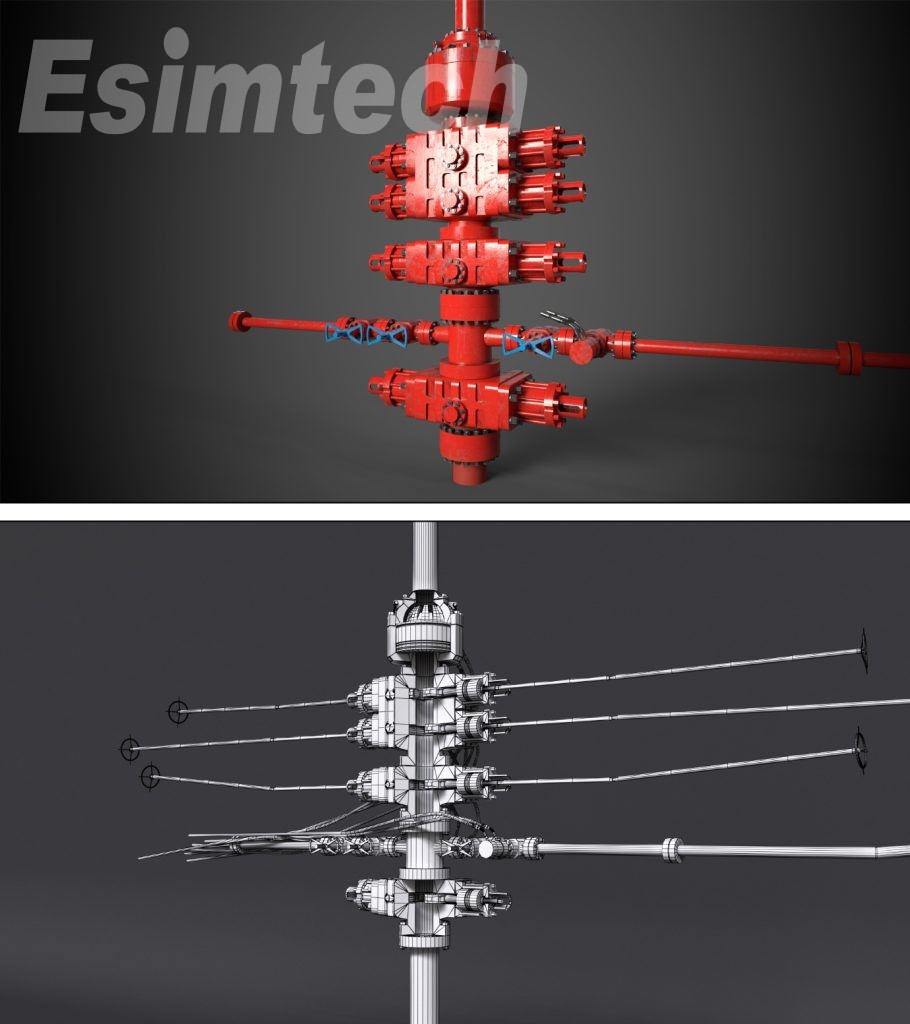

Animation of Drilling and Well Control Devices Assembly and Disassembly and Working Principle

The animation shows the inside structure, working principle, assembly and disassembly of drilling and well control devices, which makes students familiarize with the component and principle of drilling and well control devices, master the examining and commissioning of the main working system of the devices, and able to analyze and judge the working condition of the devices so as to clear trouble in time.

Drilling and well control devices assembly and disassembly and working principle animation includes the following:

F&Q

- What is a petroleum simulator?

A simulator is a device that simulates an environment for the purpose of training or research. A petroleum simulator is a set of devices that simulates the well site environment, the real operation devices, the operation method, parameter display way, etc. with which trainees can be access to a virtual well site environment, where they can get familiar with the relative devices, how to operate the devices, what phenomenon there will be if there is a problem, what’s happening underground, etc.

- Why is the simulator necessary to oil and gas industry?

Since the beginning of the 20th century, simulators have been used in different industries as tools to train and to facilitate the growth of the operators of the machinery. This type of training is, without a doubt, one of the most effective ways to mitigate labor risks, develop the skills needed, and increase productivity.

In oil and gas industry, accidents happen from time to time, such as blowout, H2S leakage, fire, explosion, machinery injuries, etc. Working in the oil and gas field is of high risk. According to statistics, almost 36% of these accidents were caused by mistakes in operation. Sufficient pre-post training is essential. A simulator makes this possible, which provides a virtual training environment, for new staff the get familiar with the working environment, site scene, and operation devices in advance. With the simulator, new staff can also experience the common incidents which may occur in real operations, and learn to judge and handle emergencies. So that in real work, most of the accidents can be judged or avoided in an early stage, and therefore reduces risks and increase production.

- What well control simulations does this well control simulator cover?

In well control operation, pressure control is very important. How the pressure is controlled? In the well control simulator, various scenes of kick can be simulated, both hard and soft shut-in procedures can be carried out. Meanwhile, various well-killing methods are provided, such as the driller’s method, engineer’s method, volumetric method, bullheaded, low choke method, standpipe pressure method, etc.

- What new petroleum simulations and features are you working on?

Esimtech has been committed in study and developing petroleum engineering simulation training systems for about 30 years, and has a series of independent intellectual property rights. Our simulators are widely used in many training companies with good feedback. To keep pace with the international standard and demand, Esimtech is now studying and developing an MPD simulator, where some achievement has been reached.