Chemical Enhanced Oil Recovery to Boosting Production

For centuries, oil has fueled our world’s progress. But as we all know, conventional oil reserves are a finite resource. To meet our energy demands, it’s crucial to maximize oil recovery from existing fields. This is where Chemical Enhanced Oil Recovery (CEOR) steps in.

What is Chemical Enhanced Oil Recovery (CEOR)?

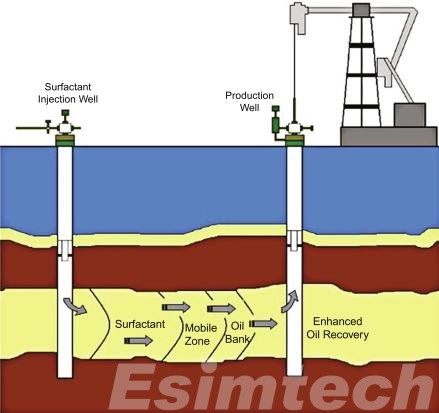

Chemical Enhanced Oil Recovery (CEOR) is an advanced innovative technology aimed at extracting more crude oil from reservoirs that have already been extracted using primary and secondary oil recovery methods. As part of the third recovery phase, the purpose of CEOR is to maximize the extraction of oil that is still trapped in the reservoir after producing more easily recoverable oil.

CEOR involves injecting special chemicals into the reservoir. These chemicals are carefully selected based on the specific characteristics of the reservoir and the type of target oil. The main chemicals used include surfactants, polymers, and alkalis. Each of these chemicals plays a unique role in improving oil recovery:

- Surfactants: Surfactants are compounds that reduce the interfacial tension between oil and water. By reducing this tension, it helps to decompose oil droplets trapped in rock pores, allowing them to flow more freely towards production wells. This process significantly improves the flowability of residual oil.

- Polymer: Polymer is used to increase the viscosity of water injected into the reservoir. This increased viscosity helps to improve the sweep efficiency of the oil recovery process. Thickened water pushes oil more evenly through the reservoir, reducing oil bypass and ensuring more complete displacement.

- Alkali: Sometimes alkali, such as sodium hydroxide, is added to the injection solution to create favorable conditions for surfactants. Alkali reacts with certain components in crude oil to produce natural surfactants, further increasing oil recovery rate. They can also change the wettability of rocks, making them more hydrophilic, which is beneficial for better oil recovery.

The effectiveness of CEOR largely depends on a thorough understanding of reservoir properties, including its geology, fluid characteristics, and existing recovery history. Engineers and scientists conduct extensive reservoir simulations and laboratory experiments to design the most effective chemical formulations and injection strategies for each specific reservoir.

How Does Chemical Enhanced Oil Recovery Boost Production?

Chemical Enhanced Oil Recovery (CEOR) is implemented after primary (natural pressure) and secondary (waterflooding) recovery methods have reached their limits. CEOR achieves this by injecting various chemicals into the reservoir to improve oil displacement efficiency. Next, we will explore how it boosts oil production.

Chemical Enhanced Oil Recovery (CEOR) is A Targeted Approach

CEOR is a specialized subrunch of Enhanced Oil Recovery (EOR) methodologies. It employs specific chemical cocktails to manipulate the properties of reservoir rock and/or crude oil. These chemicals can achieve various objectives, including:

- Interfacial Tension (IFT) Reduction: Imagine oil and water as microscopic spheres. IFT represents the resistance between these spheres. By lowering IFT, CEOR chemicals enable oil droplets to coalesce and flow more readily. This is akin to adding soap to water, which reduces the surface tension and allows water to spread and wet surfaces more easily. In the context of CEOR, lower IFT allows oil to move more freely through the rock pores and towards production wells.

- Enhanced Sweep Efficiency: Sweep efficiency refers to the portion of the reservoir contacted by injected fluids. Specific CEOR chemicals, like polymers, can augment the viscosity of injected water. Imagine water as thin and watery, easily flowing through large channels and bypassing oil trapped in smaller pores. By thickening the injected water with polymers, it acts more like molasses, flowing through both large and small channels, contacting more oil, and displacing a greater volume towards production wells.

- Wettability Alteration: The tendency of water to spread on a rock surface is termed wettability. Most rock formations are naturally water-wet, meaning water preferentially adheres to the rock surface. Oil, on the other hand, clings to itself and tends to occupy the remaining pore space. CEOR chemicals can modify rock wettability to become more oil-repellent, forcing oil out of minute pores and into larger channels for easier extraction. This is like treating a pan to make it non-stick – oil will no longer cling to the rock surface and can flow more freely.

Boosting Production Through Chemical Intervention

By strategically targeting the interplay between oil, water, and rock on a physical and chemical level, CEOR offers several advantages that demonstrably enhance oil production:

- Mobilization of Trapped Oil: Conventional extraction methods often leave significant amounts of oil clinging to rock surfaces or trapped within tight pores. CEOR chemicals can loosen this grip in a few ways. Some chemicals act like surfactants, reducing the interfacial tension between oil and rock, allowing oil to detach from the rock surface. Others may alter the viscosity of the oil itself, making it thinner and easier to flow.

- Improved Sweep Efficiency: As previously discussed, CEOR can optimize the movement of injected fluids within the oil reservoir, ensuring better contact with residual oil. This reduces the risk of bypassing recoverable oil pockets and maximizes extraction.

- Reduced Channeling: During secondary recovery methods like waterflooding, injected fluids can preferentially flow through zones of high permeability, leaving oil behind in less permeable areas. This phenomenon, known as channeling, reduces overall production efficiency. CEOR chemicals can help mitigate channeling by altering the viscosity of the injected fluids or by interacting with the rock matrix to promote a more uniform sweep.

What is Chemical Enhanced Oil Recovery Applied for?

Chemical Enhanced Oil Recovery finds particular application in various scenarios within the oil and gas industry:

- Mature Oil Fields: CEOR is particularly effective in mature oil fields where primary and secondary recovery methods have been exhausted. At this stage, a significant amount of residual oil remains trapped within the reservoir. CEOR techniques, such as reducing oil viscosity, altering rock wettability, or improving sweep efficiency, unlock this trapped potential. These methods extend the productive life of an oil field and maximize ultimate recovery, making CEOR an invaluable tool for mature fields.

- Heavy Oil Reservoirs: Heavy oil deposits, characterized by high viscosity and low mobility, pose significant extraction challenges for conventional methods. CEOR techniques, often used in conjunction with thermal methods like steam flooding and chemical additives, greatly improve the flow properties of heavy oil. This combination enhances production by reducing viscosity and improving the mobility of heavy oil, facilitating its extraction from the reservoir.

- Light Oil Reservoirs: While it may seem counterintuitive, CEOR can also benefit light oil reservoirs. These reservoirs often face specific challenges, such as channeling, where injected fluids flow preferentially through high-permeability zones, leaving behind recoverable oil. CEOR chemicals modify the viscosity of injected fluids or promote more uniform sweep through the rock matrix, addressing these challenges and improving overall recovery efficiency.

- Unconventional Reservoirs: Shale oil and tight oil reserves present unique production challenges due to their low permeability. CEOR techniques, such as hydraulic fracturing combined with specific chemical treatments, help stimulate these formations and enhance hydrocarbon flow. By addressing the low permeability of unconventional reservoirs, CEOR facilitates the extraction of hydrocarbons that would otherwise be inaccessible, significantly boosting production from these challenging reserves.

In summary, CEOR finds critical application across a variety of scenarios within the oil and gas industry, from mature and heavy oil fields to light oil and unconventional reservoirs. Each application leverages the unique capabilities of CEOR to overcome specific challenges, enhancing oil recovery and extending the productive life of oil fields.

Conclusion

Chemical Enhanced Oil Recovery (CEOR) is a well-established technique that leverages the power of chemistry to unlock additional oil reserves. By strategically altering the properties of oil, rock, or injected fluids, CEOR demonstrably enhances production efficiency and contributes to meeting the world’s ongoing demand for hydrocarbons. With continued focus on environmentally conscious formulations and targeted application, CEOR can help bridge the gap between current production and future energy demands.