Cost-Benefit Analysis of Deep Well Snubbing Oil and Gas vs. Traditional Well Intervention

Well intervention is a crucial part of oil and gas operations, maintaining production levels at a steady rate and wells remain operational throughout their lives. Among the most available methods, businesses prefer the choice of conventional well intervention over the more complicated option of deep well snubbing.

Traditional practices, although widely performed, usually involve destroying the well with weighted fluids—a process that may result in formation damage, extended downtime, and additional cost. Snubbing oil and gas operations, however, allows for operations on a pressurized live well without damaging the reservoir and consequently reducing risk and non-productive time.

This element comes closer to deep well snubbing vs. traditional well intervention cost-benefit comparison, where both methods are considered in terms of where each excels, the technical and fiscal trade-offs between each, and how new training technologies such as snubbing simulators, are promoting safer, more efficient operations.

What Is Deep Well Snubbing in Oil and Gas?

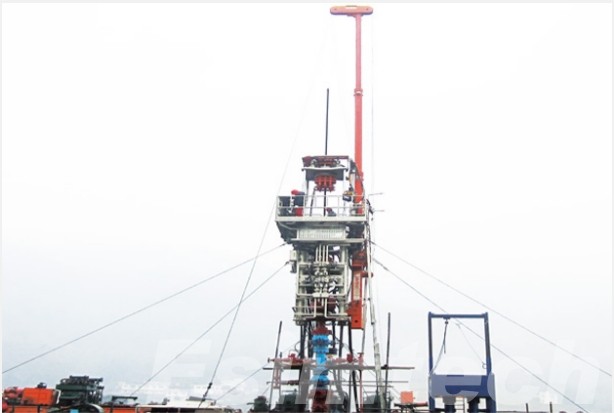

Deep well snubbing is a specialty intervention service technique utilized to perform tubulars—tubing, drill pipe, or casing—inside a pressurized live well. Snubbing operations place access in the wellbore directly under pressure, as opposed to the conventional method of shutting down or killing the well.

The operation relies on a hydraulic snubbing unit to provide the force needed for pulling or pushing pipe against well pressure. The setup ensures well control during execution of activities such as:

- Removal or running of tubing strings

- Downhole maintenance

- Installation or recovery of completion equipment

One of the greatest advantages of snubbing oil and gas operations is that reservoir pressure and production can be preserved while formation damage is prevented. This renders deep well snubbing particularly valuable in HPHT wells or sour gas wells, where standard interventions could threaten safety or induce costly downtime.

By the combination of mechanical expertise and strict operating practices, deep well snubbing allows operators to safely and effectively work over problematic wells, and therefore it is an invaluable tool in modern oil and gas field development.

Traditional Well Intervention: An Overview

Traditional well intervention consists of standard methods used to maintain or enhance oil and gas well production. The processes normally require the well to be killed—that is, pressure the wellbore up with heavy fluids in order to equate formation pressure—before intervention.

Traditional techniques include:

- Workover rigs: Used for major overhauls or replacement of downhole gear.

- Coiled tubing operations: Allows fluid movement and chemical treatments but generally must depressurize the well.

- Wireline operations: Suitable for running logging tools or minor interventions, usually limited to low-pressure situations.

Even though traditional intervention methods are generally utilized due to availability and familiarity, they do have some inherent restrictions:

- More downtime: Killing and re-suspending the well involves non-productive time.

- Formation impact: Heavy fluids can reduce permeability and affect long-term reservoir performance.

- Operational risks: Traditional treatment of sour or high-pressure wells poses safety problems.

By contrast, the application of advanced technology in deep well snubbing is safer and more efficient in cases when the well has to be left live, particularly in the high-pressure, high-temperature, or sour gas environment.

Cost Factors in Deep Well Snubbing Oil and Gas vs Traditional Well Intervention

In evaluating intervention strategy, cost is always a dominant consideration for oil and gas operators. Deep well snubbing and traditional well intervention methods each involve a number of cost factors, however, the cost split and impact may be very unlike.

Deep Well Snubbing Oil and Gas

Deep well snubbing operations require specialized rigs, including hydraulic snubbing units with the ability to operate high-pressure live wells. This takes more initial cost compared to traditional workover rigs. However, the ability to maintain the well live while in operation allows for much less non-productive time (NPT), which can eliminate initial costs.

Labor costs are another factor. Oil and gas operations aside, excluding them demand experienced crews that are well-versed in the procedures of live wells and safety procedures. While training and experienced staff may increase the operational costs, these factors contribute to increased efficiency and less risk of formation damage.

In addition, since the well is not being killed, there will be minimal need for heavy kill fluids. Not only does this reduce material cost but also reduces the risk of reservoir damage, which can affect long-term production and profitability.

Conventional Well Intervention

Conventional methods typically have lower initial equipment costs and less specialist training. But the need to kill the well and circulate large amounts of heavy fluid incurs material and operating costs. Increased downtime from well killing and well restart boosts NPT, potentially leading to significant revenue losses.

Heavy fluid injection formation damage can also have long-term financial impacts, in the sense that it can reduce the overall return on investment.

| Cost Factor | Deep Well Snubbing Oil and Gas | Traditional Well Intervention |

| Equipment Costs | High (specialized snubbing units) | Low (standard workover rigs/coiled tubing) |

| Labor/Training | High (skilled, certified crews) | Moderate (general workover crews) |

| Non-Productive Time (NPT) | Low | High (well killing & restart required) |

| Material Costs | Low (minimal kill fluids) | High (heavy fluids, circulation materials) |

| Reservoir Impact | Low (maintains formation integrity) | Higher (risk of permeability reduction) |

| Long-Term Economic Efficiency | High | Moderate to Low |

By analyzing these factors, it becomes clear that although deep well snubbing carries a higher upfront cost, its advantages in efficiency, safety, and reservoir protection often provide better long-term economic value compared to traditional well intervention.

Is Deep Well Snubbing necessary in Oil and Gas?

The demand for deep well snubbing is highly influenced by well conditions, complexity of operations, and safety requirements. For the scenario of normal wells having low pressure and minimal risk, normal intervention methods can be applied. However, in the majority of modern-day oil and gas operations, especially HPHT wells or sour gas-bearing wells, the dangers involved with conventional interventions might be high.

Snubbing oil and gas operations are the only potential to work on a live well under well control. This is particularly beneficial when closing the well would lead to:

- Protracted downtime and lost production

- More formation damage due to kill fluids

- More safety hazards to crews operating in high-pressure environments

Moreover, the more advanced reservoirs and more innovative production methods become, the more operators end up with more wells where traditional methods can't safely or efficiently get the job done. Deep well snubbing is then not just a convenience—it's oftentimes the best and most economical solution.

Industry trends also identify growing application of snubbing technology in offshore, HPHT, and sour gas fields as further validating its importance in maintaining production while managing operational risk. Deep well snubbing integrated into company intervention planning leads to less non-productive time, improved reservoir protection, and overall better safety, thus a strategic investment rather than an optional approach.

In short, while not every well requires deep well snubbing, for complex, high-risk, or live wells, snubbing oil and gas operations are increasingly becoming a necessity in order to both uphold operational efficiency as well as compliance for safety.

The Use of Oil and Gas Snubbing Simulator

Effective training is a key component in efficient and safe deep well snubbing operations. An oil and gas snubbing simulator provides a controlled, safe environment where operators can be trained in handling live well scenarios before performing actual field work.

These simulators replicate the mechanical and hydraulic reaction of a snubbing unit, exposing trainees to the challenges of pushing or pulling tubulars with high-pressure conditions. Crews have hands-on experience in:

- Well control in true operations

- Responding to unexpected pressure fluctuations

- Coordinating complex maneuvers with the rig crew

The use of a simulator not only enhances technical competence but also significantly reduces the risk of human error, the number one safety concern of snubbing oil and gas operations. Companies applying simulation-based training as a module within their programs demonstrate increased efficiency, reduced operational accidents, and faster crew competency.

Moreover, simulators can be used to pilot new procedures or develop customized training for particular well conditions, a highly valuable tool for operators who aim to optimize safety and productivity in deep well snubbing intervention.

Final Thought

Overall, deep well snubbing is a strategic advantage over traditional well intervention methods, particularly for sour gas wells, high-pressure, high-temperature wells, or other risky wells. By enabling work to be performed on a live well, snubbing oil and gas operations saves time, maintains reservoir integrity, and enhances overall safety. While initial cost is potentially higher, the long-term benefit—greater efficiency, less non-productive time, and less risk of operations—is well worth the investment of deep well snubbing. With the increasing complexity of wells, operators will need to incorporate snubbing methods and simulator training to achieve reliable, safe, and cost-effective interventions.