Effective Methods for Wellbore Stability Analysis

The wellbore stability is vital because it contributes to the safety, efficacy, and economic viability of the drilling efforts in the oil and gas sector. Wellbore instability is dangerous because it can result in the wellbore collapsing, becoming stuck, or losing fluid. All of these consequences are costly and time-consuming to rectify. Wellbore stability analysis enables the successful and safe implementation of drilling programs.

What is Wellbore Stability

Wellbore stability is defined as the capacity of the wellbore to endure the various forces acting on it while it is still active. These forces include the subsurface geological and physical conditions, the drilling parameters and the properties of the drilling fluid. Wellbore stability is an ongoing process, and it is essential for the drilling operator to maintain control of the well throughout the drilling, completion and production phases, to prevent complications that would damage the well and endanger the surrounding area.

The Risks of Wellbore Instability

This chart summarizes the main risks associated with wellbore instability, highlighting the potential consequences that can arise from each risk during drilling operations.

| Risk | Description | Potential Consequences |

| Wellbore Collapse | Occurs when the formation around the well fails to maintain its structure under pressure. | Blocked wellbore, expensive remedial work, potential well abandonment, and loss of drilling time. |

| Stuck Pipe | When the drill string becomes lodged in the well due to differential pressures or formation instability. | Extended downtime, costly repairs, potential damage to drilling equipment, and possible well failure. |

| Lost Circulation | The loss of drilling fluid into porous formations, fractures, or faults. | Increased operational costs, delays in drilling, need for additional materials and services, and potential formation damage. |

| Fluid Influx (Kick) | The uncontrolled flow of formation fluids into the wellbore due to imbalance in pressure. | Risk of blowouts, unsafe working conditions, and significant safety hazards to personnel and the environment. |

| Casing Failure | Weakening or collapse of casing in the wellbore, often caused by excessive pressure or inadequate design. | Well integrity failure, possible environmental damage, costly repairs, and the potential to lose the well permanently. |

| Formation Damage | Physical or chemical changes to the formation around the wellbore, reducing its ability to produce. | Lower production rates, damaged reservoir, and costly remediation work to restore wellbore functionality. |

| Wellbore Erosion | The wearing away of the wellbore walls due to excessive drilling speed, mud composition, or formation type. | Increased friction, damage to equipment, and a weakened wellbore structure that can lead to collapse or stuck pipe. |

| Kickoff Point Instability | Instability occurring at the kickoff point when drilling deviates from vertical to horizontal. | Wellbore instability in horizontal sections, increased risk of stuck pipe, and difficulty maintaining wellbore trajectory. |

| Borehole Deviation | Misalignment or deflection of the wellbore path due to unstable formations or poor drilling parameters. | Difficulty in reaching target zones, inaccurate well placement, and potential increases in operational costs. |

| Formation Swelling | Swelling of reactive formations (like shale) when they come into contact with drilling fluids. | Wellbore narrowing or blockage, delayed drilling progress, and the need for specialized drilling fluid management. |

The Importance of Wellbore Stability

Ensuring Safe and Effective Drilling Operations

To ensure safe and effective drilling operations, preventing wellbore instability is of utmost priority. Careful planning and active control of the drilling process are the primary means of achieving this goal. Understanding formation conditions, pore pressure, fracture gradients, and in-situ stress is critical to determine the wellbore stability profile during the drilling operation.

Impact on Operational Efficiency and Costs

Impact of wellbore instability on efficiency and cost of operations is notable. Continuously and cost-efficiently repaired and remediated operations can sequenced, flowing from one stage to the other without the need to interrupt drilling to resolve wellbore instability. Conversely, operational costs are escalated by improperly sequenced, prolonged, and disrupted drilling, damaged equipment, and the missing of predestined deadlines.

Reduced operational predictability, and resulting cost, are driven by the need to resolve operational concerns of pipe sticking, wellbore instability, and lost circulation. To better predict the operational costs and resulting cash flow, the operational timelines should identify gaps and missing sequences.

Enhancing Safety

The safety of all drilling operations is of utmost importance. Wellbore stability is fundamental to the safety of the working environment. Unrestrained wellbore sleeping or wellbore fluid influx situations can lead to well uncontrolled blowout cascading to unsafe environments for both people and the ecosystem.

Drill operators and engineers improve wellbore stability to provide better working safety and wellbore fluid pressure stability. This provides workers with greater stability and less risk of uncontrolled wellbore situations through their working shift. Risk levels can be ensured by engineers and implemented safety controls. This safety shift ensures the environment and the people end of the well drilling operation are safe.

Ensuring Long-Term Well Integrity and Production

Even after the drilling phase is complete, wellbore stability is integral to the longevity, success, and overall integrity of the well throughout its complete life cycle. If a wellbore is stable, the casing and completions can be installed properly, allowing the well to produce efficiently and minimizing the chances of future failures.

In addition to wellbore stability, managing well integrity is also essential. The safe extraction of hydrocarbons, and the elimination of the risk of well leaks or failures during production, rely on the wellbore remaining stable throughout the life of the well.

Common Methods Used in Wellbore Stability Analysis

1. Mechanical Earth Modeling (MEM)

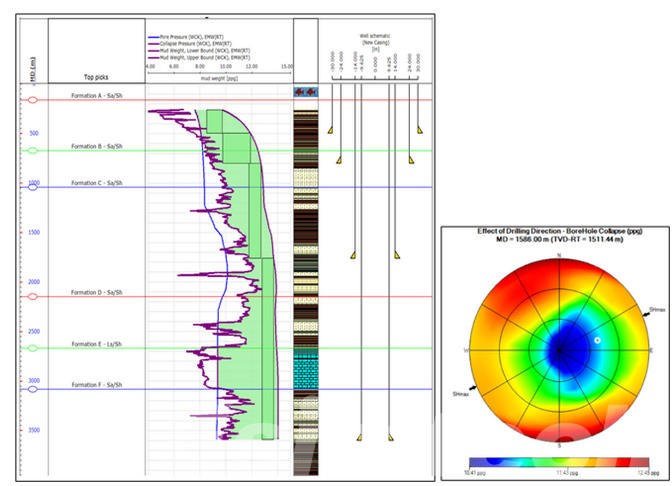

Mechanical Earth Modeling is a robust technique that has the capacity to approximate the mechanical response of a wellbore and the surrounding rock formations. It is because this technique assimilates data from geology, geophysics, petrophysics, and rock mechanics to devise a model for the formation’s response to a variety of drilling-related stresses.

Mechanical Earth Modeling simulates the rock formations’ strength and the formations’ stress regime (vertical and horizontal), and pore pressure. The estimation provides the basis to assess formation response for varying formation mud weight, pore pressure, and in-situ stress. Mechanical Earth Modeling aids in pinpointing wellbore critical areas that are most likely to become unstable, weak, or fractured, and helps devise strategies to counter potential failure.

This technique is unique in that it has the ability to outline wellbore trajectories and identify areas where drilling would pose the greatest risk. Mechanical Earth Modeling is applicable to vertical and horizontal wells, providing a complete picture of the wellbore stability along the entire length.

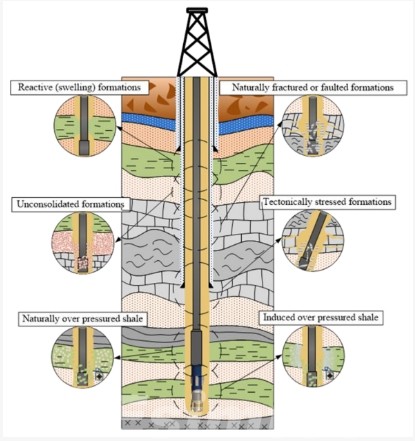

2. Stress and Strain Analysis

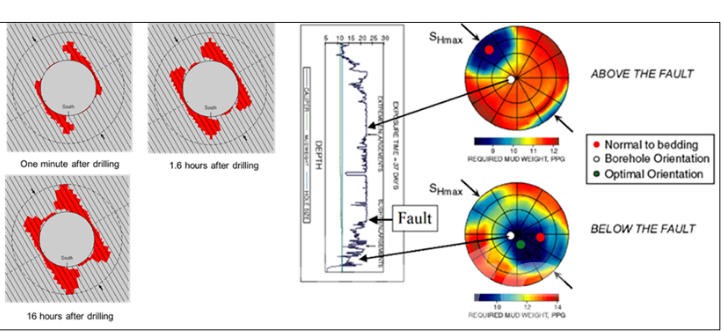

Stress and strain analysis involves understanding the methods for determining the stability of the wellbore by evaluating the likelihood of collapse from the forces acting on a wellbore. This involves determining the stresses and strains in the adjacent rocks, and ultimately, this will assist in predicting the reaction of a wellbore to different conditions.

In the case of the evaluation of the collapse or fracture, it becomes imperative to analyze the stresses. Of the different primary stresses, tangential stress- which refers to the stress on the walls of the wellbore, and radial stress- the stress coming from the surrounding formations, and axial stress- relating to vertical forces- will determine the equatorial balance of the wellbore. A combination of the stress and strain will determine the pressure points and estimate the conditions mud weight and drilling processes will retain optimal balance.

In formations that contain more complicated stress regimes, the wellbore will likely remain stable. Evaluating the different stress patterns that will minimize the risk of collapse will allow for better design and planning. This includes formations that contain multiple fault lines and formations that are highly pressurized.

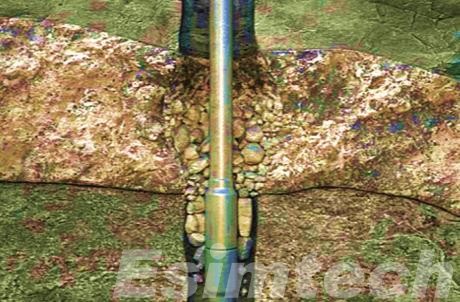

3. Mud Weight Optimization

Adjusting the weight of the drilling fluid (mud) is a technique aimed at achieving the ‘balance pressure ratio’ so that the formation pressure is stable at a wellbore. The hydraulic pressure provided by the drilling mud is able to control the pressure of the wellbore, prevent it from collapsing, transport the cuttings from the well, and control the formation pressure during drilling. These functions of the drilling fluid can collapse the wellbore if the mud weight is poorly adjusted, and hence, it becomes a challenge to stabilize the wellbore.

A wellbore will lead to collapse if the mud weight is too low and it will fracture the formation and lose circulation of the mud if the weight is too high. The goal of mud weight optimization is to ensure the required wellbore hydrostatic pressure while avoiding fractures of the rock.

This methodology involves determining the optimal mud weight for different sections of the wellbore while considering the formation pore pressure, fracture gradient, and other geological considerations. Since mud weight can be altered during drilling, engineers make adjustments based on real-time information from LWD (logging while drilling) and other monitoring technologies. In wellbore optimization, the efforts mud weight adds on wellbore instability, lost circulation risk, and formation damage are of utmost importance.

4. Finite Element Analysis (FEA)

Finite Element Analysis is a computational technique used to simulate the behavior of the wellbore and surrounding formation under various stress conditions. To perform wellbore FEA, the wellbore and surrounding rocks are discretized into small elements (or “nodes”) to control the computation of internal stress and sequence of formation actualization. This also facilitates the computation of inter-element conditions. Logical control structures allow the integration of dummy elements into the computation sequence as stressed ones are progressively actualized.

FEA aids the engineer in analyzing the entire system of the wellbore, including casing, cement, mud, and the formation around it. Because the model analyzes system response on various inputs of stress and pressure over time, it can be used to predict formation behavior during wellbore drilling. FEA is also valuable in simulating wellbore stability under multiple stress conditions. Simple models are likely to yield errors in formations that are complex and heterogeneous, and this is where FEA excels.

FEA assists in uncovering weak points and failure zones by evaluating the distribution of stress and strain in the wellbore. It can be employed to improve wellbore design and drilling parameters to ensure wellbore stability in a variety of conditions.

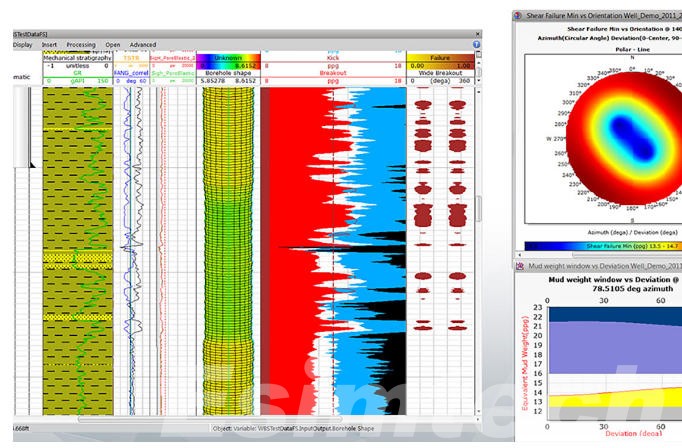

5. Real-Time Monitoring and Logging

Real-time monitoring and logging are the most important techniques for managing and mitigating wellbore instabilities. Logging While Drilling (LWD) and Measurement While Drilling (MWD) technologies permit engineers to collect drilling-time data regarding the condition of a wellbore, including aspects such as mud pressure, torque, rate of penetration (ROP), and formation characteristics.

The continual observation of these variables enables the recognition of initial signs of wellbore instability. These signs can include changes in mud pressure, higher torque, and unexpected ROP fluctuations. These changes can be corrected by altering drilling parameters, changing mud properties, or modifying the wellbore design to preserve stabilization and avoid failure.

Real-time information can be used to improve wellbore stability prediction models, which allows engineers to refine their drilling operation simulations. This technique ensures the most current, responsive approach to stability, which addresses the management of emergent risks.

6. Geomechanical Modeling

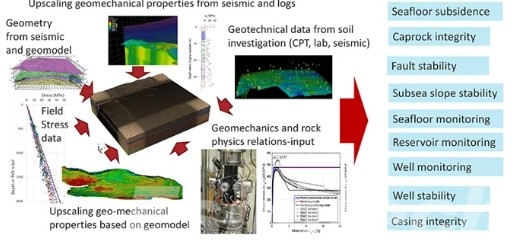

Geomechanical modeling refers to the simulation of the mechanical behavior of stressed rock masses using computer technology. This technique attempts to integrate rock mechanics with the geology of a region to ascertain the formation’s response to drilling stresses, temperature, and pressure variations.

Assessing the likelihood of wellbore instability, i.e., wellbore collapse, fault activation, and fluid influx, is possible with the use of geomechanical models. Engineering formation response simulations to varying drilling parameters allows the isolation of areas with the highest likelihood of instability and the implementation of mitigation strategies.

The importance of geomechanical modeling increases in geologically complex areas, i.e., deepwater drilling sites, layered shales, and high temperature and pressure reservoirs, where the need to optimize drilling operations is pressing. This advanced technique reduces the likelihood of operational instability by providing a holistic understanding of the formation.

Challenges and Solutions in Wellbore Stability Analysis

This chart provides common challenges encountered in wellbore stability analysis and the solutions available to mitigate those risks and enhance the safety and efficiency of drilling operations.

| Challenge | Description | Solutions |

| Geological Uncertainty | Inadequate or incomplete geological data can lead to inaccurate stability predictions. | Use of advanced seismic surveys, well logging, and geological modeling to gather more accurate formation data. |

| Complex Stress Regimes | Wellbore instability can occur in formations with varying stress orientations and magnitudes. | Geomechanical modeling and Mechanical Earth Modeling (MEM) to simulate and account for complex stress patterns. |

| Formation Heterogeneity | Rock formations can vary widely in strength and behavior, complicating stability predictions. | Finite Element Analysis (FEA) and advanced rock mechanics models to simulate heterogeneous formations. |

| Real-Time Data Integration | Difficulty in integrating and interpreting large amounts of real-time drilling data. | Use of real-time monitoring tools like LWD and MWD with automated data analysis platforms. |

| Mud Weight Optimization | Balancing the correct mud weight to prevent both wellbore collapse and formation fracturing. | Continuous mud monitoring, simulation models, and adaptive real-time adjustments to mud properties and weight. |

| Dynamic Formation Properties | Formation properties, such as pore pressure and strength, can change during drilling. | Real-time formation evaluation using advanced sensors (LWD/MWD) and integration with geomechanical models. |

| High Pressure and Temperature Conditions | Extreme conditions in deepwater or high-temperature wells can cause formation weakening. | Use of specialized mud systems, temperature-resistant materials, and advanced geomechanical simulations to account for extreme conditions. |

| Casing and Liner Integrity | Inadequate casing or liner design can lead to wellbore collapse or leakage. | Oil and gas simulation tools to design optimal casing programs and ensure proper liner installation. |

| Loss of Circulation and Fluid Influx | Lost circulation and uncontrolled fluid influx are common risks in unstable formations. | Flow modeling, fracture simulations, and controlled mud weight optimization to prevent and manage fluid loss and influx. |

| Prediction of Stuck Pipe | Stuck pipe incidents occur when differential pressure or unstable formations cause blockage. | Stress and strain analysis to identify high-risk zones, coupled with real-time adjustments to drilling parameters. |

| Lack of Real-Time Wellbore Monitoring | Inability to detect early signs of instability or failure during drilling operations. | Deployment of real-time data collection systems such as LWD/MWD, coupled with integrated analysis software for immediate decision-making. |

Summary

To ensure safe and effective drilling operations, wellbore stability analysis is essential. As the use of advanced engineering methods, real-time information and predictive modeling decrease wellbore instability risk, the success of drilling operations improves. Innovations in drilling methods will also contribute to the development of predictive analysis, refining wellbore integrity and improving drilling operations.