Drillers Method Used in Well Control: What are the Principles and Why Training is Important for Its Implementation?

Well control is a critical aspect of the oil and gas industry, ensuring the safe and efficient drilling of wells while minimizing the risk of blowouts and other hazardous incidents. Among the various techniques and methods employed in well control, the drillers method stands out as a fundamental approach used by drillers to maintain pressure balance and prevent uncontrolled flow of fluids from the wellbore. In this article, we will explore the drillers method in detail, including its principles, procedures, and the importance of training in its implementation.

Principles of the Drillers Method Used in Well Control

The drillers method, also known as the "wait and weight" approach, is a well-established well control technique used to restore control of a well after an influx of formation fluids is detected. This method relies on several key principles to effectively manage the wellbore pressure and prevent uncontrolled flow.

Influx Detection

The first and most crucial principle is the early detection of an influx or the entry of formation fluids, such as oil, gas, or water, into the wellbore.

Drillers continuously monitor drilling parameters, such as drilling fluid returns, pit gain, and mud logger data, to detect any unexpected changes that may indicate an influx.

Well Closure

When an influx is verified or suspected, the well is immediately closed.

Blowout preventers (BOPs) are actuated to close the wellbore, limiting further influx and assuring the rig crew's safety.

Kill Weight Calculation

The next crucial step is to calculate the drilling mud's required kill weight, which is the weight required to balance the formation pressure and stop the influx.

This estimate takes into account the type of formation, its depth, and the parameters of the drilling mud utilized.

Mud Weight Adjustment

Dense minerals, such as barite or calcium carbonate, are added to the drilling fluid to raise the mud weight. This raises mud density and helps to counteract formation pressure.

The mud weight is adjusted carefully to ensure that it is sufficient to control the well but not so heavy that it causes additional problems.

Controlled Pumping

Pumping of the weighted mud is conducted in a controlled manner. The pump rate is managed to prevent rapid pressure build-up, maintaining a safe and controlled procedure.

The goal is to gradually introduce the weighted mud into the wellbore while monitoring pressure levels.

Continuous Pressure Monitoring

Pressure gauges and monitoring equipment are used to continuously monitor the well's pressure during the procedure.

This real-time data is critical for evaluating the Kill Weight's performance and making any necessary adjustments to retain control.

Resume Drilling

Drilling operations can be restarted cautiously once the well has been brought under control and the influx has been safely controlled.

It is critical to keep the mud weight at a level that keeps the formation pressure under control while the drilling progresses.

These principles of the drillers method underscore the importance of a systematic and methodical approach to well control.

Importance of Training and Preparation for Drillers Method Used in Well Control

When it comes to adopting the drillers method in well control, training and preparation are critical. Comprehensive training and thorough preparation are critical because they have a direct impact on the safety of the rig crew, the integrity of the well, and the success of well control operations.

Safety

The oil and gas industry places a premium on safety. Proper training ensures that rig personnel are adequately equipped to respond to well control problems in a timely and effective manner, reducing the risk of accidents and blowouts. In the event of an inflow, a well-trained workforce is better suited to protect themselves and the environment.

Quick Decision-Making

Time is of the essence in well control. Rig crews must make quick decisions in response to changing conditions. Training provides drillers with the knowledge and skills needed to assess situations, calculate kill weights, and take appropriate actions swiftly and confidently.

Risk Mitigation

Incidents involving well control can have disastrous results, including loss of life, environmental harm, and severe financial losses. Thorough training decreases the possibility of errors and ensures that workers are properly equipped to mitigate hazards.

Efficiency

Drillers who have been properly taught can conduct well control operations more efficiently. This includes calculating kill weights precisely, monitoring mud weight modifications, and controlling pump speeds. Efficient execution reduces downtime and potential equipment damage, resulting in cost savings.

Adaptability

Different wells and formations provide their own set of obstacles. Rig workers must adapt the Drillers Method to different conditions. Training ensures that drillers have a thorough understanding of the method's concepts and that they can apply them to a variety of well conditions.

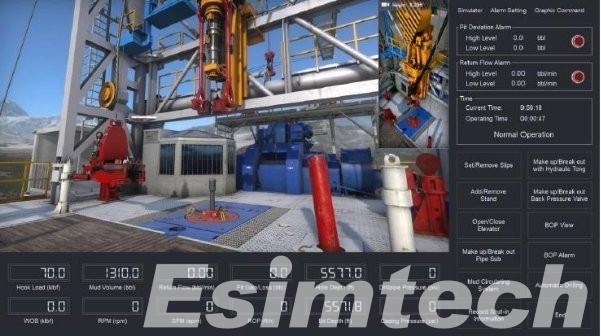

Realistic Simulations

Training often includes realistic simulations and scenarios that mimic well control incidents. These drilling and well control simulators allow drillers to practice the drillers method in a controlled environment, gaining valuable hands-on experience without the risk associated with live operations.

Team Coordination

Well control is a collaborative endeavor. Crew members benefit from effective communication and coordination as a result of training. During key moments, everyone must be on the same page and work effortlessly together.

Regulatory Compliance

To ensure safe drilling operations, many regulatory agencies mandate drilling companies to provide well control training to its workers. Compliance with these regulations is critical for avoiding legal ramifications and maintaining a strong industry reputation.

Continuous Improvement

Well control methods and technologies evolve over time. Regular training keeps drillers up to date on the latest industry practices and innovations, allowing them to efficiently adapt to new problems.

Confidence and Competence

Drillers who have been properly trained have the confidence and expertise to deal with high-pressure situations. During well control incidents, this confidence is critical for maintaining composure and making informed judgments.

Training and preparation are not optional, but rather necessary components of well control, especially when using the Drillers Method. Drilling businesses may guarantee that their workers are well-equipped to respond to well control emergencies, protect lives, the environment, and assets, and maintain the integrity of drilling operations by investing in thorough training programs.

Summary

In the oil and gas industry, the drillers method is an integral component of well control. It demonstrates the significance of proactive, well-planned measures for maintaining pressure balance and preventing wellbore influxes. Training and preparedness are critical to successfully implementing this technology and assuring staff safety and the integrity of drilling operations.