Acidization of Oil and Gas Wells: Techniques, Benefits, and Risks Explained

Maximizing the productivity of wells is the gateway to profitability and sustainability in competitive oil and gas operations. One of the most effective means of achieving this is acidization of oil and gas wells. By applying chemical treatments judiciously, operators can restore and enhance the flow of hydrocarbons from reservoirs, even in damaged or older wells. This article summarizes the techniques, benefits, and risks of oil well acidizing to help guide industry stakeholders and practitioners in making sound decisions based on best practices and scientific information.

What Is Acidization of Oil and Gas Wells?

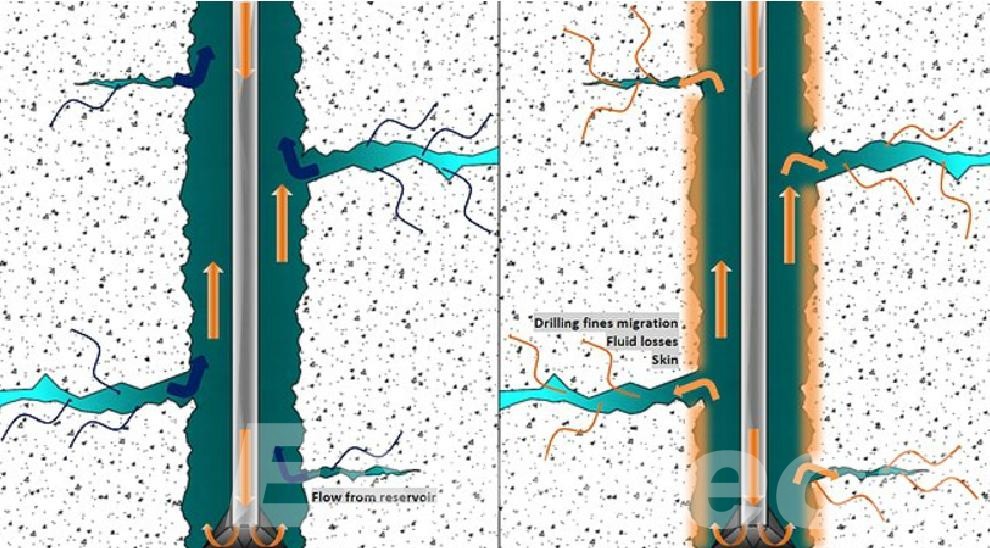

Oil and gas well acidizing is a method of well stimulation applied in a specialized way to stimulate hydrocarbon flow from the reservoir into the wellbore. Wells gradually become less productive due to buildups of scale, fines, or destruction of the original pores in the formation. Acidizing addresses this by injecting selected acids into the well, which attack the rock to dissolve obstructions and enhance permeability.

There are two major objectives of oil well acidizing:

- Enhancing Well Productivity: Dissolving the damage to the formation that plugs up the natural pathways of oil and gas.

- Enhancing Reservoir Performance: Increasing the capacity of the reservoir to flow in order to enhance hydrocarbon recovery.

This treatment is a general treatment applied both to sandstone and carbonate reservoirs. Carbonate reservoirs generally respond well to hydrochloric acid (HCl), while sandstones are treated with a combination of hydrochloric and hydrofluoric acids (HCl + HF). Acidization has the potential to boost production rates considerably by treating selectively the damaged zones without drilling new wells, thus proving to be an economical well life extension and maintenance process.

Techniques of Oil Well Acidization

Oil well acidizing employs multiple reservoir stimulation techniques, each tailored to specific types of formations and well conditions. The ultimate goal is the improvement in permeability and restoration of hydrocarbon flow at minimum risk to the wellbore and adjacent formation.

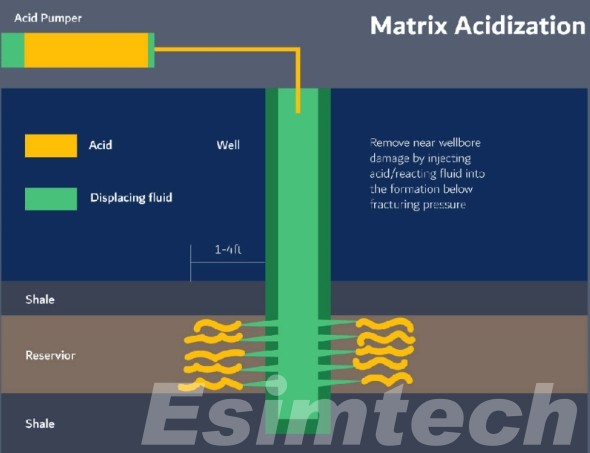

Matrix Acidizing

Matrix acidizing is a treated process where acid is injected below the fracture pressure of the formation. This process consists of dissolving scale, fines, and other constrictions within the pore spaces of the reservoir rock.

- Process: Acid is injected slowly to penetrate the formation without fracturing.

- Typical Applications: Hydrochloric acid (HCl) is applied for treatment of carbonate structures, while sandstone structures could require both HCl and hydrofluoric acid.

- Benefits: Maximizes the productivity of wells by maximizing the permeability while not compromising the structural integrity of the reservoir.

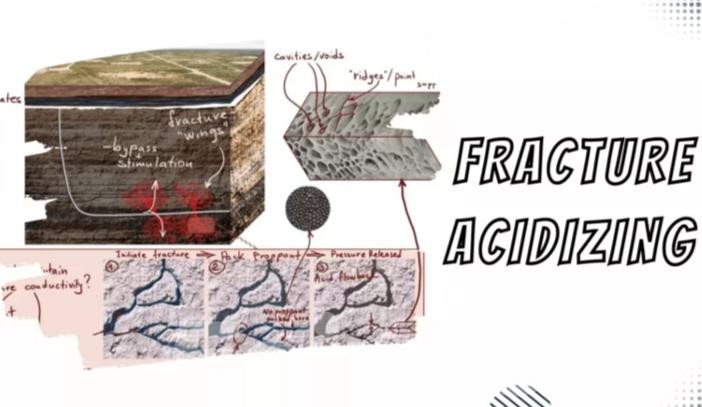

Fracture Acidizing

Fracture acidizing, or acid fracturing, involves the injection of acid above the fracture pressure of the formation. This creates new fractures or prolongs old ones, allowing hydrocarbons to flow more efficiently towards the wellbore.

- Procedure: High-pressure acid injection, commonly followed by a proppant that allows fractures not to close.

- Applicable to: Tight or low-permeability reservoirs where there are insufficient natural flow paths.

- Advantages: Increases effective reservoir contact area to enhance hydrocarbon recovery in hard-to-produce intervals.

Advanced Techniques

Modern oil well acidizing has evolved to include advanced methods that optimize efficiency and reduce risks:

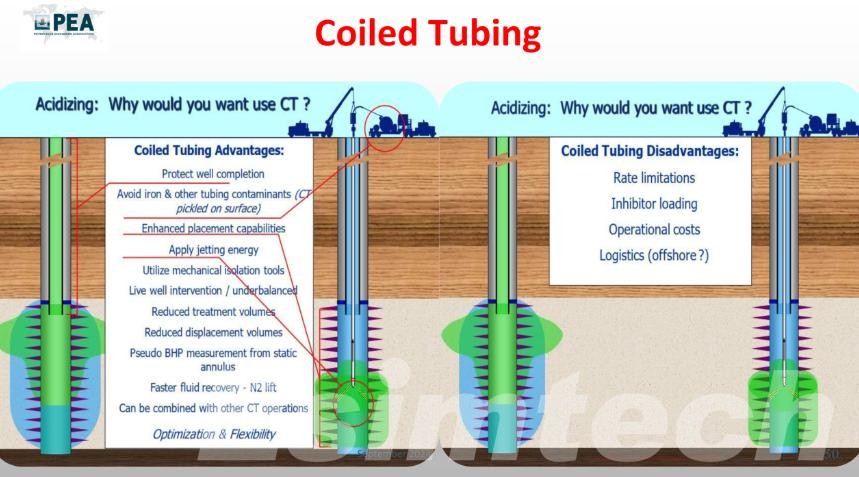

- Coiled Tubing Acidizing: Provides precise placement of acid in horizontal or highly deviated wells.

- Pulsed Acidizing: Uses pressure pulses to enhance acid penetration and reduce consumption.

- Simulation-Driven Acidizing: Employs reservoir models to determine optimal acid type, concentration, and injection strategy, minimizing formation damage and improving safety.

These techniques allow operators to tailor oil well acidizing to the specific conditions of each well, maximizing productivity while minimizing environmental and operational risks.

Benefits of Oil Well Acidization

Oil well acidizing offers significant advantages in terms of enhanced well performance, longer operating life, and total hydrocarbon recovery. The benefits are both short and long term and therefore the technique is widely sought after in the oil and gas industry.

- Increased Production Rates

By cracking open formation damage, scale, and plugged pores, acidization dissolves limitations of natural flow channels, allowing the hydrocarbons to move more freely to the wellbore. Well production tends to increase considerably for acid-treated wells.

- Cost-Effective Enhancement

Acidizing oil and gas wells is a less costly method of increasing output in comparison to new drilling. Acidization maximizes old wells’ productivity at a lower capital expenditure of new drilling projects.

- Extended Well Life

Routine acidizing prevents the accumulation of formation impairment over time, maintaining maximum rates of flow and reducing the likelihood of premature well decline. This ensures long productive life of wells and delays costly interventions.

- Targeted Stimulation

With sophisticated techniques and computer-designed simulation, acidizing may be precisely matched to the specific nature of the reservoir. This ensures the acid seeps into most deteriorated sections, optimizing efficiency and reducing excessive chemical consumption.

- Better Reservoir Performance

Beyond the immediate vicinity of the wellbore, acidization has the ability to increase the reservoir’s overall permeability, optimizing hydrocarbon recovery and the ultimate recovery factor from the formation.

In summary, oil well acidizing is a strong and universal method to stimulate production, reduce operational costs, and extend well longevity and hence is a foundation method in modern reservoir management.

Risks of Acidization and How Simulation Improve It?

Acidization of gas and oil wells is a very effective yet complex operation with high risks. A poorly designed job can lead to well damage, ineffective utilization of resources, and environmental and safety hazards. Some of the key operational risks include:

- Corrosion: Hydrochloric and other acids are highly corrosive. Inadequate inhibition or human error during mixing can cause severe damage to wellbore casings, tubing, and surface equipment, resulting in costly repairs or even well failure.

- Ineffective Treatment: Improper rates or pressures during pumping of acid can cause it to react too quickly in high-permeability areas and bypass damaged or lower-permeability sections entirely. The target zone remains untreated, and the operation cost is wasted.

- Formation Damage: Improper acid selection or poor flowback procedures can lead to adverse reaction byproducts (sludge or precipitates) that plug the formation pores more than the original damage.

- Health, Safety, and Environmental (HSE) Hazards: It is inherently dangerous to deal with concentrated acids at the rigsite. Spills, leaks, or uncontrollable release of acid represent very serious risks to personnel and the immediate environment. The disposal of toxic flowback fluid is also a serious issue.

How Operational Training Simulators Mitigate Risk

Here is where advanced operational training simulators can be useful. These high-fidelity computer programs generate a realistic, virtual replica of the well and the entire acidizing operation, enabling crews to prepare and train safely in a no-risk environment.

Simulators improve safety and efficiency by:

- Enhancing Crew Skill and Muscle Memory: The whole procedure, right from pumping and blending to displacement and flowback, may be repeated again and again by the operators, building important muscle memory and, concurrently, getting familiar with the control systems. Mistakes during the high-pressure in-field operation are reduced.

- Drilling Emergency Response: The simulators can model numerous worst-case events, such as a surface blowout, sudden increase in pressure, or failure of the pump. The crews will be taught to execute emergency shutdown (ESD) operations and handle emergencies responsibly and effectively, minimizing panic and injury.

- Procedure and Communication Optimization: The simulation allows groups to validate the pumping schedule and maximize the communication procedures between the pump operator, chemists, and wellsite supervisor. This keeps everyone in line and adheres to the procedure word by word, maximizing the probability of the treatment’s success.

By training on simulators for rigorous training, companies squarely face the human factor of acidizing oil wells. This enhances the experience and expertise of a crew, converting an ordinarily high-risk venture into a well-rehearsed, controlled operation, thereby enhancing safety, protecting assets, and guaranteeing operational excellence.

To Conclude

Oil and gas well acidization is a proven, cost-saving method of well productivity enhancement and hydrocarbon recovery optimization. From fracture to matrix acidizing, and with advanced simulation techniques, operators have the ability to tailor treatments to unique reservoir conditions, maximizing flow while minimizing risks. The treatment not only rejuvenates low-productivity wells but also their working life, obliterates wasteful drilling costs, and optimizes overall reservoir performance. With appropriate planning and execution of oil well acidizing, energy companies can achieve safer, more effective, and more sustainable production, making it a cornerstone method in modern reservoir management.