ESIM-FLR2 Land Rig Installation Simulator

- The display of the rig installation whole process enables students to master the installing process.

- Interactive rig model and 3D animation enables students to master the process of derrick and substructure raising and lowering.

- The system enable students to operate hydraulic power equipment and rig controlling system.

- Human-machine interaction provides training and testing of land rig installing process.

- All the levers, meters and gauges, switches are the same as the real equipment.

Land rig installation simulation training system designed by Esimtech combines the technologies of petroleum engineering, computer technology and virtual reality. This system mainly contains 5 parts such as animation demonstration of rig installation; training on lifting and lowering derrick and pedestal; rig virtual assembly; rig simulation operation and electronic graphics.

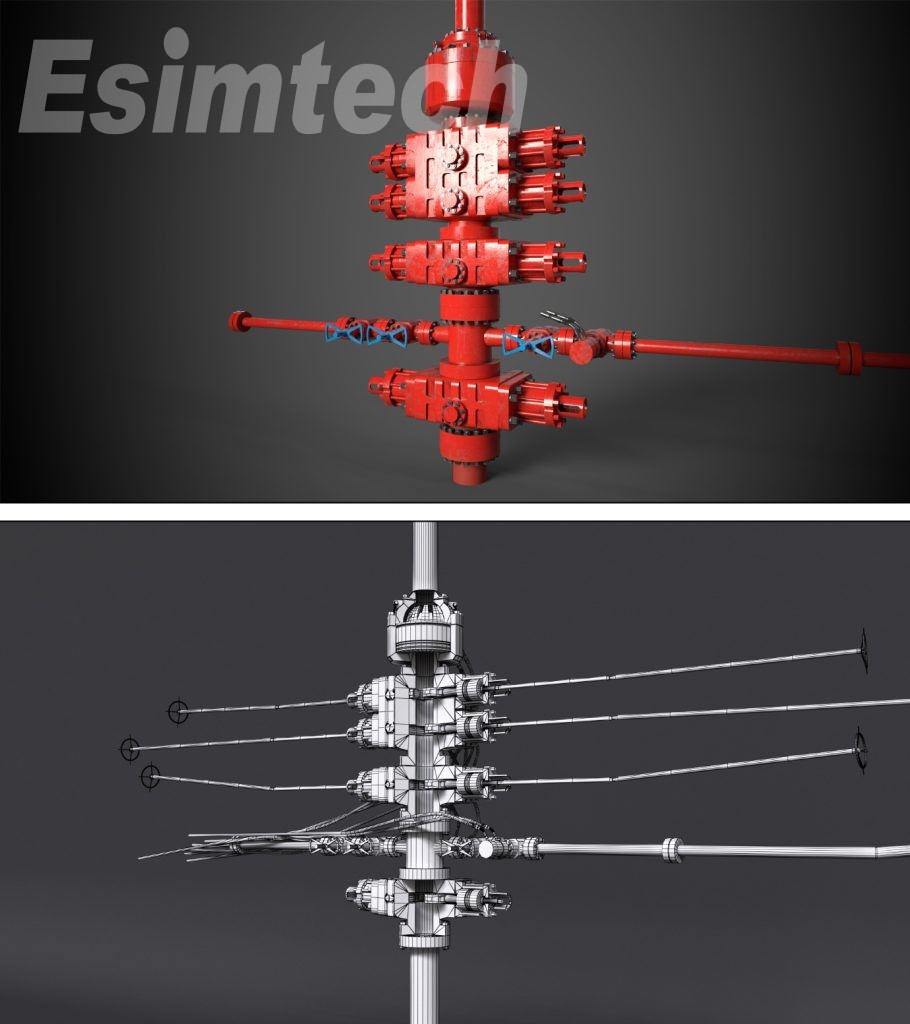

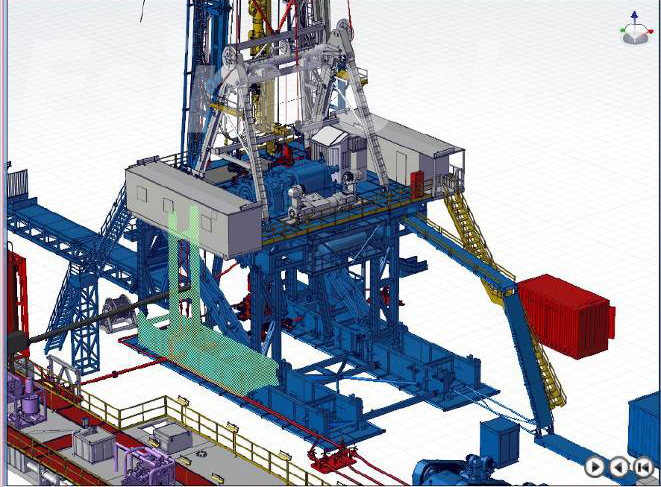

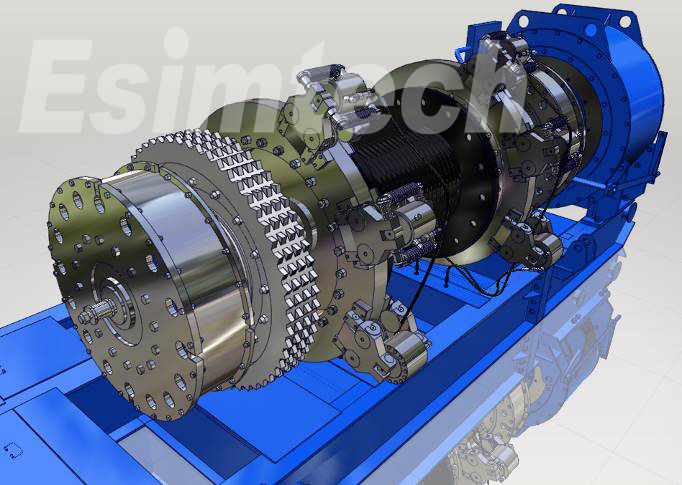

It provides training on the installation process of the land rig and the key points, lifting and lowering process of rig derrick and pedestal, rig tripping in and out, drilling, top drive operation, rig structure, the inner structure of important devices, etc.

System Features

- HD animation presenting procedure of rig installation

- Rig model real-time interaction, 3D animation demonstration

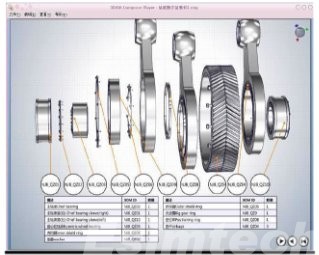

- Detailed electronic graphics displaying rig structure

- Simulating real rig, the same operation as real equipment

- 3D animation simulating real visual environment

Parameters

| Operation voltage: | 220V 50Hz AC |

| Power consumption: | < 6000 Watt |

| Operating temperature | 0-30 degrees Celsius |

| Display resolution: | 1920*960 |

| Average working time between malfunction: | ≥5000 hour |

Training Items

- Rig installing whole process training operation

- Rig installing virtual assembly operation

- Rig equipment structure training operation

- Raising and lowering operation

(1)Derrick raising operation

(2)Pedestal raising operation

(3)Pedestal lowering operation

(4)Derrick lowering operation

Program Interfaces

1. Introduction

Land rig installation simulation training system is developed by Southwest Petroleum University and Chengdu Esimtech Petroleum Equipment Simulation Technology Exploitation Co, Ltd. It is a system with advanced technology and complete functions which can satisfy the training requirements of oilfield companies.

The system is the combination of petroleum engineering technology, computer technology and virtual reality technology. It is mainly used for training new workers, drillers, assistant driller, technicians, and driller supervisor, etc. The system can provide trainings as the land rig installing whole process and notes, land rig derrick and substructure raising and lowering, rig tripping in and out, drilling operation, top drive operation, rig construction, etc.

This system is composed of 4 parts: rig installing whole process animation display module, derrick/substructure raising and lowering training module, rig virtual assembly module and rig simulation operation module. The system adopts high fidelity animation to display the whole process of land rig (exactly as the installing procedure of real land rig). The system uses hardware emulation to train students the operation of derrick and substructure raising and lowering, tripping and drilling. It adopts large quantity of mathematical models to simulation the various parameters, such as pressure, flow rate, torque, drilling rate, etc. The virtual reality technology constructs the vivid environment, combining with the 3D animation displayed through LED screen display, and vivid sound effect makes up an immersive training environment.

The whole system consists of driller console, top dive console, graphics system and other accessories. The layout of the panels, operation methods, parameter displaying is the same as the real equipment. Hardware devices are constructed by industrial PLC, which ensures the stability of the system. The system has the advantage of low input and maintenance cost, with no security risk.

2. System Component

2.1 Major Hardware

The controlling and parameter displaying of driller console is the same as the real equipment. It can simulate raising and lowering of drawworks and speed regulation of mud pumps. It can display parameters as WOB, top drive rotary rate, standpipe pressure, casing pressure, torque, in flow, out flow percentage, well depth, bit position, top drive height, footage, drill time, drilling rate, drill pipe speed, well bottom pressure, formation pressure, etc. This console is made of metal; simulating ZJ70D DC electric rig, with disc brake; supporting top drive operations; integrated with parameter display station.

2. Top drive console can simulate various operations, linkage and controlling of top drive, including IBOP, turret lock, links rotate, links tilt, backup tong, operation (drill, spin, torque), direction (reverse, stop, forward), etc. It simulates the top dive 70 manufactured by Beijing Petroleum Machinery Factory, all metal construction.

Display system

|

|

• Presenting simulated 3D animation on LED screen full color display after process by professional graphics workstation. • LED P2.5 screen; Resolution: 1920*1080 • Screen size: 5400mm(wide)*3215mm(high) (The ultimate installation size and resolution will be depended on installation environment) |

2.2 System Software

2.2.1 Master Control Software

-

Rig installing whole process displaying module

-

Rig installing derrick and substructure raising and lowering training module

-

Rig virtual assembly module

-

Rigtripping/drilling operation module

2.2.2 Graphics Software

-

Top drive-based 3D scene display software module

-

Rig installing whole process 3D animation display module

3. System Function

3.1 Functions and Features

(1) The system can display the whole process of rig installing and notes through high fidelity animation, which makes students master the installing process without going to thesite.

(2) The system enables students to operate hydraulic power equipment and rig controlling system. Interactive rig model and 3D animation enables students to master the process of derrick and substructure raising and lowering.

(3) Inthe way of human-machine interaction, the system provides training and testing of land rig installing process.

(4) The system uses real rig as prototype. All the levers, meters and gauges, switches are the same as the real equipment. The operation and display of brake lever, clutch and weight indicator is the same as the real equipment.

(5) 3D animation simulates the real environment. The animations can display downhole conditions, equipment motions and equipment working theories. Various worker and their relationship, standing position and operation rules are presented by animation characters. The graphics software provides scene displaying toggling and split-screen display. For example, rig monkey platform scene, drilling fluid flow path and various curves and real time data.

3.2 Training Project

-

Rig installing whole process training operation

-

Rig installing virtual assembly operation

-

Raising and lowering operation

1) Derrick raising operation

2) Substructure raising operation

3) Substructure lowering operation

4) Derrick lowering operation

Drilling operation

1) Normal trippinginoperation

2) Normal tripping out operation

3) Normal drilling and making up stand operation

Judging and treating of downhole accidents and troubles

1) Trippinginand slacking off

2) Tripping out and overpull

3) Judging and treating wall-sticking

4) Judging and treating sand settling

5) Judging and treating balling up

6) Normal drilling and drilling with bouncing bit

7) Judging and treating leaking accident

8) Fishing tap

9) Junk milling

4. Technical Parameters and Operational Environment

4.1 Technical Parameters

(1) Powersupply:220V/50Hz AC

(2) Power consumption: <6000W

4.2 Operational Environment

(1) Area: 10*8.5m

(2) Separate equipment power supply fromlightpower supply

(3) Working temperature: 0℃~30℃

(4) Relative humidity: <90%

5. Program Running Interfaces

Figure 1 Typical program running interfaces

Our strength

- Reliability

- Stable and reliable software and hardware

- Reality

- Highly realistic 3D scene display

- Service

- Timely and considerate after-sale service

F&Q

- Why is your simulator better than other simulators I’ve used in the past?

With the mission of “Assist training, reduce accidents and benefit the society”, Esimtech have been doing their best to design, develop and service every simulator. Esimtech simulator has its features as strictness, reliability, realisticness, lifelikeness. Problems and incident playback function enables trainees to experience troubles for any time which helps trainees to better master the skills of judging and handling of common troubles.

- Do you have any happy clients or testimonials about your simulator?

“Creating value for customers”, which is always emphasized in our company. With this original intention, Esimtech Company develops simulators with high quality, and provide timely and enthusiastic services. For all these years, the products and services provided by Esimtech are highly praised by our customers.

- Can you do custom work for my specific rig, company, or field?

Esimtech provides customization service, which is the biggest feature of the company. Esimtech has a strong production team skilled at programming and animation production. Both hardware and software can be customized to comply with the real situation.

- How would I get the simulators if I ordered?

The package will be shipped to the customer’s facility. If necessary, Esimtech provides onsite installation and training services.