The Transformative Role of Extended Reach Drilling in Mature Oil and Gas Fields

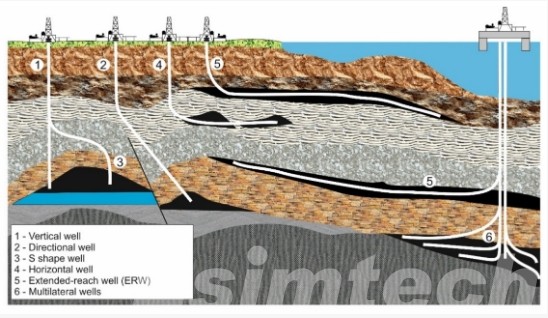

Extended Reach Drilling (ERD) is an advanced drilling technique used in the oil and gas industry to access reserves located far from the drilling platform. In mature oil and gas fields, where easy-to-reach resources have already been exploited, ERD drilling plays a crucial role in maximizing production and extending the life of these fields. This article explores the significance, challenges, and solutions of Extended Reach Drilling in mature oil and gas fields.

Understanding the Basics of Extended Reach Drilling

Here’s a chart outlining the basics of Extended Reach Drilling.

| Aspect | Description |

| Definition | Extended Reach Drilling (ERD) is a drilling technique used to access distant subsurface targets from a single drilling location. It involves drilling horizontally or at high angles over extended distances to reach reservoirs beyond the reach of conventional drilling methods. |

| Objective | The primary objective of ERD drilling is to access and exploit hydrocarbon reserves located far from the drilling platform. This technique allows operators to maximize resource recovery, extend the life of mature fields, and optimize production efficiency. |

| Key Components | Drill String: Consists of drill pipe, drill collars, and drill bit, used to penetrate the earth’s subsurface. Drilling Fluids: Circulate through the drill string to cool the drill bit, carry cuttings to the surface, and provide stability to the wellbore. Downhole Tools: Equipment installed in the drill string to perform specific functions, such as logging, steering, and drilling optimization. |

The Significance of Extended Reach Drilling in Mature Oil and Gas Fields

1. Maximizing Resource Recovery

Access to Untapped Reserves

Mature oil and gas fields often contain substantial reserves that are not easily accessible with traditional vertical drilling methods. Extended Reach Drilling enables operators to reach these distant deposits, which can be several kilometers away from the drilling site. This capability is essential for fully exploiting the remaining resources in mature fields, thus increasing overall recovery rates.

Enhanced Reservoir Contact

ERD techniques allow for greater contact with the reservoir by creating longer horizontal sections of the wellbore. This increased exposure to the hydrocarbon-bearing formation enhances the flow of oil and gas into the well, leading to higher production rates and more efficient extraction of resources.

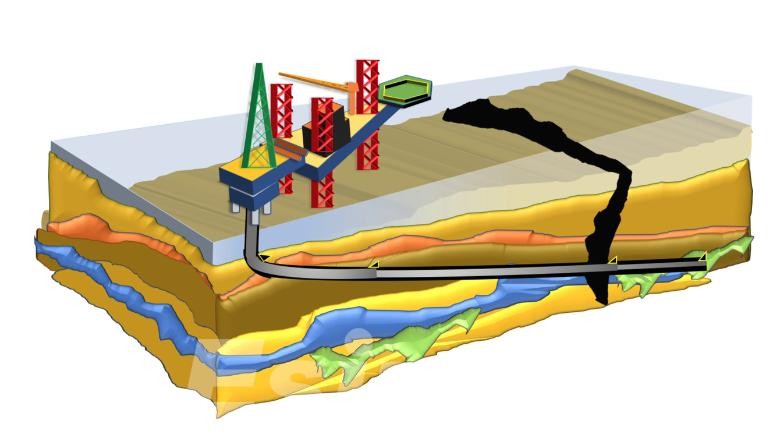

Optimized Use of Existing Infrastructure

By utilizing ERD drilling, operators can maximize the use of existing infrastructure, such as platforms and pipelines, without the need to build new facilities. This not only extends the life of mature fields but also optimizes the return on investment in existing assets.

2. Economic Benefits

Cost Efficiency

Extended Reach Drilling can significantly reduce the costs associated with developing oil and gas resources. By accessing multiple reservoirs from a single drilling location, operators can minimize the need for additional drilling platforms and surface facilities. This reduction in infrastructure costs, combined with the enhanced production rates from ERD wells, improves the overall economic viability of mature fields.

Increased Operational Efficiency

The ability to drill longer and more complex wells from a single location leads to increased operational efficiency. ERD drilling reduces the time and resources needed for drilling operations, resulting in lower operational expenses and higher profitability for operators.

Reduced Downtime

Extended Reach Drilling allows for continuous production without the interruptions that come with relocating drilling rigs. This continuous operation ensures a steady flow of oil and gas, contributing to consistent revenue generation and better resource management.

3. Environmental Benefits

Minimized Surface Footprint

ERD drilling significantly reduces the number of drilling sites needed to access a reservoir. Fewer platforms and wells mean less disturbance to the environment, leading to a smaller surface footprint. This is particularly important in environmentally sensitive areas where minimizing land use and habitat disruption is a priority.

Reduced Environmental Impact

By drilling from existing platforms and infrastructure, Extended Reach Drilling minimizes the need for new construction in pristine or sensitive environments. This reduction in new infrastructure development helps to protect ecosystems and reduce the overall environmental impact of oil and gas extraction activities.

Sustainable Resource Management

ERD drilling contributes to more sustainable resource management by maximizing the extraction of hydrocarbons from mature fields. By extending the life of these fields, ERD helps to ensure that resources are used efficiently, delaying the need to explore and develop new fields, which often come with higher environmental costs.

Key Challenges and Corresponding Solutions for Extended Reach Drilling in Mature Oil and Gas Fields

1. Wellbore Stability

- Challenge Description: Drilling through various geological formations, including depleted zones, can lead to wellbore instability and collapse.

- Solution: Use optimized mud programs to balance formation pressures, implement real-time wellbore monitoring systems, and deploy wellbore strengthening techniques like casing while drilling or expandable tubulars.

2. Torque and Drag

- Challenge Description: Increased well length results in higher torque and drag, causing difficulties in rotating the drill string and moving it in and out of the hole.

- Solution: Use torque-reduction tools such as downhole lubricators, friction-reducing coatings, and rotary steerable systems (RSS). Regularly backream and use proper hole-cleaning practices to minimize cuttings buildup.

3. Hole Cleaning

- Challenge Description: Efficient removal of drill cuttings, especially in long horizontal sections, is critical to avoid stuck pipe and other issues.

- Solution: Optimize drilling fluid properties to enhance cuttings transport, increase pump rates, and implement periodic wiper trips. Use real-time cuttings monitoring and advanced cuttings transport models.

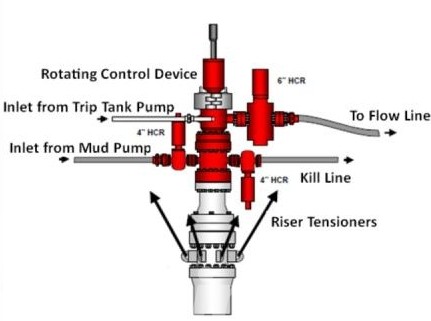

4. Pressure Management

- Challenge Description: Maintaining the correct pressure balance is crucial to avoid well control issues such as kicks and fluid losses.

- Solution: Use managed pressure drilling (MPD) techniques to control annular pressures precisely. Deploy real-time pressure monitoring and adjust mud weight and composition dynamically.

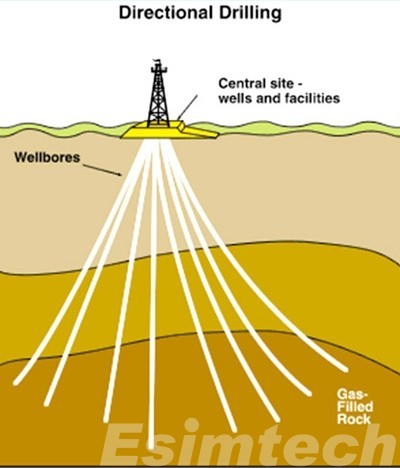

5. Directional Control

- Challenge Description: Ensuring the well follows the planned trajectory over long distances is challenging and requires precise control.

- Solution: Utilize advanced directional drilling tools such as RSS, and MWD/LWD technologies. Continuously monitor the wellbore trajectory and make real-time adjustments to the drilling parameters.

6. Fatigue and Mechanical Stress

- Challenge Description: The drill string and casing experience significant mechanical stress and fatigue over extended distances.

- Solution: Use high-strength, fatigue-resistant materials for drill strings and casings. Perform stress analysis and fatigue management, and conduct regular inspections and maintenance.

7. Logistical and Operational Complexity

- Challenge Description: Coordinating the logistics of equipment and materials for extended reach drilling operations is complex.

- Solution: Implement detailed planning and project management tools. Use simulations to optimize logistics and operational workflows, and ensure effective communication and coordination among teams.

8. Cost and Economic Viability

- Challenge Description: Extended Reach Drilling operations are typically more expensive due to the advanced technologies and techniques required.

- Solution: Conduct thorough economic assessments to ensure project viability. Optimize well design to maximize resource recovery and reduce costs through technology and process innovations.

9. Environmental and Safety Concerns

- Challenge Description: The complexity and scale of ERD operations increase the risk of environmental and safety incidents.

- Solution: Adhere to strict environmental and safety regulations. Implement robust safety management systems, use environmentally friendly drilling fluids, and conduct regular safety drills and training.

9. Integrated Solutions

Advanced Drilling Technologies

- Measurement-While-Drilling (MWD) and Logging-While-Drilling (LWD): Implement MWD and LWD tools for real-time data on wellbore conditions, enabling immediate adjustments.

- High-Strength Materials: Utilize high-strength, fatigue-resistant materials for drill strings and casings to withstand mechanical stress and fatigue over extended distances.

- Casing While Drilling (CWD): Use CWD to improve wellbore stability and reduce non-productive time by simultaneously drilling and casing the well.

- Expandable Tubulars: Deploy expandable tubulars to reinforce wellbore integrity and reduce the risk of wellbore collapse in unstable formations.

Real-Time Data Analytics and Monitoring

- Real-Time Monitoring Systems: Deploy real-time monitoring systems for wellbore stability, pressure management, and hole cleaning. This includes downhole sensors and surface data acquisition systems.

- Predictive Analytics: Use predictive analytics to foresee potential problems such as wellbore instability, stuck pipe, and pressure anomalies, allowing for preemptive measures.

Collaborative Technologies

- Digital Twins: Create digital twins of the drilling operations to simulate and optimize drilling performance, predict potential issues, and test solutions in a virtual environment.

- Integrated Software Platforms: Use integrated software platforms for real-time data sharing, decision-making, and project management across all teams and stakeholders.

Conclusion

Extended Reach Drilling is a transformative technology that offers significant advantages for maximizing production from mature oil and gas fields. Despite the technical challenges and risks associated with ERD drilling, advancements in drilling technology and techniques continue to enhance its feasibility. As the demand for energy resources grows, ERD drilling will play an increasingly important role in ensuring the sustainable and efficient development of mature oil and gas fields.