What’s the Role of Directional Drilling in Offshore Oil and Gas Exploration

Offshore oil and gas exploration keeps getting tougher as people dig deeper and face tougher ocean environments. Standard vertical drilling can’t always reach oil or gas layers that lie far below and come up at sharp angles. That’s when directional drilling steps in and changes the game.

Directional drilling in oil and gas gives the crew on the rig the power to bend and steer the hole while the drill bit is still spinning. Because the wellbore can be adjusted at any point, operators drill just far enough to hit the target reservoir, and they skip drilling through layers that may be of little or no use. The result? Drilling is faster, reflections of rock stress reduce the chance of drill breakage or stuck pipelines, emissions and waste are lower, and the number of separate platform footprints can be cut in half, safeguarding the delicate ocean ecosystem. Let’s break down the steps and see why directional drilling is now a must-have for any offshore drilling program.

What is Directional Drilling?

Directional drilling lets oil and gas companies drill wells at angles other than straight down, so they can reach fuel locked in tough spots. While standard vertical drilling just goes straight down, this method curves, bends, and straightens to keep the drill on the smart path through underground shapes, even when they slope.

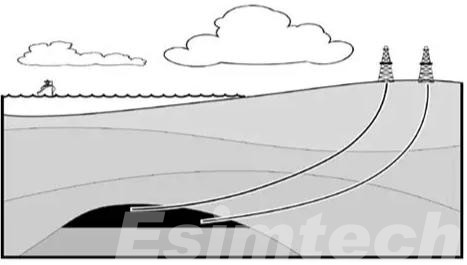

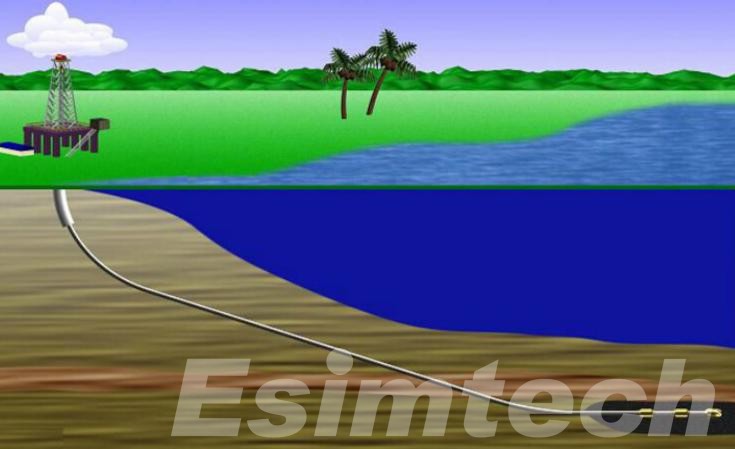

Now engineers use this method a lot, especially at sea. Deepwater rigs have to share tight pads on floating platforms, and the oil often hides behind tough rock layers. By using GPS-type tools and screens that show data in real time, drillers can push pipes sideways fifteen miles or more, tapping wells under sea or tricky underwater reefs without drilling through the seabed in the first place.

Steering drills this way brings other big wins. One angled hole can reach more fuel, so drillers need fewer rigs. That saves money, lowers the total days spent on expensively rented rigs, and cuts the truck and pipe traffic at the port. By landing a hole in the right place they also avoid all the effort and fuel of extra wells, so the result leaves a leaner, cleaner operation with fewer miles of extra road and fewer stacks of metal on the beach later.

Key Technologies and Techniques in Directional Drilling

Directional drilling has become the backbone of successful offshore oil and gas exploration because of cutting-edge tech that keeps the well path on target. Today’s offshore drill crews mix mechanical upgrades, live monitoring, and digital modeling to cut through tricky rock layers both quickly and securely.

- At the heart of the operation sits the rotary steerable system, or RSS. This system keeps the drill string spinning as it gently pivots the well on its designed path. The result? Smoother bends that avoid clogging and speed the whole job up. Complementing the RSS, downhole motors make a gentle turn at the bit, allowing drillers to nudge the hole a few degrees whenever necessary.

- The second layer of wizardry comes from Measurement-While-Drilling and Logging-While-Drilling tools. MWD measures the well’s angle and compass heading 24/7. LWD, meanwhile, records rock type, pressure, and the kind of fluid a layer holds. The combo delivers a constant data stream that lets crews re-plan the path on the fly, cutting surprise costs.

- Before any bit touches rock, engineers lean on powerful modeling software to virtual-drill the best path. They try every alternative on a laptop, mapping squiggles on a 3D world, to avoid mishaps in the real deal. These layered tech breakthroughs fuse together to turn offshore directional drilling into a rock-solid and extremely quick way to tap deep-water fields.

How Directional Drilling Works in Oil and Gas Exploration

- Planning the Well Trajectory

Before putting any equipment in the water, oil and gas companies start by designing the well. Engineers look at geological surveys, seismic readings, and the properties of the oil or gas reservoir to draw a path that gets the most fuel while keeping danger to a minimum. Powerful computer programs model different drilling routes, letting the team pick the fastest and safest one long before the bit turns. All this prep work locks in an accurate path so the well can hit the jackpot, even under the tricky conditions of an offshore field.

- Drilling the Vertical Section

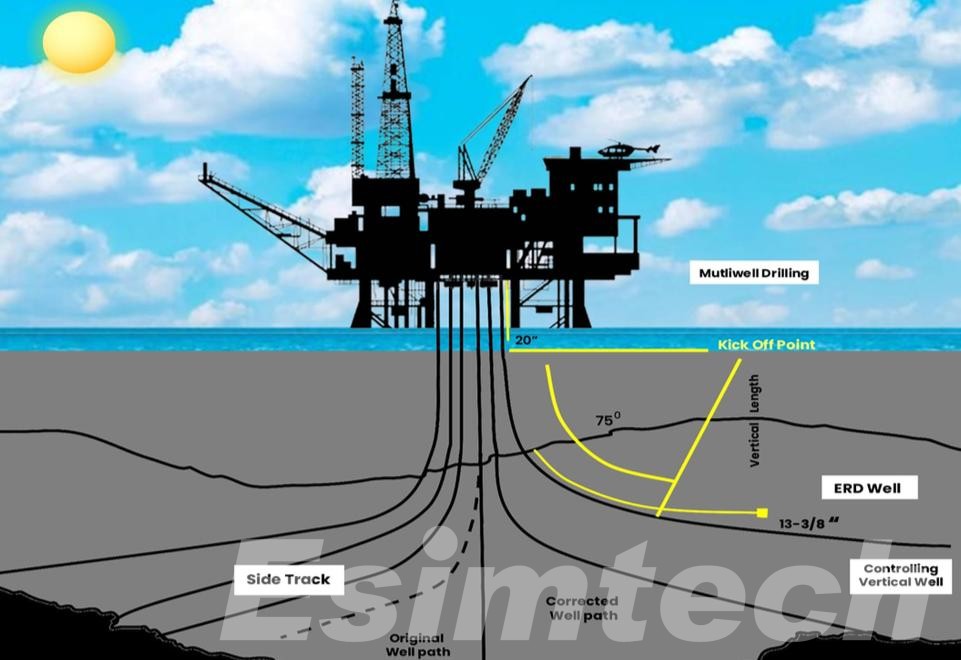

With the plan locked in, the crew drills straight down from the platform to a set depth. This vertical hole locks in the path, making sure the well is set up right before any turning happens. Engineers mix standard drilling tools with live data tracking to keep the hole safe and on course.

- Steering the Wellbore

When the vertical section is finished, the bit starts to shift from vertical. Electrical motors called rotary steerable systems (RSS) or downhole mud-powered motors change the well’s angle without stopping. These tools guide the bit precisely. Meanwhile, Measurement-While-Drilling (MWD) sensors stream live data on tilt (inclination) and compass heading (azimuth). Logging-While-Drilling (LWD) tools gather information on rock type, pore pressure, and fluids. Engineers analyze the data on the surface and instantly adjust the bit’s angle to stay on the planned path.

- Horizontal and Extended-Reach Drilling

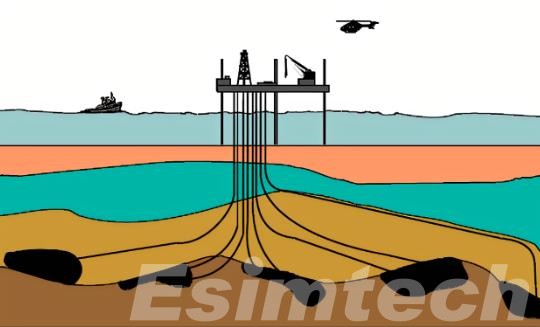

Rigs need to drive long horizontal holes to reach the oil and gas lock down in offshore reservoirs. Directional drilling makes it possible to run miles of horizontal hole, connecting several reservoir sections from a single well pad. Extended-reach holes can run kilometers horizontally beneath the seabed. Steering long sections from one rig cuts costs and fewer platforms means less impact on coastal and marine ecosystems.

- Continuous Monitoring and Optimization

MWD and LWD systems never stop reporting data. Engineers watch the trends on screens, making fine adjustments to drilling settings: how hard the bit pushes (weight on bit), how fast it spins (rotational speed), and how fast the mud circulates (mud flow). Balancing these variables keeps operations fast, safe, and gentle on the rock reservoir.

Combining cutting-edge technology, detailed planning, and constant data reviews, offshore directional drilling delivers oil and gas with precision and minimal risk.

The Role of Directional Drilling in Offshore Exploration

Directional drilling has established itself as an indispensable capability in offshore oil and gas exploration by permitting the exploitation of reservoirs that traditional vertical drilling would render impractical or uneconomic. In the offshore context, where drilling installations entail significant capital expenditure and where real estate on the seafloor is inherently constrained, the technique facilitates optimal hydrocarbon extraction from a single wellsite.

- A primary commercial incentive undergirding the application of directional drilling is its capacity to interrogate multiple reservoir intervals from a single drilling template. By directing wells along preplanned azimuth and inclination profiles—often incorporating sophisticated 3D modelling—engineers can intercept fault-blocks, sweep oil columns, or sidestep occupied lease boundaries while maintaining a compact drilling footprint. Such geometric versatility suppresses the mobilization of redundant semi-submersibles or jack-ups, yielding pronounced cost savings and a concomitant decrease in physical and visual rig and subsea footprint.

- Operationally, the method delivers pronounced safety and efficiency dividends. Precise directional steering enables the well to bypass competent rock masses, unstable zones, or subsurface high-pressure anomalies, thereby mitigating geohazards that could jeopardize personnel integrity and equipment longevity. The combination of real-time downhole monitoring and advanced geosteering ensures optimal trajectory conformance, translating into higher deliverability coefficients and improved recovery factors.

- Finally, directional drilling substantially advances the social license for offshore exploration by curtailing the total platform count and scope of seafloor disturbance, thus mitigating the potential for interference with sensitive benthic and pelagic habitats. This capacity to intertwine economic appeal with heightened operational efficiency and a rigorous commitment to sustainability has rendered the technique not merely a functional option, but a strategic imperative within the contemporary drilling playbook.

Final

Directional drilling is changing the game for exploring oil and gas beneath the ocean floor. By fusing precise engineering with cutting-edge tech, the method opens up hard-to-reach oil and gas deposits, drives down costs, and protects the marine environment.

With the world’s energy needs shifting, the offshore sector will lean even more on directional solutions. These methods let operators balance efficiency, safety, and sustainability—key goals everyone is focused on meeting today.