How VR-based Oil Rig Simulators Reshape Oil and Gas Training

As the oil and gas industry continues to advance with digital transformation, Virtual Reality (VR) has emerged as a powerful tool for workforce development, particularly in training for complex, high-risk environments like offshore oil rigs. VR-based oil rig simulators offer a level of realism and interactivity that traditional training methods cannot match, enabling immersive learning experiences that improve safety, performance, and operational readiness.

The Need for Advanced Training Solutions

In the high-risk oil and gas industry, traditional training approaches are increasingly insufficient. Drilling operations are becoming more complex due to technological advancements, deeper wells, and harsher environments. Workers are required to master not only intricate technical processes but also to make quick, informed decisions under pressure. However, classroom-based instruction, paper manuals, and limited field exposure often leave a gap between theoretical knowledge and operational readiness.

Conventional methods struggle to simulate the high-stakes conditions workers regularly face—such as equipment failures, sudden blowouts, or extreme weather impacts. These scenarios are difficult, if not impossible, to recreate in a safe training environment. Consequently, new hires and even experienced personnel may find themselves underprepared when confronted with real-world emergencies. Moreover, physical simulators, while useful, are expensive to maintain and lack the adaptability to cover a broad range of evolving situations.

This skills gap is further exacerbated by a generational shift in the workforce. As seasoned professionals retire, a younger, tech-savvy generation is entering the field. These digital natives respond better to immersive, interactive learning than to static instructional models. Their learning expectations align with technologies like VR, which offer hands-on engagement, instant feedback, and repeatable, scenario-based learning.

The industry is therefore under mounting pressure to adopt advanced training solutions that can deliver realism, scalability, and safety—all while reducing cost and training time. VR-based oil rig simulators emerge as an ideal answer to this challenge. They enable safe exposure to hazardous conditions, foster quick decision-making, and ensure consistent skill development across global training centers. The result is a better-prepared, more confident workforce ready to operate in the demanding world of energy exploration.

What are VR-based Oil Rig Simulators

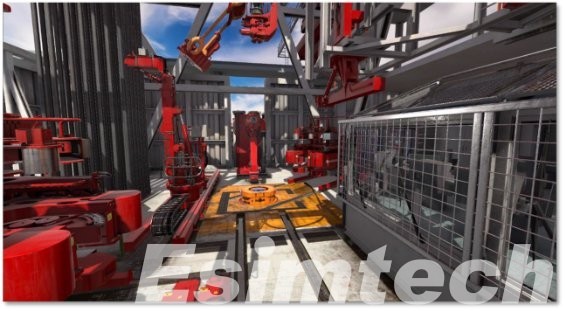

VR-based oil rig simulators are immersive training systems that use virtual reality technology to replicate the physical and operational environment of an oil rig. These simulators provide a 360-degree, interactive experience that allows trainees to engage with realistic, high-fidelity virtual scenarios as if they were physically present on a drilling platform. By using head-mounted displays, motion sensors, and handheld controllers, users can perform rig operations, navigate the structure, and respond to complex challenges in real time.

These systems are developed with detailed 3D modeling and physics-based simulations to mirror actual rig behavior. From manipulating drill strings to managing mud circulation and responding to kick warnings, the simulator reproduces authentic workflows and pressure dynamics. Trainees can walk through rig floors, operate control panels, and even coordinate with virtual crew members in simulated emergencies, such as well blowouts or gas leaks. The environments are often designed to include auditory cues, machine vibrations, and visual alerts, contributing to a deeply immersive sensory experience.

Unlike traditional training tools, VR oil rig simulators are not constrained by physical limitations or safety risks. They allow users to repeatedly practice procedures, make errors, and learn from those mistakes without any real-world consequences. This promotes better knowledge retention, critical thinking, and confidence in executing high-risk tasks.

Moreover, the adaptability of VR technology means that simulations can be updated to reflect changes in equipment, regulations, or best practices. Training can be personalized based on individual skill levels, and performance metrics can be tracked for assessment and improvement. This makes VR-based oil rig simulators not just a modern learning tool but a strategic asset in building a competent, safety-conscious workforce for the future of energy exploration.

Benefits of VR-based Oil Rig Simulators

The integration of virtual reality into oil rig training brings a host of transformative benefits, fundamentally changing how the industry prepares its workforce for high-risk environments.

- Enhanced Safety

VR-based oil rig simulators allow trainees to experience and respond to hazardous scenarios—such as blowouts, equipment failures, or fire emergencies—without ever being in danger. This safe environment encourages active learning and builds the confidence needed to respond effectively in real situations.

- Realistic, Hands-on Learning

Traditional classroom methods often fail to engage trainees or provide context for critical tasks. VR oil rig simulators immerse users in lifelike rig environments where they can interact with tools, systems, and procedures. This experiential learning model leads to better retention of knowledge, sharper problem-solving skills, and stronger operational readiness.

- Cost-effectiveness

Operating a physical training rig or coordinating offshore training exercises can be prohibitively expensive and logistically complex. VR training simulator eliminates the need for travel, reduces downtime, and minimizes the costs associated with equipment use and wear. Furthermore, once developed, simulations can be reused and updated with minimal overhead.

- Personalized and Scalable Training

Programs can be adapted to various skill levels, from green recruits to seasoned engineers. Individual performance data—such as reaction times, decision accuracy, and procedural adherence—can be tracked and analyzed to customize training paths and identify areas for improvement.

- Team-based Learning and Collaboration

Multi-user VR environments allow teams to train together, practice communication during crisis scenarios, and refine their coordination. This is especially important in a field where teamwork and precise timing often mean the difference between safety and disaster.

Application Scenarios of VR-based Oil Rig Simulators

- Offshore Rig Familiarization: New employees or contractors can be virtually introduced to the layout, equipment, and safety zones of offshore platforms such as jack-up rigs, semi-submersibles, and drillships. This familiarization helps reduce anxiety and boosts confidence before they step foot on a real rig.

- Emergency Response Training: VR oil rig simulations replicate critical emergency scenarios like gas leaks, fires, explosions, and helicopter ditching events. Trainees learn how to react under pressure, follow evacuation procedures, and make time-sensitive decisions without risk to life or equipment.

- Well Control and Blowout Prevention: VR-based oil rig simulator can replicate kick detection, shut-in procedures, and the operation of blowout preventers (BOPs). This hands-on experience enhances the technical competency of drillers and toolpushers, particularly in deepwater or high-pressure/high-temperature (HPHT) environments.

- Crane and Lifting Operations: Crane operators and deck crew can be trained to handle complex lifting scenarios, including load balancing, poor weather conditions, and communication protocols with rig floor personnel. VR reduces the chance of costly lifting accidents by improving spatial awareness and coordination.

- Equipment Handling and Maintenance: Trainees can learn the correct methods for assembling, inspecting, and maintaining complex machinery such as top drives, rotary tables, mud pumps, and derricks. VR modules help build muscle memory and procedural discipline without interrupting real-world operations.

- Drilling and Control Room Operations: Drilling engineers and rig supervisors can practice operating virtual control panels and data monitoring systems. Oil rig simulators replicate fluctuating downhole pressures, drilling fluid properties, and real-time system feedback to hone decision-making and critical thinking.

- Team-Based Operational Drills: Multi-user VR environments allow teams to collaborate on rig operations and emergency drills. This promotes communication, coordination, and leadership training under realistic conditions, mirroring the complexities of working in high-stakes offshore environments.

- Regulatory Compliance and Safety Certification: Many training programs now require certification in safety and operational standards (e.g., IWCF, OPITO). VR simulators help organizations meet these requirements efficiently by offering standardized, audit-ready modules with performance tracking and repeatability.

Esimtech is a leading provider of advanced virtual reality simulators for the oil and gas industry, specializing in immersive training solutions for drilling operations. These drilling and well control simulators offer realistic, risk-free environments where trainees can engage with complex equipment and emergency scenarios, enhancing their operational proficiency and safety awareness.

Challenges and Future Directions in VR-based Oil Rig Simulators

| Challenge | Description | Future Direction |

| High Initial Costs | Developing high-quality VR simulations and acquiring equipment requires significant upfront investment. | Adoption of cloud-based VR platforms and shared training hubs to reduce entry costs. |

| Limited Tactile Feedback | Current VR systems primarily engage visual and auditory senses, lacking physical realism. | Integration of advanced haptic devices to simulate touch and resistance. |

| User Discomfort and Fatigue | Prolonged use of headsets can cause eye strain, motion sickness, or physical fatigue. | Development of lightweight, ergonomic VR gear and shorter, modular training sessions. |

| Simulating Realistic Human Behavior | It’s challenging to mimic nuanced human actions and interactions in team-based scenarios. | AI-driven virtual characters to improve realism in team training and communication. |

| Content Maintenance and Updates | Frequent equipment and protocol changes require ongoing updates to training modules. | Modular content design for faster and easier updates with minimal disruption. |

| Workforce Resistance to New Technology | Some workers, particularly those less tech-savvy, may be hesitant to adopt VR-based learning. | Blended learning models combining VR with familiar methods to ease the transition. |

| Connectivity Constraints for Remote Access | VR training at remote sites can be limited by internet speed and infrastructure gaps. | Offline-capable VR modules and optimization for low-bandwidth environments. |

Final Thoughts

VR-based oil rig simulators represent a revolutionary step in workforce development for the oil and gas sector. By combining immersive experiences with data-driven training analytics, the oil simulator prepares workers for real-world rig challenges more effectively and safely than ever before. As the industry seeks to balance operational efficiency with safety and sustainability, virtual reality oil rig simulation training solutions will play an increasingly critical role.