Why Floating Production Storage and Offloading Units are Important in Offshore Energy Extraction

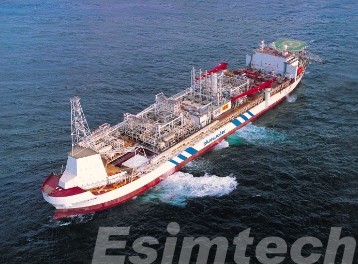

Floating Production Storage and unloading (FPSO) units have emerged as game changers in the ever-changing environment of offshore energy extraction, providing a versatile and efficient solution for the production, storage, and unloading of hydrocarbons at sea. This article explores the multifaceted world of floating production storage and offloading units, shedding light on their design, functions, applications, the pivotal role they play in the offshore energy industry and the advancements for them

Understanding Floating Production Storage and Offloading Units

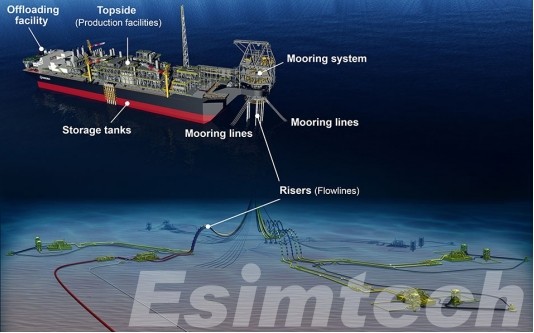

FPSO units, which are at the center of offshore oil and gas operations, are a hybrid platform that combines production, storage, and offloading capabilities into a single, floating structure. This novel technology enables energy corporations to access remote and deepwater reserves where standard permanent platforms would be unfeasible or prohibitively expensive.

Design and Key Components of Floating Production Storage and Offloading Units

1. Hull Design

FPSOs typically feature a ship-shaped hull designed for stability and mobility in offshore environments. Equipped with dynamic positioning systems and thrusters, these vessels can maintain their position and orientation even in challenging sea conditions.

2. Topside Facilities

The topside facilities of an FPSO house essential components such as oil and gas processing modules, water separation units, and gas compression facilities. These sophisticated facilities enable the extraction and processing of hydrocarbons directly at the production site.

3. Storage Tanks

Large storage tanks within the FPSO serve as repositories for processed oil and gas, providing a temporary storage solution until the hydrocarbons are ready for offloading.

4. Offloading Systems

Offloading systems on FPSOs efficiently transfer stored hydrocarbons onto shuttle tankers or pipelines, assuring continuous transportation to refineries.

Applications and Operational Flexibility of Floating Production Storage and Offloading Unit

1. Deepwater Exploration

Deepwater exploration is especially well-suited to FPSO units, which allow energy corporations to reach previously undiscovered resources in deep offshore regions.

2. Marginal Field Development

When fixed platforms are not economically viable, FPSOs provide a cost-effective alternative for developing marginal oil and gas fields.

3. Temporary Production Needs

FPSOs are frequently used for short-term production demands, providing a flexible alternative for projects with shorter life cycles.

Advantages of Floating Production Storage and Offloading Units

1. Mobility and Versatility

FPSOs can be strategically placed in a variety of offshore locations to accommodate varying sea depths and geological conditions.

2. Cost-Efficiency

FPSOs can be more cost-effective than typical fixed offshore platforms, especially for short-term or smaller-scale projects.

3. Rapid Deployment

The modular structure of FPSO construction enables faster deployment, shortening the entire production cycle.

4. Multiple Offloading Options

FPSOs offer a variety of offloading alternatives, including shuttle tankers and pipelines, providing operators greater flexibility in transferring hydrocarbons to refineries.

Challenges and Considerations for Floating Production Storage and Offloading Units

1. Harsh Environmental Conditions

FPSOs must be able to survive adverse weather conditions, which necessitates robust engineering to assure stability and safety.

2. Maintenance and Operations

Because of their distant locations and exposure to harsh environments, FPSO maintenance and operations can be complicated.

3. Regulatory Compliance

Environmental and safety requirements must be strictly followed to ensure responsible hydrocarbon extraction and prevent environmental harm.

Technological Advancements in Floating Production Storage and Offloading Units

As the demand for offshore oil and gas production continues to rise, the Floating Production Storage and Offloading (FPSO) units have undergone significant technological advancements. These innovations aim to enhance efficiency, safety, and environmental sustainability in the exploration and extraction of hydrocarbons.

1. Digitalization and Data Integration

One of the most transformative developments in FPSO technology is the integration of digitalization and data analytics. Advanced sensors and monitoring systems are now embedded throughout FPSO units, providing real-time data on various operational parameters. This data-driven approach enables proactive maintenance, optimizing performance, and minimizing downtime.

2. Enhanced Subsea Processing

Recent advancements in subsea processing technologies have allowed FPSOs to process hydrocarbons at the seabed before transporting them to the surface. This reduces the need for complex topside facilities, lowers capital expenditure, and improves overall system efficiency. Subsea boosting and separation systems contribute to increased oil recovery rates and reduced environmental impact.

3. Automation and Robotics

Routine maintenance and inspection tasks on FPSO units have been transformed by the use of automation and robotics. For subsea inspections, remotely operated vehicles (ROVs) are used, while drones are used for aerial surveys. These technologies improve safety by reducing human exposure to potentially hazardous conditions and decreasing downtime associated with maintenance procedures.

4. Advanced Positioning and Mooring Systems

FPSOs today use modern positioning and mooring technologies to ensure stability and optimal location in tough offshore settings. FPSOs can retain precise locations even in harsh weather conditions because to dynamic positioning technology combined with thrusters and anchoring devices.

5. Flexible Riser Systems

FPSOs currently have adjustable riser systems to accommodate changing sea conditions and reservoir characteristics. These systems accommodate the dynamic movement of the vessel, reducing stress on risers and enhancing overall system reliability. Flexible risers also contribute to the adaptability of FPSOs in diverse operational scenarios.

6. Enhanced Safety and Emergency Response Systems

Advances in safety technologies have resulted in more effective emergency response systems for FPSO units. Fire detection and suppression systems, as well as advanced emergency shutdown systems, contribute to the overall safety of the facility. Additionally, enhanced personnel training programs utilizing virtual reality simulations further improve emergency preparedness.

7. Environmental Monitoring and Compliance

Stringent environmental regulations have driven advancements in environmental monitoring systems on FPSO units. Continuous monitoring of emissions, discharge, and oil spill detection systems ensures compliance with environmental standards. Innovative technologies contribute to minimizing the environmental footprint of FPSO operations.

8. Modular Design and Standardization

Modern FPSO units are often designed with modular components, allowing for standardized fabrication and quicker deployment. This modular approach improves project timelines and reduces construction costs. Standardized components also facilitate easier upgrades and modifications as technology evolves.

9. Materials and Coating Innovations

Advancements in materials science and coatings have enhanced the durability and corrosion resistance of FPSO structures. The use of high-strength metals, corrosion-resistant materials, and sophisticated coatings all contribute to longer asset life and lower maintenance costs.

10. Remote Operations and Connectivity

Remote monitoring and management of FPSO units is now possible because of the integration of satellite communication systems and modern connectivity options. This feature improves operating efficiency, enables real-time decision-making, and eliminates the need for on-site staff, particularly in difficult or remote situations.

Conclusion

The offshore energy extraction has been transformed by floating production storage and offloading units, which provide a flexible, efficient, and cost-effective solution for hydrocarbon extraction in difficult settings. As these developments progress, FPSO units will play a critical role in satisfying the world’s expanding need for hydrocarbons while following to increasingly rigorous environmental regulations.