How Does Well Stimulation Enhance Hydrocarbon Reservoir Performance

Well stimulation is essential for maximizing recovery rates and optimizing production in both conventional and unconventional reservoirs. Well stimulation includes a range of techniques and technologies, such as matrix stimulation, acidizing, and hydraulic fracturing, aimed at enhancing reservoir performance. In this article, we delve into the science behind well stimulation, explore different techniques employed, its significance in the oil and gas industry, and how simulation technology is used in well stimulation.

What is Well Stimulation

An essential procedure in the oil and gas industry, well stimulation entails raising the flow of gas or oil from wells in order to increase the productivity of hydrocarbon reservoirs. Fundamentally, the goal of well stimulation is to increase the permeability and flow capacity of reservoir rocks in order to produce more gas and oil. Hydrocarbons are frequently confined in tight or low-permeability formations in reservoirs, making their efficient extraction difficult. Techniques for well stimulation improve reservoir connection and open up channels for fluid flow to help overcome these obstacles.

Why Well Stimulation is Important

| Significance | Description |

| Increased Production | Well stimulation techniques significantly enhance the productivity of oil and gas wells, leading to higher production rates and increased recovery of hydrocarbons. |

| Economic Viability | By maximizing well productivity, well stimulation makes marginal or uneconomic fields financially viable, thus maximizing the economic value of hydrocarbon reserves. |

| Technological Innovation | Continued advancements in well stimulation technologies drive innovation in the oil and gas industry, leading to improved efficiency and cost-effectiveness of production operations. |

| Energy Security | Well stimulation enables access to previously untapped hydrocarbon resources, contributing to energy security by reducing dependence on imported oil and gas. |

| Environmental Considerations | Well stimulation activities face environmental scrutiny due to concerns such as groundwater contamination and induced seismicity, necessitating responsible development practices. |

What are the Key Techniques of Well Stimulation

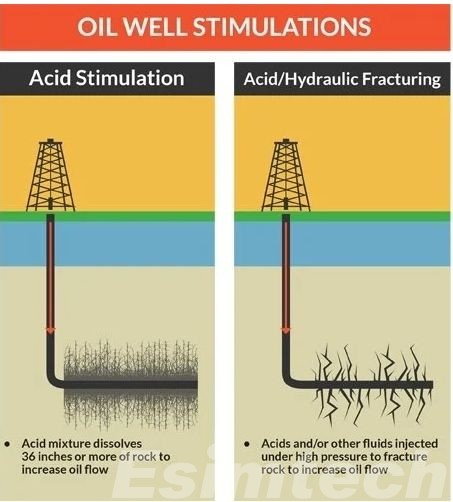

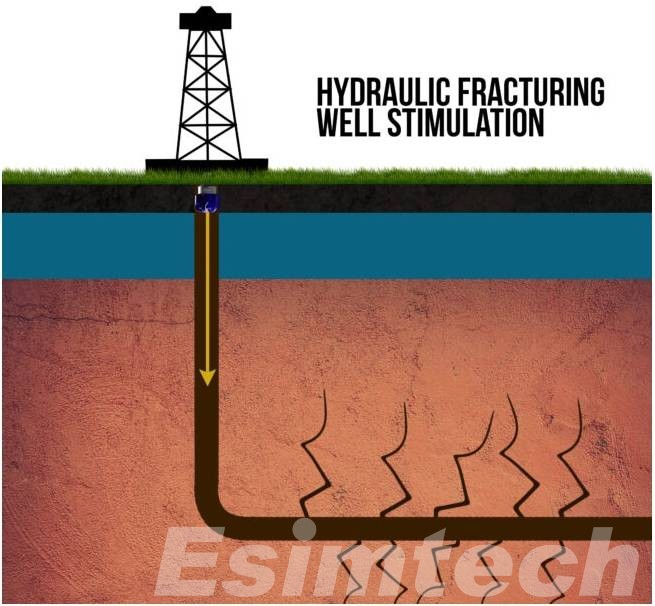

1. Hydraulic Fracturing (Fracking)

This is conceivably the most popular and extensively applied well stimulation method. By injecting a high-pressure fluid (usually water combined with sand and chemicals) into the reservoir rock, hydraulic fracturing makes fractures that make the rock more permeable and facilitate the easier extraction of oil and gas.

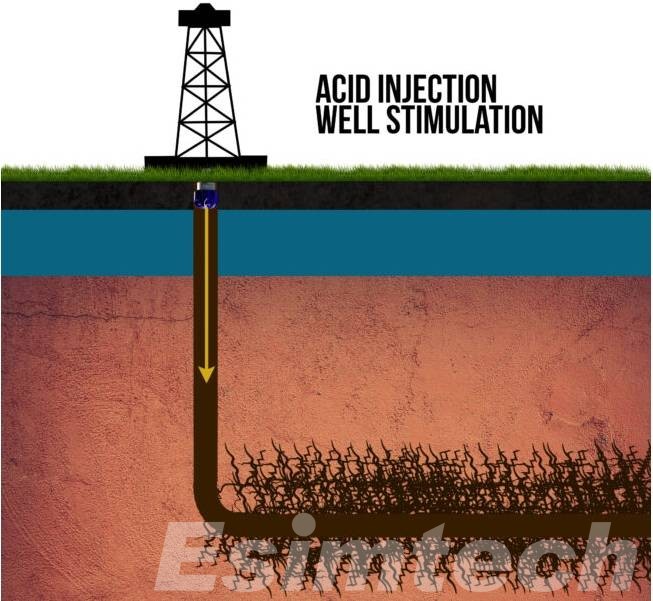

2. Acidizing

The process of "acidizing" a reservoir's rock involves dissolving substances like dolomite or limestone to open up new pores and widen old ones. Acidizing treatments include pumping acids into the wellbore, like hydrochloric acid, to dissolve the rock and increase permeability.

3. Matrix Acidizing

A type of acidizing known as matrix acidizing involves injecting acid into the reservoir rock without fracturing it. This technique is used to dissolve materials obstructing the pores within the rock matrix, thereby increasing the flow of hydrocarbons to the wellbore.

4. Acid Fracturing

Acid fracturing is a combination of hydraulic fracturing and acidizing techniques. Acid is injected into the fractures created by hydraulic fracturing to further enhance the permeability of the reservoir rock. This technique is particularly effective in carbonate formations.

5. Acid Fracture Diversion

In this technique, acid is injected into multiple perforation clusters in a well simultaneously. The goal is to divert the acid away from the most permeable zones, allowing it to penetrate and treat less-permeable zones, thereby improving overall production.

6. Proppant Squeeze

Proppant squeeze is a method used to treat near-wellbore damage in a reservoir by injecting a slurry of proppant (typically sand) and fluid into the formation under pressure. The proppant props open the fractures created by hydraulic fracturing, preventing them from closing and maintaining enhanced permeability.

7. Surfactant Flooding

Surfactant flooding involves the injection of surfactants into the reservoir to alter the interfacial tension between oil and water, thus improving the displacement of oil from the reservoir rock and enhancing production.

8. CO2 Injection

In order to improve oil recovery, carbon dioxide (CO2) injection entails pumping CO2 into the reservoir. This causes the oil to swell, lose viscosity, and migrate toward the producing wells. Projects involving enhanced oil recovery (EOR) frequently employ this technology.

How Simulation Technology Used in Well Stimulation

Simulation technology is integral to the planning, optimization, and execution of well stimulation operations in the oil and gas industry.

1. Reservoir Modeling

Detailed models of the reservoir are created using simulation software, which incorporates geological data, fluid characteristics, and wellbore configurations. The behavior of hydrocarbons inside the reservoir, pressure variations, and fluid flow dynamics are all simulated by these models. Through the execution of multiple scenarios, engineers are able to forecast the reservoir's reaction to stimulation treatments and adjust the design accordingly.

2. Hydraulic Fracturing Design

Simulation tools are used to design hydraulic fracturing treatments by modeling the propagation of fractures within the reservoir rock. Engineers input parameters such as formation properties, well geometry, fluid viscosity, and pumping rates to simulate the fracturing process. These fracturing simulations help in optimizing fracture dimensions, orientation, and spacing to maximize production while minimizing costs and environmental impact.

3. Acidizing Treatments

Simulation technology is employed to design acidizing treatments by modeling the interaction between the acid and the reservoir rock. Engineers input parameters such as acid concentration, rock composition, and treatment duration to simulate acid penetration and dissolution of formation damage. These simulations aid in optimizing acidizing treatments to enhance well productivity and reservoir performance.

4. Fluid Flow Analysis

Computational fluid dynamics (CFD) simulations are utilized to analyze fluid flow within the wellbore and reservoir during stimulation operations. These simulations predict pressure drops, fluid distribution, and flow behavior, helping engineers optimize pumping schedules, fluid properties, and wellbore configurations for effective stimulation.

5. Geomechanical Considerations

Simulation technology is used to assess the geomechanical aspects of well stimulation, including reservoir stresses, rock failure mechanisms, and induced seismicity. Geomechanical simulations help in optimizing well placement, perforation strategies, and treatment parameters to minimize risks such as formation damage, casing failure, and unwanted fractures.

6. Real-Time Monitoring and Control

Advanced oil and gas simulation tools are integrated with real-time monitoring systems to provide continuous feedback during stimulation operations. Engineers can compare real-time data with simulation predictions to adjust treatment parameters in real time, optimize stimulation effectiveness, and mitigate operational risks.

Conclusion

Well stimulation is a essential aspect of hydrocarbon production, which makes it possible to extract gas and oil from subterranean reservoirs effectively. Through the application of advanced techniques and adhering to stringent environmental standards, the energy industry can harness the potential of well stimulation while minimizing its environmental impact.

With the use of simulation technology, engineers are able to optimize, plan, and execute well stimulation operations in a way that maximizes production, reduces costs, and guarantees the safe and effective recovery of hydrocarbons from the reservoir.