What Types of Drilling Rigs Are There?

Drilling rigs are essential tools used in the exploration, extraction, and construction industries. They are used to bore deep holes into the earth’s surface, allowing for the extraction of valuable resources such as oil and gas, minerals, and water. Drill rigs come in various shapes and sizes, each designed to meet specific drilling requirements. Understanding the different types of drill rigs and their capabilities is critical in selecting the appropriate equipment for a particular drilling project. In this article, we will explore the main types of drill rigs and their functions, providing a comprehensive guide to the world of drilling technology.

What is a Drilling Rig?

A drilling rig is a machine used to create holes or wells in the ground for various purposes, including exploration and extraction of natural resources such as oil, gas, and minerals, as well as for construction and geotechnical investigations. Drilling rigs are typically mounted on trucks, trailers, or skids and are equipped with various drilling tools such as drill bits, drill pipes, and drilling mud systems. The rigs can be powered by electricity, diesel engines, or hydraulic systems, and they come in various sizes and configurations to suit different drilling requirements. The drilling process involves rotating the drill bit to create a borehole, which is then cased and cemented to prevent collapse and contamination of the surrounding formation. Drilling rigs are critical tools in a wide range of industries and play a significant role in the global economy.

What is the Function of the Drilling Rig?

A drilling rig is a mechanical device that drives a drilling tool to drill underground to obtain physical geological data during the process of exploring or developing mineral resources.

The primary function of a drilling rig is to create holes or wells in the ground for various purposes. The main function of the drilling rig is to drive the drilling tool to break the rock at the bottom of the hole, and to lower or raise the drilling tool in the hole. It can be used to drill cores, ore cores, cuttings, gaseous samples, liquid samples, etc., to ascertain the conditions of underground geology and mineral resources. The specific function of a drilling rig depends on the type of drilling being performed, which can include:

- Exploration drilling: Used to locate and evaluate subsurface resources such as oil, gas, and minerals.

- Production drilling: Used to extract oil, gas, and minerals from the subsurface.

- Geotechnical drilling: Used to obtain soil and rock samples for engineering and construction purposes.

- Environmental drilling: Used to sample soil and groundwater for contamination and monitor groundwater levels.

- Water well drilling: Used to create wells that provide a source of drinking water for households and businesses.

- Construction drilling: Used to create holes for building foundations, bridges, and other structures.

In addition to creating holes, drilling rigs also play a crucial role in well completion and maintenance. They are used to install casing and tubing to prevent collapse and contamination of the wellbore, as well as to perform well intervention activities such as well stimulation and remediation. Overall, drilling rigs are essential tools that enable us to access and utilize the Earth’s subsurface resources.

What Are the Main Types of Drilling Rigs According To Classification Methods?

Drilling rigs come in various shapes, sizes, and configurations, and each is designed to perform a specific drilling task. In the world of drilling technology, understanding the different types of drilling rigs is crucial in selecting the appropriate equipment for a particular drilling project. Here we list the mains types of drilling rigs according to different classification methods:

Drilling equipment usually has the following types:

- 1. Conventional land drilling rigs

- 2. Desert Rig

- 3. Vehicle-mounted drilling rig

- 4. Coiled tubing machine

- 5. Deviated Well Drilling Rig

- 6. Offshore drilling platform

- 7. Drillship

1. According to the drilling method

- (1) Impact drilling rigs, such as wire rope impact drilling rigs, vibration drilling rigs, etc.

- (2) Rotary drilling rigs, such as drilling rigs used in rotary table drilling.

- (3) Downhole power drilling tools, such as turbo drilling tools, screw drilling tools, electric drilling tools, etc.

2. According to drilling and depth classification

- (1) Ultra-deep well drilling rig. A drilling rig with a diameter of 114mm drill pipe, a nominal drilling depth of more than 7,000 meters and a maximum hook load of more than 4,500 kN is used.

- (2) Deep well drilling rig. A drilling rig with a diameter of 114 mm drill pipe, a nominal drilling depth of 4000-7000 meters and a maximum hook load of 2250-4500 kN

- (3) Medium and deep well drilling rigs. A drilling rig with a diameter of 114 mm drill pipe, a nominal drilling depth of 1500-4000 meters and a maximum hook load of 900-2250 kN is used.

3. According to power equipment

- (1) Diesel engine drives the drilling rig. A drilling rig powered by a diesel engine through mechanical transmission or hydraulic transmission.

- (2) AC drive drilling rig. It is suitable for use in oil fields with industrial power grids.

- (3) DC drive drilling rig. The working unit is driven by a DC motor.

4. According to the driving mode

- (1) Drive alone. Each working machine is individually driven by generators of different sizes, which are mostly used for electric drive. The transmission is simple and the installation is easy, but the power utilization rate is low and the total mass of the equipment is large.

- (2) Unified drive. The same power unit drives the three working groups of the drawworks, drilling pump, and turntable. This method is used by most rigs. Only one drilling pump can be included in the unified drive; the other drilling pump is operated separately. Although the unified drive drilling rig can be adjusted mutually when the engine fails and has a high power utilization rate, the transmission is difficult to install and modify, and its efficiency is low.

- (3) Group drive. The combination of power is between independent drive and unified drive. The power utilization rate of this kind of drilling rig is higher than that of a single drive. It is also possible to install two groups of working machines on different heights and scattered sites.

What Drill Rig is Most Commonly Used?

The type of drilling rig that is most commonly used depends on the specific application and geological conditions of the drilling project. However, one of the most commonly used types of drilling rigs is the rotary drilling rig, also known as a conventional drilling rig.

Rotary drilling rigs are versatile machines that can be used for a variety of drilling applications, including oil and gas exploration and production, geothermal drilling, and water well drilling. They are typically mounted on trucks or trailers and are powered by diesel engines. Rotary drilling rigs use a rotary bit to drill into the earth’s surface, and drilling mud is circulated through the drill string to cool and lubricate the bit, as well as to carry the cuttings to the surface.

While rotary drilling rigs are commonly used, other types of drilling rigs are also used depending on the specific drilling project’s requirements, such as cable tool drilling rigs, top drive drilling rigs, and directional drilling rigs. Each type of drilling rig has its own advantages and limitations, and the choice of rig will depend on the geological conditions, drilling objectives, and budget constraints of the project.

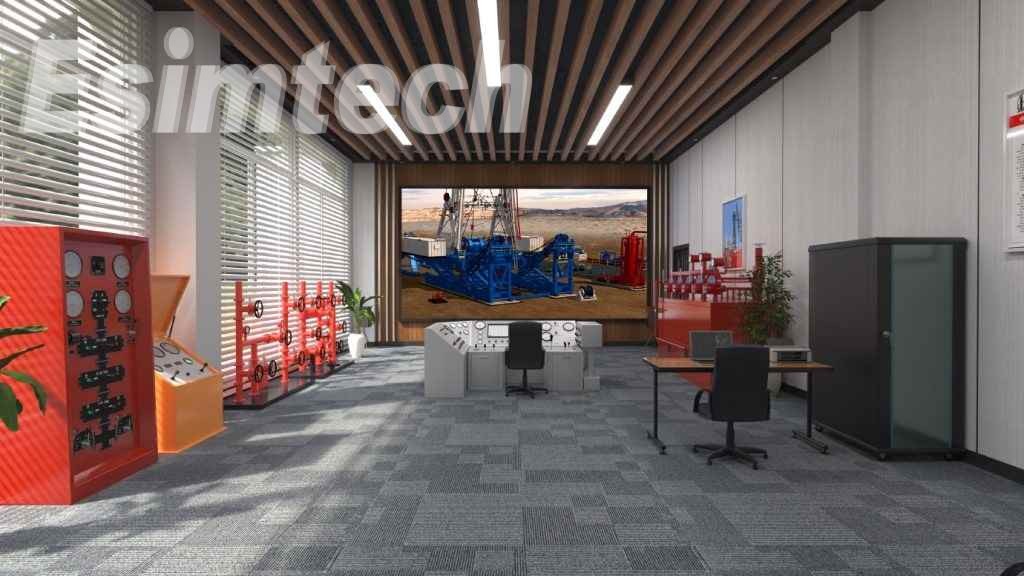

Esimtech is a high-tech enterprise integrating scientific research, design, production, maintenance, sales and computer application technology in the oil and gas industry. Committed to the simulation system development of petroleum engineering and petroleum equipment, a series of application results with completely independent intellectual property rights have been achieved, and a number of domestic and international patents have been obtained, and it has become a member of IADC and IWCF.

It has developed petroleum engineering over the course of more than 20 years through perseverance and unceasing efforts, including drilling, well control, logging, oil and gas production, downhole operations, oil and gas gathering and transportation, fracturing and acidizing, drilling rig installation, coiled tubing, and snubbing operations. The full range of application sites for the oil and gas sector is covered by our product line.