Acid Stimulation in Oil Wells: Types and Applications

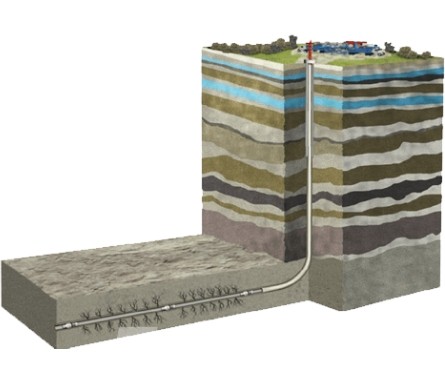

Acid stimulation is a well stimulation treatment widely utilized in the oil and gas industry. With the objective of increasing oil and gas reservoir productivity, this process involves acid injection in the wellbore to dissolve rock structures or eliminate formation damage. In this article, we cover the types, uses, and best practices of acid stimulation of oil wells with the intention of optimizing production for operators.

What is Acid Stimulation?

Acid stimulation is a well stimulation technique used in the oil and gas industry to enhance the productivity of a well by improving the flow of hydrocarbons from the reservoir to the surface. This process involves injecting specially formulated acids into the wellbore to dissolve formation damage, clean out debris, or increase permeability in the surrounding rock. The goal is to restore or improve the natural flow pathways within the reservoir that may have been blocked or restricted during drilling, completion, or production operations.

The technique is especially effective in carbonate formations, where acid can dissolve limestone or dolomite, creating new flow channels. In sandstone formations, acid stimulation targets the removal of clays, fines, or drilling fluid residues that reduce permeability. Unlike hydraulic fracturing, acid stimulation doesn’t always require breaking the rock; in many cases, it works by simply clearing obstructions and enhancing existing pore spaces.

By removing these blockages or altering the rock structure, acid stimulation of oil wells can lead to a significant increase in oil and gas production. It’s a cost-effective method for rejuvenating declining wells, improving initial production rates, and extending the operational life of the reservoir.

Types of Acid Stimulation Techniques

Acid stimulation in oil and gas production can be classified into two general categories: matrix acidizing and fracture acidizing. Both of these techniques are employed to increase the flow of hydrocarbons, although they utilize various means, pressures, and formations.

Matrix Acidizing

Matrix acidizing is performed at pressures below the reservoir fracture pressure. It is used to eliminate the near-wellbore damage by dissolving formation damage in the form of scale, drilling mud, clay particles, or organic deposits that restrict the flow of fluids. In carbonate reservoirs, acids like hydrochloric acid react with the rock to reopen natural pore space, increasing permeability. When sandstone formations are being treated, a mixture of hydrochloric and hydrofluoric acid—otherwise referred to as mud acid—is used to dissolve clays and silicates.

Matrix acidizing is typically used in already producing wells with declining flow rates due to near-wellbore damage. It’s a relatively low-cost and moderately low-risk method of boosting production without altering the reservoir structure.

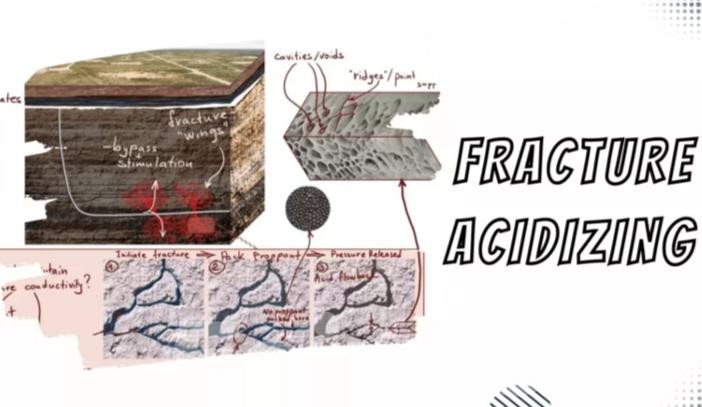

Fracture Acidizing

Fracture acidizing, or acid fracturing, is high-pressure pumping of acid—above the formation fracture gradient—to create small fractures in the rock. Once the formation is fractured, the acid etches the fracture faces and creates permanent flow channels after the release of pressure and the rock’s partial closing.

This method is particularly successful in carbonate reservoirs where the acid can still react with the rock deep back into the fracture network. The etched conduits allow for much greater flow of hydrocarbons compared to matrix acidizing.

Fracture acidizing is frequently used in tight formations where natural permeability is too low to maintain economic production without stimulation.

Both of these are practical oil well stimulation methods, and the choice between them depends on reservoir characteristics, formation type, and production goals.

Applications of Acid Stimulation of Oil Wells

Acid stimulation of oil wells is a crucial operation for the enhancement of hydrocarbon recovery and extension of the productive life of a reservoir. Its applications extend from removal of damage in recently drilled wells to performance enhancement in mature fields. The most critical two areas where acid stimulation is employed are reservoir management and enhanced oil recovery (EOR).

Reservoir Management

Formation damage may severely limit well productivity in newly discovered as well as in mature reservoirs. Most often, the damage is caused by drilling, cementing, or invasion of the formation fluid. Acid stimulation is used as a remedial treatment to flush out the near-wellbore area trash, break down the plugs, and regain native permeability.

Operators use matrix acidizing in production wells to dissolve scale, clay, or organic buildup that accumulates with time. The removal of these blockages by acid stimulation avoids a reduction in production rates, relieves pressure build-up, and optimizes reservoir drainage.

Stimulation is occasionally performed preemptively as part of routine maintenance for the sake of long-term well condition and effective production.

Enhanced Oil Recovery (EOR)

In older or mature reservoirs, acid stimulation is typically applied in combination with other well stimulation and EOR methods to raise recovery factors. Fracture acidizing, for instance, is used to stimulate penetrated or tight zones previously uneconomical to produce.

By increasing the permeability of low-permeability reservoirs, acidizing opens new pathways for trapped hydrocarbons, significantly improving sweep efficiency. This is especially useful in carbonate reservoirs where the acid-rock reaction can penetrate deep into the reservoir.

As part of total EOR schemes, acid stimulation can restore old wells, delay abandonment, and mobilize reserves that are otherwise unproducible.

In general, acid stimulation is a good and effective technique that allows for short-term production goals as well as long-term reservoir enhancement.

Common Acids Used in Stimulation

The success of acid stimulation in gas and oil wells depends to a great extent on determining the right type of acid to be applied to the specific formation and treatment application. Different kinds of rocks—e.g., sandstones and carbonates—react differently to different acids. The most common acids utilized in oil well stimulation are:

- Hydrochloric Acid (HCl): Hydrochloric acid is the most widely used acid in acid stimulation and is particularly very effective in carbonate reservoirs like limestone and dolomite. Hydrochloric acid has a fast reaction with carbonate rock and dissolves it to create flow channels and enhance permeability. Volumes typically vary from 5% to 28%, based on the treatment.

- Hydrofluoric Acid (HF): Hydrofluoric acid has overall use in sandstone reservoirs where clays and siliceous materials are involved. HF is generally combined with HCl to form mud acid, which dissolves silicates, aluminosilicates, and clays that cause formation damage. This mixture is highly effective for deep cleaning near-wellbore intervals in sandstone reservoirs.

- Organic Acids: Organic acids such as formic acid and acetic acid are used in hot wells or where a slower rate of reaction is needed. They are less corrosive and produce fewer reaction byproducts than mineral acids and therefore are ideal for gentle formations and harsh downhole conditions.

- Chelating Agents and Blends to Order: Specialty acid blends or chelating agents are used in specific applications to attack a specific type of scale or mineral deposit. They are typically used in complex wells or where there is environmental legislation that will not allow the use of harsh mineral acids.

The right acid ensures optimal rock dissolution, minimal damage, and improved hydrocarbon flow.

Best Practices for Effective Acid Stimulation

For the best success of acid stimulation on oil wells, a well-planned and engineered treatment is necessary. Through good planning, execution, and analysis, the success of both matrix acidizing and fracture acidizing treatments can be significantly improved.

1. Pre-Job Planning and Well Diagnostics

Before any stimulation, it’s critical to perform a complete reservoir and well analysis. This includes the examination of well logs, production history, formation properties, and previous treatment records. The identification of the type and extent of formation damage or flow restrictions helps in choosing the most appropriate acid type and treatment design.

- Acidizing Simulation

Acidizing simulation, such as fracturing acidizing simulator, is a critical component of the planning process. Using specialized software, engineers can model how the acid will behave once it is in the formation. The simulations predict acid penetration depth, reaction rates, temperature effects, and potential fluid incompatibility issues. By modeling different treatment scenarios, operators can optimize acid volumes, injection rates, and contact time—reducing the potential for underperformance or formation damage.

3. Zonal Isolation and Fluid Placement

Effective zonal isolation using packers or mechanical diverters ensures that acid is positioned precisely in the target zone. Efficient fluid placement increases effectiveness and minimizes the risk of causing damage to other parts of the formation or wellbore.

4. Post-Treatment Evaluation

After stimulation, production data, pressure responses, and well logs need to be analyzed in order to determine treatment success. This kind of feedback is important in enhancing future stimulation designs.

5. Safety and Environmental Compliance

Acid handling requires strict safety procedures and environmental precautions. Training, protective equipment, and safe disposal practices are necessary for safe operations.

Following these best practices—especially the utilization of acidizing simulation—ensures effective and economically successful acid stimulation of oil wells.

Acid stimulation is an important well stimulation technique employed to enhance oil well production by removing formation damage and enhancing permeability. Regardless of through matrix acidizing or fracture acidizing, the process plays a central role in reservoir management and EOR. Production efficiency can be optimized and well life extended by operators practicing best practices and employing the best acids.

To learn more about oil well stimulation techniques and acid stimulation of oil wells, consult the expertise from the industry to refine your well treatment planning.