Floating Production in Offshore Drilling

In recent years, offshore drilling has become more dependent on advanced technologies for production. These include the use of floating production systems, which have become crucial for the safe, cost-effective, and flexible extraction of hydrocarbons in deep and ultra-deep water offshore drilling.

What is Floating Production

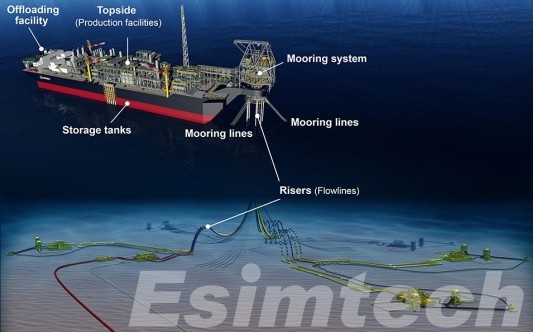

Floating production refers to systems or structures that are connected to buoys and can float on water. Floating buoys can have either a fixed mooring to the ocean floor or are connected to a surface vessel that is dynamically positioned on the water surface. These systems are almost always a requirement in offshore drilling, because drilling below the surface becomes economically and mechanically challenging.

What Drives Floating Production in Offshore Drilling

- Access to Deepwater and Ultra-Deepwater Reserves

Floating production systems have the capability to operate in deep water or ultra-deep water drilling. These systems expand the offshore production boundaries, which is a huge economic advantage. Traditional, fixed platforms, are not economically feasible in extreme ocean depths. Floating systems are essential to the future of offshore oil and gas drilling.

- Flexibility and Redeployment Capabilities

Floating production systems have no parallel flexibility. Units like FPSOs can be moved to new fields after depleting ones, lowering the need for permanent structures, and allowing rapid response to shifts in production need. This flexibility makes the technique useful for both very new and aging fields.

- Integration of Production, Storage, and Offloading

The ability to integrate production, storage, and offloading along a single floating platform drives up operational efficiency. FPSOs, for instance, process crude oil, separate gas and water, then store the separated hydrocarbons for offloading to tankers. This decreased dependency on pipeline networks allows operators to control production in remote areas or regions lacking critical infrastructure.

- Economic and Operational Considerations

In certain cases, floating production systems can lead to a reduction in costs. While the initial investment on floating production systems is high, they cut down on the level of seabed construction and long distance underwater pipelines associated with fixed platforms. Moreover, the time taken to deploy floating production units is shorter than the time taken to build permanent facilities. This improvement in production time amplifies the project’s economics.

- Technological Advancements and Safety

Resorting to innovations in technology aiding the implementation of `floating production. Sophisticated mooring systems, dynamic positioning, remote monitoring, acquired technology, and automation, improve the operational safety, and reliability of the systems. The advancements in technology permits the floating units to survive and operate under severe climate conditions while ensuring there is production and the risk of an accident is decreased.

- Environmental and Regulatory Factors

Environmental factors, and the legal aspects of offshore floating production, also impose restraints. Floating systems often track and minimize the disturbance to the seabed compared to fixed installations, which is an advantage in more delicate marine regions. The ability to confine the floating systems to a designated area while still reducing the negative impact on the environment and abiding by international offshore regulations certainly promotes the utilization of floating platforms in offshore developments.

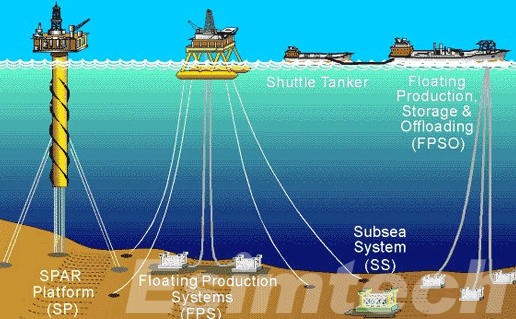

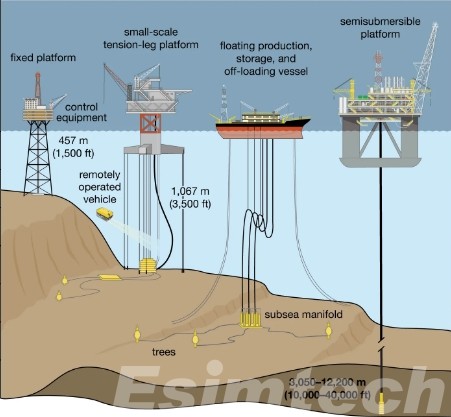

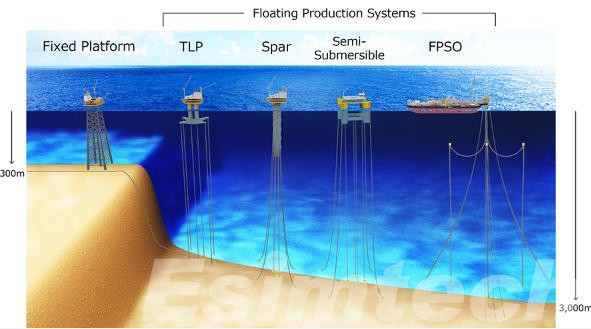

Types of Floating Production Systems in Offshore Drilling

To select the right solution for every offshore drilling operation, it is important to understand the system of various types of floating production systems.

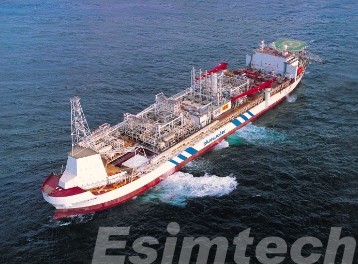

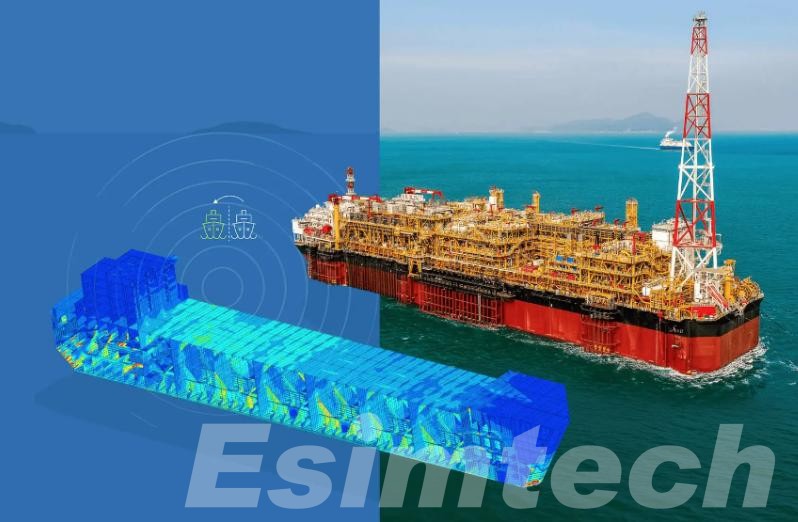

1. Floating Production, Storage, and Offloading (FPSO) Units

Floating Production Storage and Offloading Units are widely employed in offshore oil and gas operations as flexible floating production systems. They combine production facilities to store crude oil, process it, and then offload it to tankers. Apart from self-sustaining operations, FPSOs can be relocated to any other field once another is depleted. They don’t need any pipelines, and this independence together with their ability to offload huge amounts of oil and gas makes FPSOs in demand in ultra and deep sea waters.

2. Tension Leg Platforms (TLPs)

TLPs are floating structures like FPSOs, but unlike them, they are anchored to the seabed with tensioned cables. They are stable vertically while still allowing some movement for waves and currents. They are optimal deepwater platforms since other styles are rigid and unworkable in such depths. They also ensure structural safety while reducing stress exerted by the environment on the floating platform, which is the main purpose of a TLP.

3. Spar Platforms

Spar Platforms are round floating structures that extend deep into the water to gain stability through buoyancy and ballast. Production facilities are mounted on the hull and the topside stays above the water. Spars are typically used in ultra-deepwater projects because they are low cost and able to withstand harsh weather conditions. This design enables production to take place in regions with very stong current and high turbulence.

4. Semi-Submersible Production Platforms

Semi submersible production platforms are purposefully designed to float, and thus, are dipped partially in water. They are tethered either by anchors or through a dynamic positioning system. They are very stable and do not bob with wave motion, so they are optimal for severe conditions. Semi submersible platforms are able to perform drilling and production functions, thus, are ideal for long term deployments in deep water.

Challenges in Floating Production for Offshore Drilling

| Challenge | Description | Impact on Operations |

| Extreme Environmental Conditions | Harsh winds, waves, currents, and storms in deepwater areas | Can cause platform instability, equipment stress, and operational delays |

| Mooring and Positioning Complexity | Maintaining stability using anchors or dynamic positioning systems | Requires advanced technology; failure may disrupt production or cause safety hazards |

| Structural Integrity and Material Demands | Floating platforms face continuous stress and corrosion | Necessitates high-quality materials and regular maintenance; increases operational costs |

| Safety and Risk Management | Risk of blowouts, fires, or spills in offshore operations | Demands rigorous safety protocols and emergency response measures |

| High Capital and Operational Costs | Advanced systems, specialized vessels, and skilled personnel are required | Increases financial risk and project planning complexity |

| Logistical and Maintenance Challenges | Offshore location makes equipment repair, personnel access, and supply management difficult | Can lead to downtime, delays, and higher maintenance expenses |

| Environmental and Regulatory Compliance | Strict regulations for marine safety and environmental protection | Requires investment in eco-friendly technologies and continuous monitoring |

| Integration of Production Systems | Combining oil, gas, water separation, and storage on a single unit | Complex design and operational coordination needed; failure affects overall production |

How Simulation Technologies are Used for Optimizing Floating Production in Offshore Drilling

| Simulation Technology | Application in Floating Production | Benefits |

| Digital Twin Modeling | Creates a virtual replica of the floating platform, including production and structural systems | Enables predictive maintenance, scenario testing, and performance optimization |

| Hydrodynamic and Mooring Simulations | Models the effects of waves, currents, and winds on platform stability and mooring systems | Ensures safe design, reduces risk of structural failure, and optimizes positioning |

| Process Simulation | Simulates oil, gas, and water separation processes and overall production workflows | Improves efficiency, identifies bottlenecks, and tests operational strategies without affecting real operations |

| Emergency and Safety Drills Simulation | Models potential accidents, blowouts, or fire scenarios | Enhances preparedness, informs safety protocols, and trains personnel effectively |

| Fatigue and Structural Load Simulation | Evaluates stress, fatigue, and material performance under dynamic offshore conditions | Extends platform lifespan, prevents structural failure, and informs maintenance schedules |

| Environmental Impact Simulation | Assesses effects of offshore operations on marine ecosystems | Supports regulatory compliance, minimizes ecological footprint, and guides environmentally responsible design |

| Dynamic Positioning and Control Simulations | Tests control algorithms for thrusters and positioning systems | Optimizes platform stability, reduces operational risk, and improves energy efficiency |

Future Trends in Floating Production for Offshore Drilling

With ongoing advancements in the oil and gas industry, there are several trends forecasting the future of floating production, driven by innovation on the technology front, environmental concerns, and economic drivers.

Green Energy Integration

Floating production systems in the future are likely to use and incorporate renewable energies such as wind, solar, and hybrid systems in production to lower carbon emissions and the use of fossil-powered generators, environmental sustainability is also becoming an issue on most offshore operations. These environmental and economic controls on offshore production also tend to greening offsets better than compliance.

Ultra-Deepwater and Harsh Environment Development

The advancement in structural design, new materials and modern mooring systems all contribute to adding new challenged locations like ultra-deepwater reservoirs and areas with rough weather patterns to the floating production map. Progress in offshore exploration and production is bolstered by new systems and structures, while modern hull configurations and dynamic positioning systems in specialized ships ensure safety and stability in demanding environments.

Modular and Cost-Efficient Designs

The reduction in time and cost confirmed with an increase in production also tend to modular designs. These designs enable more than just rapid construction as the floating production units tend to use available components more economically, customizable to a standard order, and more than just rapid construction. With the new structures in place, maintenance and upgrades on modules are now easier to as compared to the past when the entire production system would need to be halted whenever modules needed to be replaced or serviced.

Enhanced Safety and Risk Management

Alongside operational efficiency, safety features are equally essential in offshore operations. Predictive technology, advanced sensors, AI-driven analytic systems, and real-time monitoring systems are poised to become central features of safety operations in the future. These systems will be crucial in hazard identification and accident prevention. Integrated safety systems, through the rapid response to emergencies, will limit the loss of personnel, damage to the environment, and destruction of the platform.

Summary

Offshore drilling has been transformed through floating production systems. Their adaptive systems for the extraction of hydrocarbons has made them more versatile and efficient, which is showcased through floating production systems. more for the world. They are able to enhance safety, offshore energy safety, and storage which helps with deepwater operations. With the advancement of technology, floating production will be more and more important for meeting global energy demands and addressing operational and environmental challenges .