-1-1024x576.jpg)

ESIM-FFA2 Fracturing and Acidizing Simulator

- Parameters can be set parameter freely, such as formation information, fracture fluid parameter etc.

- Different well type can be chosen for fracturing operation, such as vertical well, deviated well, horizontal well, etc.

- Parameter display is the same as that on site, such as curve display of pressure, flow rate, etc.

- Calculate important parameters such as working condition, pressure and flow rate at real time.

- Important data change trend can be displayed in the form of curves.

- Data playback function enables students to view data curves of any parameter during operation.

1. Introduction

ESIM-FFA2 fracturing and acidizing simulation training system is developed by Southwest Petroleum University and Chengdu Esimtech Petroleum Equipment Simulation Technology Exploitation Co,Ltd.It is a system with advanced technology and complete functions,which can satisfy the training requirements of the oilfield companies.This system is a combination of petroleum engineering,computer technology and virtual reality technology.It contains various training modules such as training on fracturing devices,fracturing design,fracturing construction,fracturing process,acidizing fracturing,fracturing accidents analyzing,etc.It is mainly used for training new personnel,fracturing and acidizing workers and technicians.Through the training and testing of this system,students can master the operational method of the devices,and learn the process of fracturing and acidizing and common treatment of fracturing accidents.

The system adopts mathematical models to simulate various parameters in the process of fracturing and acidizing,such as pressure,flow rate,etc.It can also reflect the relationship between these parameters to reach the same effect of the real operation.Virtual reality technology is used to construct the lifelike environment;synchronic 3D animation,large size projecting system,and the highly emulated sound effect makes up an immersive environment for the users.

The system consists of fracturing truck console,blender truck console,device models which linked with fracturing site,graphics system and other accessories.The operations of these consoles are the same as the real equipment.All the layout of the panels,operation methods,and parameter display is exactly the same as the real equipment.Hardware devices adopt the industrial PLC,which ensures the stability of the equipment.The system has the advantage of low input and maintenance cost with no security risk.

2. System Component

2.1 Major Hardware

(1)Local fracturing truck console: controlling and parameter displaying on fracturing truck console is the same as the real equipment. It can simulate operations as starting, shutting down, selecting lever and motor rotary rate adjusting, and display important parameters such as motor rotary rate, oil pressure, oil temperature, pump pressure, flow rate, etc

|

|

Local fracturing truck console:made of metal,industrial control devices with long lifespan and high stability. |

(2)Remote fracturing truck console:controlling and parameter displaying on fracturing truck console is the same as the real equipment.It can simulate operations as starting,shutting down,selecting lever and motor rotary rate adjusting,and display important parameters such as motor rotary rate,oil pressure,oil temperature,pump pressure,flow rate,etc.

|

|

Remote fracturing truck console:made of metal,industrial control devices with long lifespan and high stability. |

(3)Local blender truck console:controlling and parameter displaying on blender truck console is the same as the real equipment.It can simulate operations of blender truck start and stop,sand addition control,liquid addition control,dry addition control,discharge control,etc.Important information will be displaced when student doing operations on the simulator,such as chief inhalation oil pressure,auxiliary inhalation oil pressure,generator oil position,sand transportation oil pressure,generator speed,blending oil pressure,fan oil pressure,hydraulic oil temperature,liquid addition oil pressure,4#sand displacement,4#sand total volume,8#sand displacement,8#sand total volume,dry addition displacement,dry addition volume,1#liquid addition displacement,1#liquid addition volume,2#liquid addition displacement,2#liquid ESIM-FFA2 Fracturing and Acidizing Simulation Training System addition volume,3#liquid addition displacement,3#liquid addition volume,displacement volume,pressure,volume,sand ratio and density,etc.

|

|

Local blender truck console:made of metal,industrial control devices with long lifespan and high stability. |

(4)Remote blender truck console:controlling and parameter displaying on blender truck console is the same as the real equipment.It can simulate operations of blender truck start and stop,sand addition control,liquid addition control,dry addition control,discharge control,etc.Important information will be displaced when student doing operations on the simulator,such as chief inhalation oil pressure,auxiliary inhalation oil pressure,generator oil position,sand transportation oil pressure,generator speed,blending oil pressure,fan oil pressure,hydraulic oil temperature,liquid addition oil pressure,4#sand displacement,4#sand total volume,8#sand displacement,8#sand total volume,dry addition displacement,dry addition volume,1#liquid addition displacement,1#liquid addition volume,2#liquid addition displacement,2#liquid addition volume,3#liquid addition displacement,3#liquid addition volume,displacement volume,pressure,volume,sand ratio and density,etc.

|

|

Remote blender truck console:made of metal,industrial control devices with long lifespan and high stability. |

(5)Liquid storage tanks and tank manifold models:three steel liquid storage tank models used to simulate the tanks in fracturing and acidizing site,simulating storage of active water,fracturing ESIM-FFA2 Fracturing and Acidizing Simulation Training System fluids and crosslinked fluid.The tanks manifold model simulates manifold on real site.The status of valves on the manifolds is sent to parameter computer by sensors.

|

|

Liquid storage tanks and tank manifolds:made of metal and plastic,with industrial sensors. |

(6)Blender truck model:this model displays the inner lines and the status of the valves.The status of valves on the manifolds is sent to parameter computer by sensors.

|

|

Blender truck model:made of metal and plastic,with industrial sensors. |

(7)High-and low-pressure manifold model:this is used to simulate the connection and status of the high-and low-pressure manifolds.It enables students to connect the manifold safely and directly under different conditions of various technologies.The status of valves on the manifolds is sent to parameter computer by sensors.

|

|

High-and low-pressure manifold model:made of metal and plastic,with industrial sensors. |

(8)Sand concentrator and wax bead manifold model:this is used to simulate the lines and valve status of sand concentrator and wax bead manifold.The status of valves on the manifolds is sent to parameter computer by sensors.

|

|

Sand concentrator and wax bead manifold model:made of metal and plastic,with industrial sensors. |

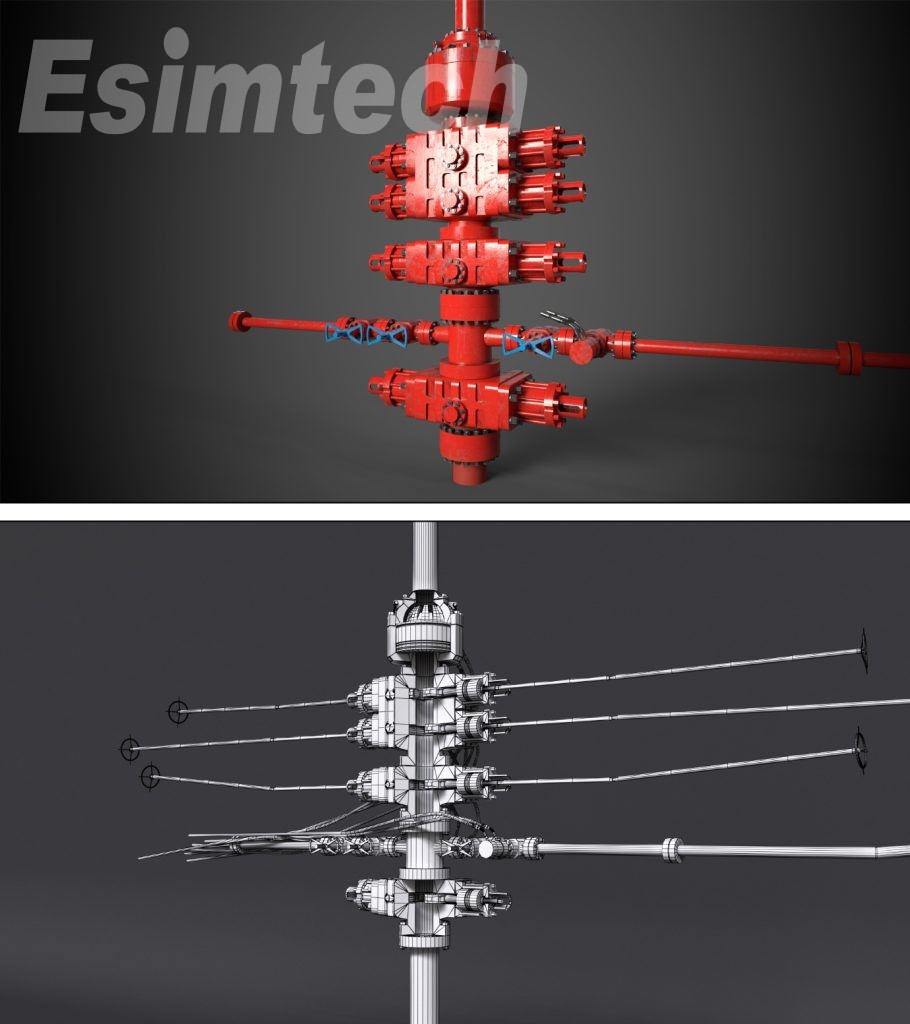

(9)Fracturing wellhead model:used to simulate the status of fracturing wellhead and the liquid flow trend.User can complete various operations through the status of the valves on the wellhead model.The status of valves on the manifolds is sent to parameter computer by sensors.

|

|

Fracturing wellhead:made of metal and plastic,with industrial sensors. |

(10)Instructor station, computer cabinet, parameter computer, master control computer, graphic computer, switchboard, sound effect system and print.

(11)Display system adopts LED screen display system.

|

|

Large sizeLEDscreen full color display system • The 3D animation is displayed on LED true color display screen after process by professional graphics processor. • LEDP2.5 screen, resolution:1920*1080 • LED screen size: 5400mm(wide)*3215mm(high) (The ultimate installation size and resolution will be depended on installation environment) |

2.2 System Software

2.2.1 Master Control Software

-

Instructor console software module

-

System self-checking module

-

Knob correction module

-

System setting module

-

Students management module

-

Record management module

-

Snapshot management module

2.2.2 Parameter software

-

Parameter computer control software module

-

Exercise operation module

-

Curve display module

-

Manifold simulation module

2.2.3 Graphics software

-

3D scene display of fracturing surface software module

-

3D scene display of fracturing downhole software module

-

Animation video playing of fracturing module

3. SystemFunction

3.1 Functions and Features

(1) The system is designed according to the prototype of real site equipment. The appearance, line connection and operation method are the same as real devices.

(2) Fracturing truck console and blender truck console are the same as the real equipment in operation methods, which enable students to master the skill of operating real devices and the treatment of emergency accidents.

(3) Parameters can be set freely. Instructor can set various parameter freely, such as formation information fracture devices information, fracture tool information, fracture fluid parameter etc. Instructor can also set the parameters based on the condition of a real well and chosen devices so that the training is more realistic as training on a real well.

(4) Different well type can be chosen for fracturing operation, including: vertical well, deviated well, horizontal well and horizontal branched well.

(5) The parameter display is the same as that on real site, including curve display of pressure, flow rate and proppant concentration and other important parameter display. It can present the construction directly, which cultivate students the ability of judging downhole condition, treating emergency and handling troubles.

(6) To cultivate students’ safety awareness, there will be voice prompt during operation.

(7) The system can calculate important parameters such as equipment working condition, pressure and flow rate at real time according to students’ operation based on physical mathematical models.

(8) The 3D animation simulates the visualization of real environment, also displays downhole conditions, device motions and working theories of the devices.

(9) Sound effect system may simulate the noises of diesel engine, pump, fracturing truck, blender truck, which make the training environment immersive.

(10) Complete scoring and testing system can assess student’s operations, find their mistakes, record and print their operation conditions.

(11) Complete students’ information managing function managing student’s information, operation items and operation scores.

(12) Important data change trend can be displayed in the form of curves to cultivate students’ skill of judging under well condition and accidents through curves.

(13) Data playback function enables students to view data curves of any parameter during operation.

(14) The system also has the function of report and curves printing

3.2 Training Project

(1) Blender truck operation

(2) Fracturing tuck local control operation

(3) Fracturing tuck remote control operation

(4) Fracturing devices configuring

(5) Fracturing devices connecting

(6) Fracturing string configuring

(7) Fracturing fluid volume design

(8) Proppant volumedesign

(9) Circulating operation

(10)Pressure testing operation

(11) Pushing testing operation

(12) Fracturing operation

(13) Adding sand operation

(14) Displacing operation

(15) Conventional fracturing operation

(16) Sliding sleeve separated fracturing operation

(17) Ball sealer selective fracturing operation

(18) Wax bead selective fracturing operation

(19) Limited entry fracturing operation

(20) Taking off sand fromendfracturing operation

(21) Staged fracturing of horizontal well

(22) Staged fracturing of horizontal well by pumping bridge plug

(23) Staged fracturing of horizontal well by packer

(24) Low pressure acid displacement

(25) Setting packer

(26) Highpressure pump injection

(27) Acid fracturing operation

(28) Acid pickling display

(29) Matrix acidizing display

(30) Standard fracturing display

(31) Standard acidizing display

(32) Process display of fracture generating

(33) Process display of fracture extension

(34) Fracturing failure

(35) Fracturing from one stratum to another

(36) Sandplugging

(37) String falling off

(38) Pumppressure surge

4. Technical Parameters and Operational Environment

4.1 Technical Parameters

(1)Power supply: 220V/50Hz AC

(2)Power consumption: <6000W

4.2 Operational Environment

(1) Area: >=13*9m

(2) Separate equipment power supply fromlightpower supply

(3) Working temperature: 0℃~30℃

(4) Relative humidity: <90%

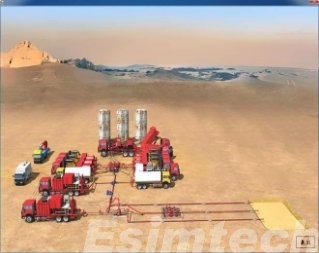

5. System whole layout and program interface

Figure 1 System whole layout

(1) Master control program interface

(2) Parameter program interface

Figure 2 Typical program running interface

Our Strength

- Preciseness

- Precise mathematical and physical model

- Reliability

- Stable and reliable software and hardware

- Service

- Timely and considerate after-sale service

F&Q

- Do you have any certifications?

Esimtech drilling and well control simulator has been approved by IWCF and IADC.

Since its establishment, Esimtech has obtained a series of independent intellectual property rights, including invention patents in China and abroad.

Esimtech was granted as “High-tech Enterprise”, and has been awarded the third prize of “Science and Technology Progress”.

Esimtech has also obtained the certificates of ISO 9001, ISO14001 and ISO45001.

- Do you have simulators simulating offshore drilling platforms?

Esimtech provides drilling and well control simulators with offshore platform simulation.

- Is there a complete instruction for use if I ordered?

There will be completely operational instruction and maintenance instruction along with the package.

- How would I get the simulators if I ordered?

The package will be shipped to the customer’s facility. If necessary, Esimtech provides onsite installation and training services.