling Engineering?

Drilling engineering is a specialized branch of petroleum engineering that focuses on the design, planning, and execution of drilling operations for extracting subsurface resources such as oil and natural gas. It encompasses a wide range of activities related to the drilling process, aiming to optimize the efficiency, safety, and cost-effectiveness of drilling operations.

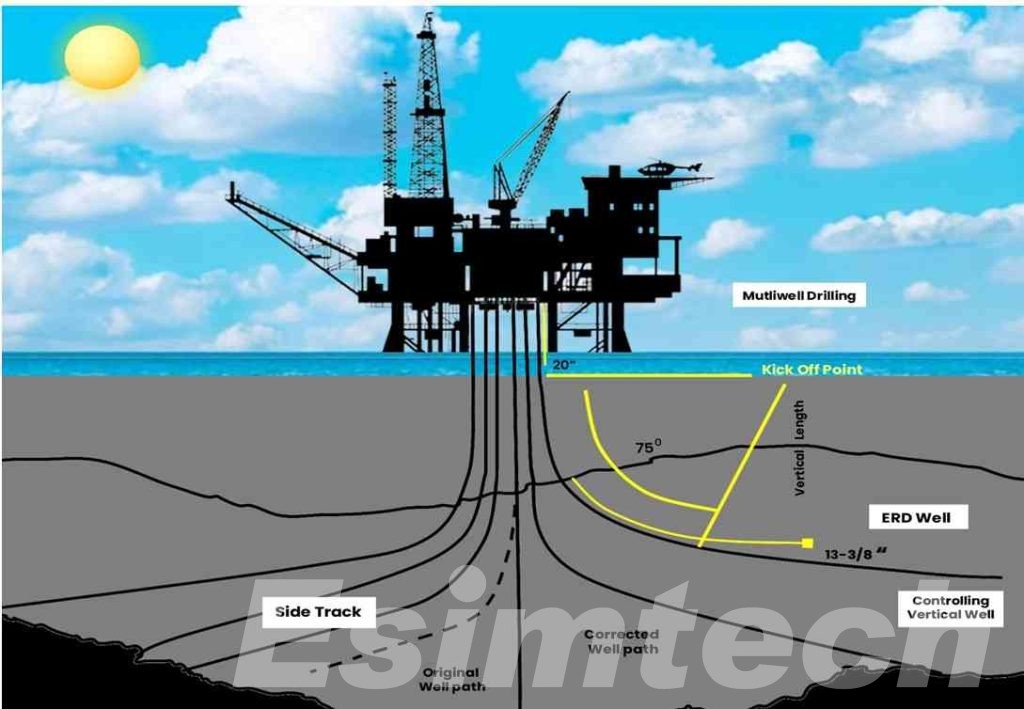

Key aspects of drilling engineering include well design, selection of drilling equipment, drilling fluid management, and drilling optimization. Engineers in this field work to develop strategies for penetrating the Earth’s crust, and encountering and extracting hydrocarbons from reservoirs beneath the surface. They evaluate geological formations, design well trajectories, and implement drilling techniques that balance technical feasibility with economic viability.

Drilling engineers must also address challenges such as wellbore stability, pressure control, and environmental considerations. With advancements in technology, drilling engineering has evolved to incorporate innovations like directional drilling, automated drilling systems, and real-time data monitoring. Successful drilling engineering plays a crucial role in the overall success of oil and gas exploration and production projects.

The Process of Drilling Engineering

The process of drilling engineering is a complex and multifaceted endeavor that involves several key stages, from initial planning to the execution of drilling operations. This specialized branch of petroleum engineering is essential for the extraction of subsurface resources, predominantly oil and natural gas. The following outlines the sequential steps and considerations involved in the process of drilling engineering.

1. Planning and Design

- Geological Analysis: Understanding the target formation, its depth, rock properties, and potential hazards is essential. This involves interpreting seismic data, well logs, and other geological information.

- Wellbore Design: Drilling engineers determine the optimal wellbore trajectory, considering factors like formation geometry, reservoir pressure, and completion equipment requirements. They design the casing and tubing program, ensuring the well’s stability and integrity throughout its lifespan.

- Drilling Fluids: Selecting the appropriate drilling fluid is crucial for maintaining wellbore pressure, removing cuttings, and preventing formation damage. Engineers consider factors like viscosity, lubricity, and environmental impact when choosing the fluid system.

- Cost Estimation and Budgeting: Drilling projects can be expensive, so engineers meticulously plan and budget for equipment, materials, personnel, and potential contingencies.

2. Rig Selection and Preparation

- Choosing the Right Rig: The type of drilling rig depends on the well depth, formation characteristics, and desired drilling speed. Engineers select rigs based on their capabilities and cost-effectiveness.

- Rig Inspection and Maintenance: Ensuring the rig’s equipment is in top working order is critical for safety and efficiency. Engineers perform thorough inspections and preventive maintenance before commencing operations.

- Personnel Training and Safety: Drilling involves inherent risks, so thorough training and safety protocols are paramount. Engineers ensure all personnel understand their roles and responsibilities, and proper safety equipment is readily available.

3. Drilling Operations

- Wellbore Initiation and Drilling: The drilling process begins with breaking ground and constructing a wellbore using specialized bits rotating on a drill string. Engineers monitor drilling parameters like weight on bit, rate of penetration, and fluid circulation to optimize performance and prevent problems.

- Logging and Formation Evaluation: Logging tools are lowered down the wellbore to gather data about the formation, including rock properties, fluid content, and potential hydrocarbons. This information helps engineers make informed decisions about well completion and production.

- Casing and Cementing: Casing sections are installed and cemented in place to stabilize the wellbore, prevent formation fluids from entering, and protect the environment.

4. Well Completion and Production

- Stimulation and Completion Techniques: Depending on the formation and reservoir characteristics, engineers might employ various techniques like perforations, fracturing, or acidization to enhance production. Completion equipment like pumps and downhole valves are installed to control production and ensure well integrity.

- Testing and Production: The well is tested to determine its production potential and ensure it meets regulatory requirements. Once deemed successful, the well is connected to production facilities and begins delivering the targeted resource.

5. Monitoring and Maintenance

- Data Acquisition and Analysis: Drilling and production data are continuously monitored to identify potential problems, optimize performance, and ensure reservoir health. Engineers analyze this data to adjust operations and prevent equipment failures.

- Well Maintenance and Workovers: Over time, wells may require interventions like cleaning, repairs, or stimulation treatments to maintain optimal production. Engineers plan and execute these workover operations to extend the well’s life and maximize resource recovery.

6. Decommissioning and Environmental Considerations

- Completion of Well Abandonment: As a well approaches the conclusion of its productive lifespan, it necessitates meticulous abandonment procedures to avert environmental contamination and guarantee safety. This entails the thorough sealing of the wellbore and the adherence to regulatory guidelines for the removal of surface equipment.

- Mitigation of Environmental Impact: The drilling process may entail adverse environmental effects, prompting engineers to employ strategies aimed at mitigating these impacts. These measures encompass effective waste management, preventative measures against spills, and the adoption of responsible land use practices to curtail the ecological footprint associated with drilling activities.

Key Technologies and Tools of Drilling Engineering

Drilling engineering relies on a diverse set of technologies and tools to effectively explore and extract hydrocarbons from the Earth’s subsurface. These key tools and technologies include:

1. Drilling Rigs:

Modern drilling rigs are equipped with advanced technology for drilling wells. They come in various types, including conventional rotary rigs, top drive systems, and automated rigs. These rigs provide the necessary mechanical power to turn the drill bit and penetrate the Earth’s crust.

2. Drill Bits:

Drill bits are crucial components that cut through rock formations during drilling. There are different types of drill bits, such as roller cone bits and fixed-cutter bits, each designed for specific geological conditions. Diamond and tungsten carbide materials are commonly used to enhance durability.

3. Directional Drilling Technology:

Directional drilling allows engineers to control the trajectory of the wellbore, enabling access to reservoirs that are not directly beneath the drilling rig. This technology is vital for reaching specific targets and optimizing resource recovery.

4. Mud Pumps and Drilling Fluids:

Mud pumps circulate drilling fluids, commonly known as mud, to cool and lubricate the drill bit, control downhole pressure, and carry cuttings to the surface. The composition and properties of drilling fluids are carefully managed to suit different geological conditions.

5. Measurement While Drilling (MWD) and Logging While Drilling (LWD) Tools:

MWD tools provide real-time data on drilling parameters such as wellbore direction and inclination. LWD tools capture geological and petrophysical data during the drilling process, offering valuable insights into the subsurface formations.

6. Casing and Cementing Equipment:

Casing is used to line the wellbore and prevent it from collapsing. Cementing equipment ensures the proper sealing of the annulus between the casing and the rock formation, enhancing well integrity and preventing fluid migration.

7. Well Control Systems:

Well control systems are critical for maintaining pressure in the wellbore to prevent blowouts and other hazardous incidents. Blowout preventers (BOPs) and other safety mechanisms are essential components of well control.

8. Automated Drilling Systems:

Automation technologies, including robotics and artificial intelligence, are increasingly being integrated into drilling operations. These systems enhance drilling efficiency, reduce human intervention, and improve safety.

9. Real-time Monitoring and Data Analytics:

Advanced sensors and real-time monitoring systems provide continuous feedback on drilling conditions. Data analytics tools help in processing and interpreting this information, enabling prompt decision-making and optimization of drilling parameters.

10. Managed Pressure Drilling (MPD) Systems:

MPD systems control wellbore pressure dynamically, allowing for the drilling of challenging formations. This technology enhances safety and efficiency by preventing kicks and wellbore instability.

11. Drilling Software:

Specialized drilling software assists in the planning, simulation, and real-time monitoring of drilling operations. It helps engineers make informed decisions and optimize drilling parameters.

The integration of these technologies and tools in drilling engineering plays a pivotal role in enhancing efficiency, safety, and the overall success of oil and gas exploration and production projects.

Conclusion

In conclusion, drilling engineering is a multidisciplinary field essential for the extraction of Earth’s valuable resources. The meticulous planning, advanced technologies, and simulation tools employed in drilling engineering underscore its significance in the exploration and extraction of oil, gas, and minerals. As technology continues to evolve, drilling engineering will undoubtedly play a pivotal role in unlocking new frontiers and ensuring sustainable resource development.