What is Slimhole Drilling

Although conventional oil and gas drilling methods remain prevalent, slimhole drilling is gaining traction due to its cost-reduction benefits. As new unconventional reservoirs are being explored these days, as well as with the global demand for a reduced ecological footprint clamouring, this technology is swiftly becoming a remarkable answer. This guide will cover the basics of slimhole drilling, including its operational workflow, advantages compared to other wireless techniques, and traditional drilling methods.

Introduction to Slimhole Drilling Basics

Slimhole drilling is a targeted drilling method designed to create wells with smaller diameters compared to traditional drilling. Instead of wide boreholes that require significant material and infrastructure, slimhole operations focus on precision and efficiency. This approach aligns with the evolving priorities of the energy industry, including cost reduction, environmental stewardship, and improved access to complex or remote formations.

What sets slimhole drilling apart is not just the smaller hole size, but the entire system tailored around it. From compact slim-hole drilling rigs to specially engineered downhole tools, every component is optimized for narrow wellbores. This results in lighter equipment loads, quicker mobilization, and streamlined well design.

The technique is especially advantageous in early-stage exploration, where minimizing investment and surface impact are critical. Additionally, with advancements in slim hole drilling technology, such as high-resolution formation logging tools and steerable drilling systems, operators can still gather detailed subsurface data despite the reduced hole size.

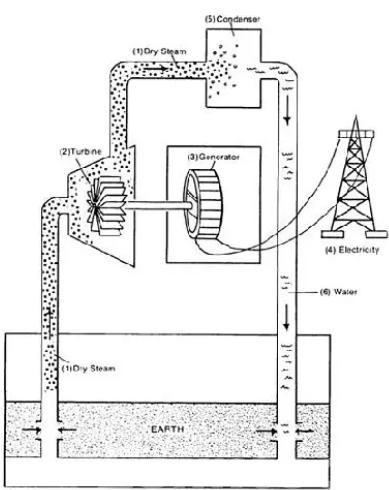

Slimhole drilling is no longer just a niche technique—it has matured into a reliable, field-proven method used worldwide in oil, gas, geothermal, and even environmental projects.

How Does Slimhole Drilling Work?

As with traditional drilling, slimhole drilling operates with an emphasis on precision. Unlike older techniques, new methods employ sophisticated instruments to achieve narrower boreholes and are tailored towards efficiency or minimal ecological disruption. Below is a summary of the main processes involved:

1. Rig Setup & Mobilisation

Quick setup and transportation characterise everything about slimhole rigs - they are both light and compact. Limited infrastructure or space requirements mean these mobile rigs can even navigate rougher terrains and remote locations.

2. Drill Bit & Tool Selection

Slim hole drillings do not require heavy machinery because they operate with smaller drill bits (3-6 inches). These are advanced PDC (Polycrystalline Diamond Compact) or diamond impregnated bits which ensure toughness at reduced weight dimensions.

Real-time data collection related to the formation characteristics, well angle, and other drilling parameters uses downhole tools such as MWD (Measurement While Drilling) and LWD (Logging While Drilling), further streamlining the process.

3. Drilling Process

Oil rigs employ electrical patterns like other parts of industry, while pumping controlled hydraulic pressures in a uniform manner during the bit operation increases productivity throughout these cycles.

Wellbore stabilization, cooling/minimising pumping issues/zeroing incapacitance mud systems leverage high-pressure liquids/fluids to discharge from offshore stations for efficient sediment removal along boring sections.

In comparison to wider holes, small diameter cuts significantly reduce effluents released as harmful waste, offering greater eco-friendly benefits over and above the added value that traditional explorers termed these drills as just another expense layer instead of appreciating their importance and added brilliance all round.

4. Casing & Completion

Materials expenses are reduced for slimhole wells because they often employ slimmer, lightweight casing strings.

Some operations use expandable casing technology to reinforce the wellbore while still keeping the diameter intact.

Completion procedures uniquely allow slimhole-compatible perforation tools that ensure efficient production or testing.

5. Logging & Evaluation

Reservoir characteristics can be assessed using advanced sensors and logging tools through the narrow borehole. Receiving data in real-time enables prompt decisions by operators, achieving optimal drilling efficiency.

6. Reduced Footprint & Waste Management

Smaller volumes of cuttings not only reduce environmental impact but also simplify disposal efforts.

Compact rig setups substantially reduce surface disturbance, which is desirable when drilling in sensitive ecosystems or urban settings.

Operators achieve deeper and more precise wells with fewer resources when utilising slimhole drilling technology, making this approach advantageous for contemporary exploration and production demands.

Why Use Slimhole Drilling

The adoption of Slimhole drilling has risen across different sectors because it is more efficient, less costly, and reduces the environmental impact. Here’s further reasoning on why companies prefer this modern method of drilling:

1. Reduced Cost per Operation: Compared to conventional drilling, slimhole drilling uses smaller rigs which means less fuel as well as reduced expenditure of materials. The reduced hole diameter also means that less drilling fluid will be used alongside waste disposal which cuts expenses significantly. Additionally, the compact, slim hole drilling rig needs a smaller crew which improves labour cost efficiency.

2. Minimal Environmental Footprint: Due to stricter regulations set by environmental groups, slimhole offers a sustainable solution for minimal ecological footprint. The small borehole size creates lesser wastes which leads to reduced soil disturbance and lowered contamination risks – making it useful for ecologically sensitive regions where traditional drilling wouldn't work.

3. Faster Deployment & Mobility: Increased portability of the slim hole makes its drilling rigs lightweight and more compact which allows for easier transportation and setup in remote areas or hard-to-reach places. Such agility accelerates exploration while reducing downtime which is ideal for projects bound by time constraints.

4. High Precision & Advanced Technology: With respect to recovery precision in resources like oil and gas alongside geothermal drilling, modern slim hole drills include advanced sensors and real-time data monitoring systems improving accuracy in well placement during extraction operations.

5. Optimal for Exploration and Deep Wells: Slimhole drilling is especially useful for exploratory wells, allowing companies to evaluate reservoirs at a lower cost. It is also beneficial in scenarios concerning deep drilling, where traditional rigs face difficulties.

Slimhole drilling is revolutionising the future of resource extraction because of the considerable savings, environmental advantages, and operational flexibility it offers.

Applications of Slimhole Drilling in Oil and Gas

In the oil and gas industry, slimhole drilling techniques have revolutionised exploration and field development. The technique's smaller wellbore diameter of 3 to 6 inches makes its application versatile. For instance:

- Exploratory Drilling: Operators can utilise this technology for test well construction due to the low costs associated with slimhole drilling compared to traditional methods. This poses great value for frontier areas where potential reservoir yields are unknown.

- Marginal Field Development: A large number of small reservoirs or depleted fields remain unexploited due to the economically unviable nature of conventional drilling practices on them. Slimhole drilling enhances economic efficiency as it cuts down operational costs, enabling profitable extraction of remaining reserves post-drilled abandonment. Moreover, reduced footprint rigs make these sensitive ecological zones more accessible, conserving untouched nature.

- Side Tracking & Re-Entry Wells: Closely related to the previously mentioned techniques, short horizontal boreholes significantly improve re-entry efficiency into existing wells, thus circumventing blockages and reaching untouched zones, thereby elongating aging fields' productive lifecycle without incurring expensive new wellbore costs.

- Data Acquisition & Coring: Optimising production strategies requires precise reservoir information that advanced slim hole drill technologies increase accurate core sampling and real-time data collection, streamlining slim bore technology targets and boosting productivity.

The ongoing innovation in oil and gas operations, especially in difficult or expensive regions, is attributed to slimhole drilling due to its convenience and effectiveness. It is an essential technique for modern energy exploration substitutes because it combines cost-effectiveness with performance.

Slimhole Drilling vs. Conventional Drilling

Although both styles of drilling seek to obtain subsurface resources, they differ considerably in scale, efficiency, and environmental impact. Slimhole drilling attempts to create narrower boreholes using miniature rigs and specialised tools which is ideal for remote locations or projects with strict environmental limits and is cost-effective. The direct opposite is conventional drilling which has less operational flexibility due to complex production wells or higher costs of operation and larger footprint.

| Aspect | Slimhole Drilling | Conventional Drilling |

| Borehole Diameter | Less than 6 inches | 8 to 12+ inches |

| Rig Size | Compact, portable slim hole drilling rig | Larger, more robust rig systems |

| Cost | Lower (less steel, mud, fuel) | Higher (more materials and time required) |

| Drilling Speed | Faster in suitable formations | Slower due to larger volume and complexity |

| Environmental Impact | Reduced surface footprint and waste | Greater environmental disturbance |

| Data Acquisition | More limited, but improving with modern tools | Easier with larger logging and testing tools |

| Best Use Cases | Exploration, remote areas, geothermal, science | High-volume production wells, complex geology |

This side-by-side comparison highlights the strategic use of slimhole drilling where speed, efficiency, and lower impact are prioritized over maximum output.

Summary

The method of well construction known as slimhole drilling is contemporary in nature and more efficient from both an economic and ecological perspective. The usage of a slim hole drilling rig alongside a modern piece of equipment termed a “slim hole drill” enables faster and more economical narrower well completion while retaining the capability for necessary data gathering and production extraction. Slimhole drilling serves as a prudent solution today in the energy extraction landscape, whether in oil or gas exploration, geothermal undertakings, or even scientific endeavours.