Innovative Strategies for Snubbing Units in Challenging Environments

In the oil and gas operations, encountering challenging environments is par for the course. From remote locations with extreme temperatures to high-pressure wells and volatile conditions, the industry demands equipment that can rise to the occasion. In such an environment, snubbing units emerge as indispensable tools, playing a pivotal role in well intervention and completion activities, especially in environments where conventional methods fall short. Let’s delve into the world of snubbing units and how they tackle challenges head-on in demanding environments.

Understanding Snubbing Units

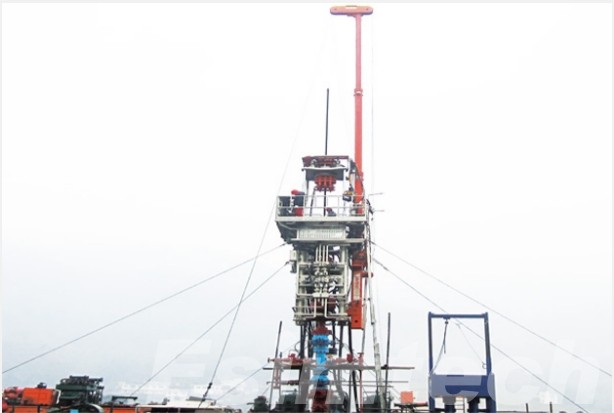

At its core, a snubbing unit is a hydraulic or pneumatic-powered rig used to insert or remove tubulars from a wellbore while maintaining well control. Unlike conventional workover rigs, snubbing units operate under pressure, allowing them to work on live wells without the need for well kill operations. This capability makes them invaluable for interventions in wells with high pressures or complex downhole conditions.

Navigating Challenging Environments with Snubbing Units

1. Extreme Temperatures

In regions with scorching heat or bone-chilling cold, snubbing units must withstand a wide range of temperatures while maintaining operational efficiency. Specialized insulation, heating, or cooling systems are often integrated into the unit design to ensure performance in extreme climates.

2. High-Pressure Wells

Snubbing units excel in high-pressure environments where traditional workover rigs may struggle. By utilizing hydraulic or pneumatic force to control the wellbore pressure, these units can safely perform interventions in wells with elevated pressures, minimizing the risk of blowouts or other catastrophic events.

3. Remote Locations

Oil and gas exploration often takes operators to remote and inaccessible locations, where infrastructure is limited, and logistical challenges abound. Portable and modular snubbing units are designed to be transportable and adaptable, allowing them to be deployed quickly and efficiently in remote areas without compromising on performance.

4. Hazardous Conditions

Oilfield operations inherently involve working with volatile substances and hazardous environments. Snubbing units are equipped with advanced safety features and redundant systems to mitigate risks and ensure the safety of personnel and assets. Rigorous training and adherence to strict safety protocols further enhance safety in challenging conditions.

Key Innovations that are Driving Efficiency for Snubbing Units in Challenging Environments

In challenging environments, where the stakes are high and conditions are unpredictable, innovations are essential for enhancing the efficiency and effectiveness of snubbing units.

1. Advanced Hydraulic Systems

- Enhanced hydraulic systems are crucial for providing the power and control needed to operate snubbing units effectively in challenging environments. These systems incorporate high-pressure pumps, valves, and actuators designed to withstand extreme conditions and deliver precise and reliable performance.

- Innovations in hydraulic technology include the development of high-performance seals and components that can withstand high temperatures, corrosive fluids, and abrasive materials commonly encountered in oil and gas operations.

2. Automated Control Systems

- Automated control systems play a significant role in improving the efficiency and safety of snubbing operations in challenging environments. These systems use sensors, actuators, and advanced algorithms to monitor and control key parameters such as pressure, temperature, and position.

- By automating repetitive tasks and providing real-time feedback, automated control systems reduce the risk of human error, enhance operational efficiency, and improve the overall safety of snubbing operations.

3. Integrated Telemetry and Monitoring Solutions

- Telemetry and monitoring solutions enable operators to gather real-time data on the performance of snubbing units and the conditions inside the wellbore. These solutions use sensors, data acquisition systems, and communication networks to collect and transmit data to control centers for analysis.

- By providing operators with insights into critical parameters such as pressure, temperature, and flow rates, telemetry and monitoring solutions enable proactive decision-making, optimization of operations, and early detection of potential issues.

4. Modular and Portable Designs

- Modular and portable designs make snubbing units more versatile and adaptable to challenging environments. These designs enable snubbing units to be transported to remote locations and deployed quickly and efficiently, reducing downtime and logistical challenges.

- Innovations in modular design include the use of lightweight materials, compact configurations, and modular components that can be easily assembled and disassembled in the field.

5. Remote Operation Capabilities

- Remote operation capabilities allow snubbing units to be controlled and monitored from a centralized location, reducing the need for personnel to be physically present at the wellsite. Remote operation systems use secure communication networks and advanced control interfaces to enable operators to remotely control snubbing operations and monitor performance in real-time.

- By minimizing the need for personnel to be exposed to hazardous environments and reducing travel time and costs, remote operation capabilities improve safety, efficiency, and operational flexibility in challenging environments.

How Simulation Technology Used for Snubbing Units in Challenging Environments

Simulation technology plays a vital role in optimizing the performance, safety, and efficiency of snubbing units in challenging environments within the oil and gas industry.

1. Training and Skill Development

- Snubbing simulators provide realistic virtual environments where operators can undergo training and skill development for operating snubbing units in challenging conditions.

- Operators can practice various scenarios, including high-pressure well interventions and well control procedures, allowing them to familiarize themselves with equipment operation and emergency response protocols.

2. Equipment Performance Assessment

- Simulation models are used to assess the performance of snubbing unit components and systems under different operating conditions.

- Engineers can simulate the behavior of hydraulic, pneumatic, and mechanical systems to identify potential issues, optimize designs, and ensure the reliability and efficiency of equipment in challenging environments.

3. Dynamic Pressure Control Analysis

- Simulation technology enables operators to analyze dynamic pressure control scenarios, such as well kicks or blowouts, in virtual environments.

- By simulating pressure responses, fluid dynamics, and wellbore behavior, operators can evaluate the effectiveness of pressure control equipment and procedures, identify potential risks, and develop contingency plans to maintain well control.

4. Wellbore Modeling and Analysis

- Simulation models are used to create detailed representations of wellbores and downhole conditions, including pressure, temperature, fluid properties, and formation characteristics.

- By simulating wellbore behavior in real-time, engineers can optimize operational parameters, such as pressure control strategies and tubular movement, to ensure safe and efficient interventions in challenging environments.

5. Safety and Risk Assessment

- Simulation technology facilitates safety and risk assessments for snubbing operations in challenging environments.

- Operators can simulate potential hazards, equipment failures, and emergency scenarios to identify risks, evaluate the effectiveness of safety protocols, and develop mitigation strategies to minimize the likelihood of accidents and ensure the safety of personnel and assets.

Conclusion

Snubbing units are essential assets in the oil and gas industry, particularly in challenging environments where conventional methods may be insufficient. With their ability to operate under pressure, withstand extreme conditions, and adapt to remote locations, these units enable operators to carry out interventions safely and efficiently, even in the most demanding circumstances.