Fundamentals of Cased Hole Logging: Techniques, Tools, and Applications

Accurate well evaluation does not end once the casing is set in the oil and gas sector. Cased hole logging plays a crucial part in achieving well performance, reservoir response, and long-term integrity. By providing critical information after drilling and completion, it helps operators make informed decisions that optimize production, minimize risks, and extend asset life. This article will explore the fundamentals of cased hole logging, methods, instruments, and primary applications so that you can understand it easily.

What is Cased Hole Logging Oil and Gas?

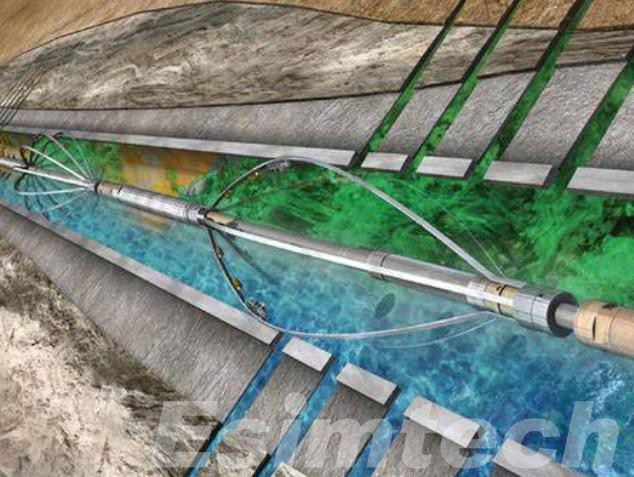

After a well has been drilled, cased, and cemented, cased hole logging within the oil and gas industry's scope is defined by a specific range of diagnostic measurements. In contrast to open hole logging, which is done before the installation of the casing, cased hole logging aims to deliver data throughout a well's production phase. This logging type is invaluable for the long-term management of reservoirs. It is especially important for well surveillance, active operational decisions, and real-time monitoring of changes to the well.

Cased hole logging seeks, within the constraints of tele-remote or attenuator equipment, to determine the condition of the wellbore and the wellbore surrounding formation without direct or physical contact with the rock. Operators can determine changes in fluid saturation, the quality of cement bonds, and the production contributions that different zones yield. This frees the well of economically recoverable hydrocarbons, ensures the safety of continued activity on the well, and extends the well's active life.

For oil and gas operators, the practice of cased hole logging is pivotal to consolidating well monitoring and attendant surveillance activities to actionable or operationally relevant insight and intelligence. This is critical to covering the seamless continuum of activities and performance that extends from drilling, through completion, to the reservoir's active and ongoing performance.

What are the Techniques often Used in Cased Hole Logging?

Cased hole logging utilizes specialized practices in understanding wellbore integrity, formation characteristics and production behavior, and wellbore logging techniques. Each method accomplishes distinct, yet collaborative, activities to enhance reservoir management and wellbore optimization.

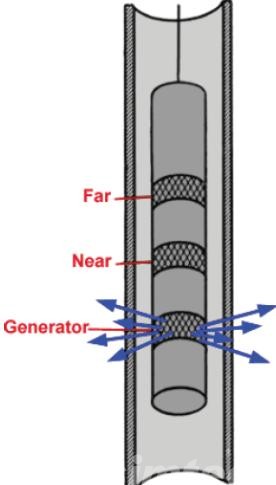

Pulsed Neutron Logging (PNL)

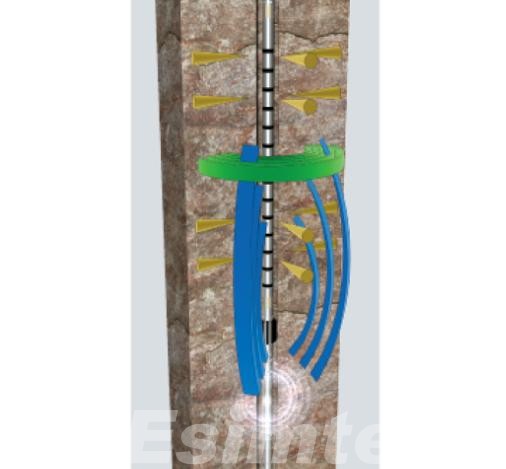

Being one of the most popular cased hole techniques, pulsed neutron logging involves neutron stimulation of the formation and the subsequent hydrogen-bearing fluid detection. By gauging water and hydrocarbon saturations behind the casing and gauging the evolution of gamma radiation, PNL assists in reservoir monitoring, water breakthrough zone detection, EOR performance evaluation, and reservoir performance change tracking.

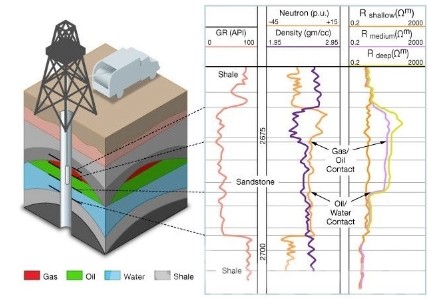

Gamma Ray Logging

Gamma ray logging, a technique that measures the natural gamma radiation of formation rocks and cased wellbore, also assists in lithologic identifiation and correlation with previously recorded open hole logs. This technique helps confirm the continuity of a mineral composition and formation in addition to reservoir characterization. For cased wells, gamma ray logging is an efficient method to confirm the continuity of petrophysical and geological data.

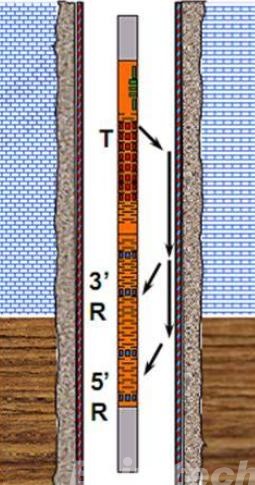

Cement Bond Logging (CBL/VDL)

CBL’s and VDL’s purpose is to determine the condition of the cement sheath that encases the casing. Defective bonding zones, micro-acrilli, or channels those integrated well might be cemented. Acoustic or sonic instruments that send a signal to cover casing cement determines well integrity lost. CBL confirms the zonal isolation to inhibit fluid from migrating behind the casing.

Acoustic and Sonic Logging

The casing’s and surrounding formations’ mechanical properties can be highlighted using acoustic and sonic tools. Other structural issues like cement bond, casing deformation can be flagged. Some other gauge instruments can assist formation evaluation in sonic logging.

Operators can make the best possible decisions considering the well’s entire life and the most valuable understanding close integrated due to these methods.

What are the Tools Used in Cased Hole Logging?

Cased hole logging is performed using different specialized instruments which are designed to function in completed wells. These kinds of tools are meant to assess the conditions of the wellbore, monitor the performance of the reservoir, and provide safe and efficient production during the entire life of the well.

- Nuclear Tools: Tools of this type, particularly the pulsed neutron and gamma ray instruments, are used frequently in cased hole logging. These instruments assess the formation characteristics that include fluid saturation, porosity, and lithology through the casing. They are used in reservoir fluid tracking and assessing the effectiveness of enhanced oil recovery (EOR) strategies and techniques over time.

- Acoustic Tools: These include the cement bond log (CBL) and sonic tools which assess the concrete and casing integrity. They accomplish this by transmitting sound waves through the casing and the cement which then reveals poorly bonded areas, micro annuli, or voids that could threaten the well integrity. These tools are used to confirm zonal isolation and the prevention of fluid migration behind the casing.

- Production Logging Tools (PLT): Production logging tools help understand fluid dynamics (flow, temperature, and pressure) for a cased well. Using flow automation and other instruments in PLT helps operators understand zonal contributions, detect gas or water production, and refine completion techniques, thus aiding interventions and re-perforations. Good knowledge on these factors helps plan for hydrocarbon recovery.

- Mechanical and Imaging Tools: Mechanical tools, such as calipers, detect casing wear, strip, and deformation, or loss, while imaging tools a provide wellbore and casing condition. These tools are very vital in mature fields, especially when casing integrity is needed.

Technological advancement has greatly enhanced these tools. Features like real time data down hole under valuable conditions have improved data garnered. All these tools serve the logging and operators in a well’s active and operational life.

What are the Applications of Cased Hole Logging?

Cased hole logging is crucial to the optimization of a well’s performance during its entire life cycle and its safety and reservoir management. It is crucial to the day to day operations and strategies of the well. This is why it is an integral part of modern well management.

Well Integrity Evaluation

Cased hole logging is useful in the measurement of well integrity. Tools like a cement bond log (CBL) and acoustic measurement devices can determine structural weaknesses, erosions of the cement and casing, structural leaks and channeling cement. Environmental protection can be achieved through the log monitoring of well operations. Providing operational safety and waste reduction is, sustainable also.

Reservoir Monitoring

Cased hole logging is integral in appreciating activities within a reservoir over time. Pulsed Neutron logs and Production Logging Tools (PLT) determine changes in the saturation of fluids in a reservoir, water encroachment and gas breakthroughs. With such information, operators can make better decisions concerning Enhanced Oil Recovery (EOR) projects, well stimulation and reservoir management.

Production Optimization

Production optimization is aided by cased hole logging using flow profiles, zonal contributions, and fluid composition fluid composition. Operators can determine and manage planned and unplanned recovery by identifying and detailing re-perforation and completion adjustment plans for effective recovery per zone.

Field Development and Planning

Cased hole logging data underpins and facilitates informed thinking for workovers, re-completion, well abandonment, and future operational strategy planning while ensuring development planning operational risk is streamlined.

Emerging Applications

Venture-based appendices on cased hole logging for untraditional gas and oil applications, such as tracking geothermal wells and monitoring CCS, broaden its market appeal beyond oil and gas.

Conclusively, cased hole logging is useful to operators for optimizing wells as it balances production and well integrity and then infuses strategic reservoir management through the well's life.

Conclusion

In the oil and gas industry, cased hole logging serves as one of the major facets of the industry, supplying pivotal information on the behaviors of the wellbore as well as the reservoirs, including the prevailing conditions during production performance. Using sophisticated methods and tools, operators track the movement of the cement and fluids, and then analyze the cement and fluids to enhance the recovery of the hydrocarbon. Such activities range from checking the hydrostatic seal to monitoring the reservoirs and optimizing the production, making it invaluable or necessary for basic activities, as well as emerging projects, such as carbon storage.

With the advent of technology, cased hole logging has also improved in the quality and accuracy of the data, the speed of the analysis, and the ability to assist in educated conjectures, which spans the entirety of the well’s life.