How Advanced Technologies in Well Logging are Revolutionizing the Oil and Gas Industry

Well logging, the practice of recording and analyzing geological formations encountered during drilling, is undergoing a renaissance with the advent of advanced technologies. These innovations are revolutionizing the oil and gas industry by providing deeper insights into reservoir characteristics, optimizing drilling operations, and enhancing environmental stewardship. This article explores the latest advancements in well logging technologies and their impact on the Oil and Gas industry.

Evolution of Well Logging Technologies

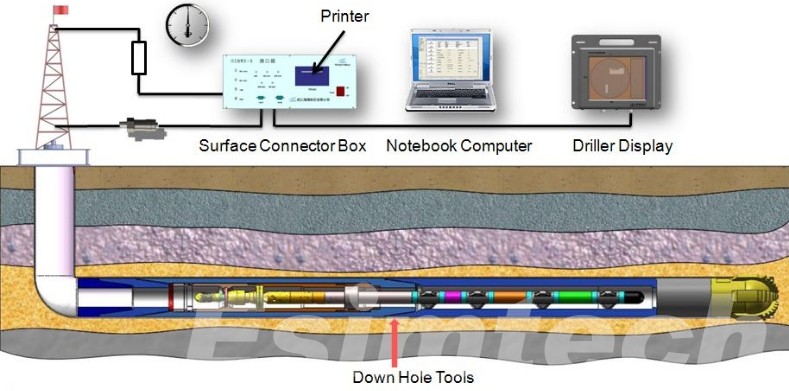

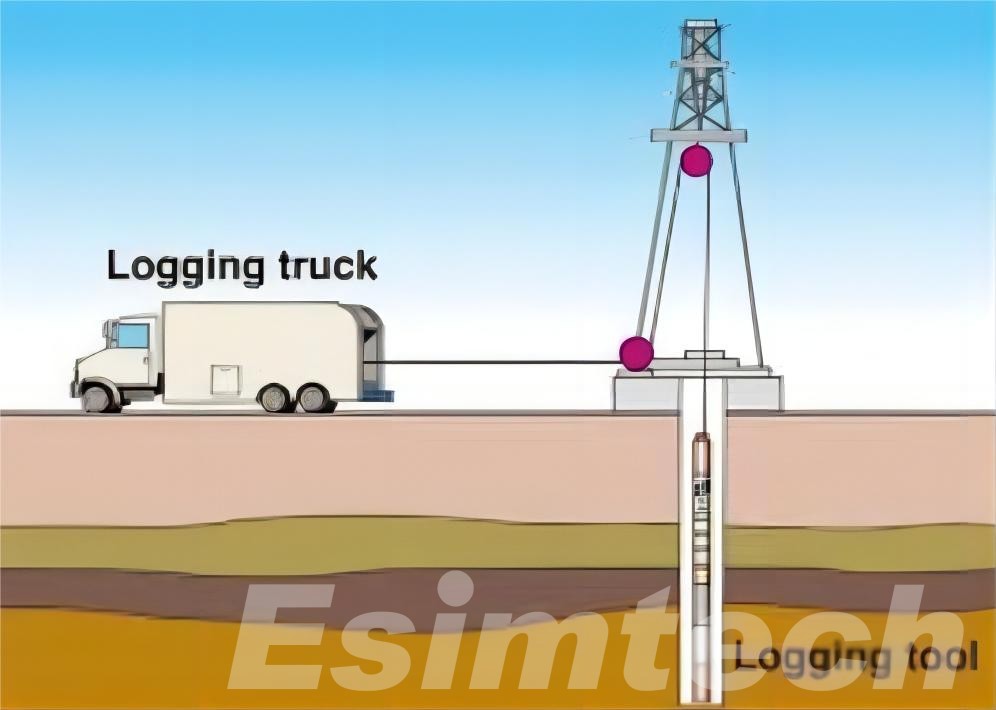

Traditional well logging methods, such as wireline logging, have long been the backbone of subsurface characterization. These methods involve lowering instruments down the wellbore to measure various properties, including gamma ray emissions, resistivity, and acoustic signals. While effective, these techniques often provided limited resolution and real-time capabilities.

Advanced Tools of Well Logging

1. Measurement While Drilling (MWD) and Logging While Drilling (LWD)

MWD and LWD drilling technologies enable real-time data acquisition while drilling. Measurement While Drilling and Logging While Drilling systems offer significant advantages in terms of efficiency, cost savings, and improved decision-making during drilling operations.

- Azimuthal Resistivity Tools: These tools measure the resistivity of formations in multiple directions around the wellbore, providing detailed information about formation anisotropy, fracture orientation, and reservoir boundaries.

- Magnetic Resonance Imaging (MRI) Tools: MRI logging tools use nuclear magnetic resonance (NMR) technology to directly measure fluid properties, such as pore size distribution, fluid mobility, and hydrocarbon saturation, offering insights into reservoir connectivity and producibility.

- Formation Pressure Tools: Formation pressure logging tools measure pore pressure and fracture gradients in real-time, helping to optimize wellbore stability, drilling fluid selection, and casing design.

2. High-Resolution Imaging Tools

- Borehole Imaging Tools: Borehole imaging tools use ultrasonic, acoustic, or optical sensors to capture high-resolution images of the wellbore wall, revealing geological features, formation textures, and drilling-induced damage.

- Microseismic Logging Tools: Microseismic logging tools detect and locate microseismic events induced by hydraulic fracturing or reservoir stimulation, providing insights into fracture propagation, reservoir connectivity, and geomechanical properties.

3. Advanced Petrophysical Tools

- Spectral Gamma Ray Tools: Spectral gamma ray logging tools analyze gamma ray spectra to identify and quantify specific elements and minerals in the formation, enabling lithology identification, mineralogy analysis, and reservoir compartmentalization.

- Dielectric Dispersion Tools: Dielectric dispersion logging tools measure the dielectric properties of formations over a range of frequencies, offering insights into lithology, porosity, and fluid type, especially in unconventional reservoirs.

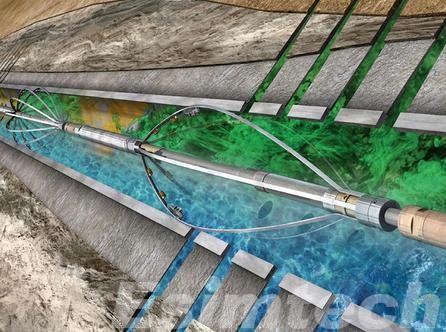

4. Wireless and Autonomous Logging Tools

Wireless and autonomous logging tools eliminate the need for cables or wires, enabling untethered operation in challenging environments such as extended-reach wells or deepwater drilling. These tools use battery-powered sensors and communication systems to transmit data to the surface in real-time, offering greater flexibility and efficiency in data acquisition.

Integration of Digital Technologies With Well Logging

1. Big Data Analytics and Machine Learning

The integration of big data analytics and machine learning algorithms with well logging data has revolutionized reservoir interpretation and decision-making. These technologies analyze vast amounts of data to identify patterns, correlations, and predictive models for reservoir properties, production behavior, and drilling performance, leading to more accurate predictions and optimized operations.

2. Cloud-Based Data Management

Cloud-based platforms facilitate the storage, management, and sharing of well logging data across geographically dispersed teams. These platforms offer scalability, security, and real-time access to data, enabling collaboration, data integration, and rapid decision-making across the organization.

Environmental Monitoring and Sustainability Technologies in Well Logging

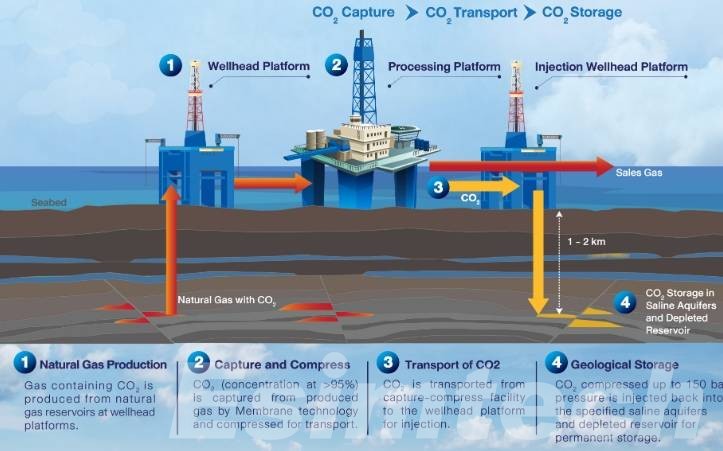

1. Carbon Capture and Storage (CCS) Logging

Advanced well logging technologies are being applied to monitor carbon capture and storage (CCS) projects aimed at mitigating greenhouse gas emissions. Specialized logging tools and methodologies assess CO2 injection and storage, evaluate reservoir integrity, and ensure long-term containment and security, supporting the transition to a low-carbon economy.

- Tracer Injection and Monitoring: Tracer injection techniques involve injecting chemical tracers into subsurface formations to track the movement and storage of injected CO2 in CCS projects. Monitoring technologies, such as downhole sensors and seismic monitoring, track the migration of CO2 plumes, assess reservoir integrity, and ensure long-term containment and security.

- Microseismic Monitoring: Microseismic monitoring techniques detect and locate microseismic events induced by CO2 injection, providing insights into reservoir behavior, fracture propagation, and potential leakage pathways in CCS reservoirs.

2. Groundwater Sampling Tools

- Downhole Sampling Tools: Specialized logging tools equipped with sampling capabilities can collect formation fluids and groundwater samples from downhole reservoirs. These samples are analyzed for chemical composition, contaminants, and hydrocarbon content to assess groundwater quality and potential environmental impacts.

- Packer Testing Tools: Packer testing tools isolate specific intervals of the wellbore to allow for controlled sampling and testing of formation fluids, providing insights into reservoir fluid properties, hydrocarbon composition, and fluid migration pathways.

3. Environmental Logging and Monitoring

Environmental logging tools are used to assess the impact of drilling and production activities on the surrounding environment, including groundwater quality, soil contamination, and emissions monitoring. These tools help operators comply with environmental regulations, minimize environmental risks, and demonstrate environmental stewardship.

How Innovative Simulation Technology Used in Well Logging

1. Reservoir Modeling and Simulation

Simulation software allows geoscientists and reservoir engineers to create detailed models of subsurface reservoirs based on geological data, well logs, and seismic surveys. These reservoir models simulate the complex interactions between rock formations, fluids, and production mechanisms, enabling predictions of reservoir behavior, fluid flow patterns, and production performance. Reservoir simulation helps optimize well placement, reservoir development strategies, and production enhancement techniques.

2. Wellbore Stability and Drilling Simulation

Simulation tools are used to model wellbore stability and drilling operations, predicting the behavior of the wellbore under various drilling conditions, such as formation properties, drilling fluid properties, and well trajectory. With drilling process simulation, engineers can identify potential challenges such as borehole instability, stuck pipe, or lost circulation, and develop mitigation strategies to minimize risks and improve drilling efficiency.

2. Well Logging Tool Design and Optimization

Simulation technology is employed in the design and optimization of well logging tools and sensors. Computational fluid dynamics (CFD) simulations can model fluid flow around logging tools, predict tool performance, and optimize sensor placement for accurate data acquisition. Finite element analysis (FEA) simulations help assess tool durability, structural integrity, and mechanical behavior under downhole conditions, ensuring reliability and performance in challenging environments.

3. Data Interpretation and Inversion

Simulation-based inversion techniques are used to interpret well logging data and extract subsurface properties such as lithology, porosity, permeability, and fluid saturation. These techniques simulate logging responses using forward models based on known physical properties and compare them with measured data to estimate reservoir parameters. Simulation-driven inversion enhances the accuracy and reliability of petrophysical interpretations, aiding in reservoir characterization and production optimization.

4. Real-Time Drilling and Logging Optimization

Real-time drilling and logging optimization software simulate drilling and logging operations in real-time, providing continuous updates on formation properties, wellbore conditions, and drilling parameters. These well logging simulators help operators make informed decisions on-the-fly, optimize drilling trajectories, select logging tools, and adjust drilling parameters to maximize efficiency, minimize risks, and achieve drilling objectives.

5. Training and Education

Simulation technology is used for training and education purposes, allowing operators, technicians, and engineers to gain hands-on experience in well logging operations in a safe and controlled environment. Virtual drilling and logging simulators replicate real-world scenarios, enabling trainees to practice well logging techniques, troubleshoot problems, and improve operational skills without the need for costly field deployments.

Conclusion

Advanced technologies in well logging are driving innovation and transforming the oil and gas industry, enabling operators to unlock new reservoirs, optimize production, and mitigate environmental impacts. From wireless logging tools to real-time data analytics and environmental monitoring solutions, these innovations are reshaping the way we explore, develop, and produce hydrocarbon resources.