Microbial Enhanced Oil Recovery: Innovative Solution to Oil Extraction from Reservoirs

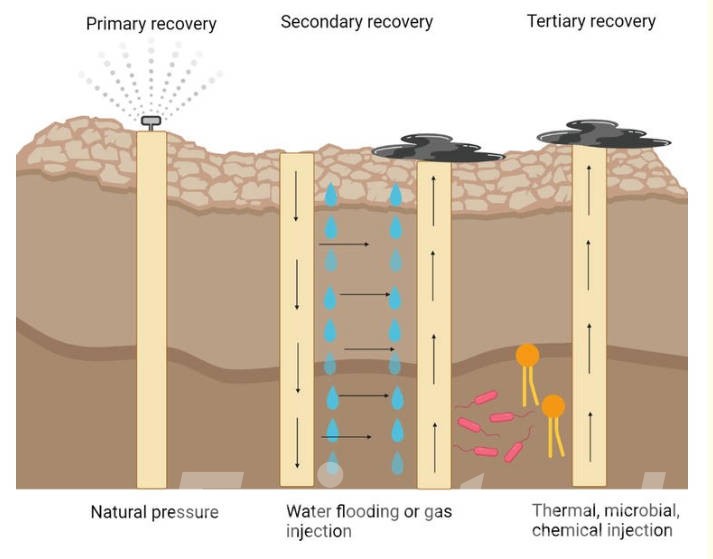

Microbial Enhanced Oil Recovery (MEOR) is an innovative and eco-friendly approach to extracting oil from reservoirs that traditional methods can no longer efficiently exploit. As conventional oil recovery methods often leave a significant portion of the oil trapped in the reservoir, Microbial Enhanced Oil Recovery offers a promising solution to enhance oil recovery, extend the life of oil fields, and reduce environmental impacts.

What is Microbial Enhanced Oil Recovery

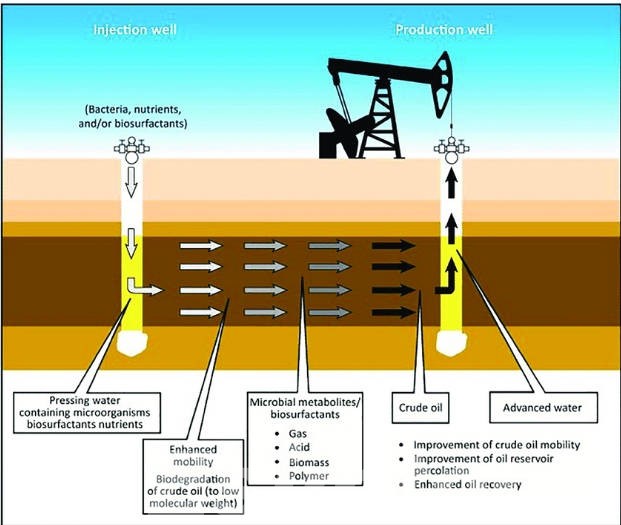

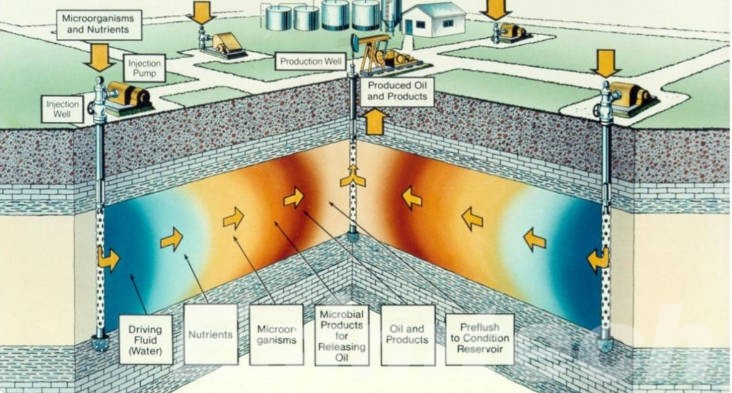

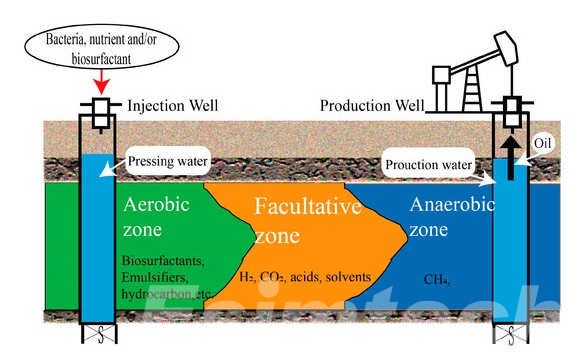

Microbial Enhanced Oil Recovery involves the use of microorganisms and their metabolic byproducts to mobilize and extract oil from reservoirs. By injecting specific microbes or nutrients into the oil field, these microbes can alter the properties of the oil, water, or the reservoir rock to facilitate enhanced oil recovery.

Key Processes in Microbial Enhanced Oil Recovery

1. Biopolymer Production

Mechanism

- Certain microbes produce biopolymers, such as xanthan gum or scleroglucan, during their metabolic processes.

Function

- Increased Water Viscosity: Biopolymers increase the viscosity of the water used in water flooding, improving its ability to displace oil.

- Improved Sweep Efficiency: By increasing water viscosity, biopolymers help ensure a more uniform displacement of oil, reducing the likelihood of water bypassing oil-rich zones.

Benefits

- Enhances the efficiency of water flooding by improving the contact between the displacing water and the oil, leading to higher oil recovery rates.

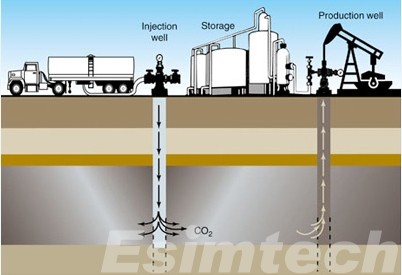

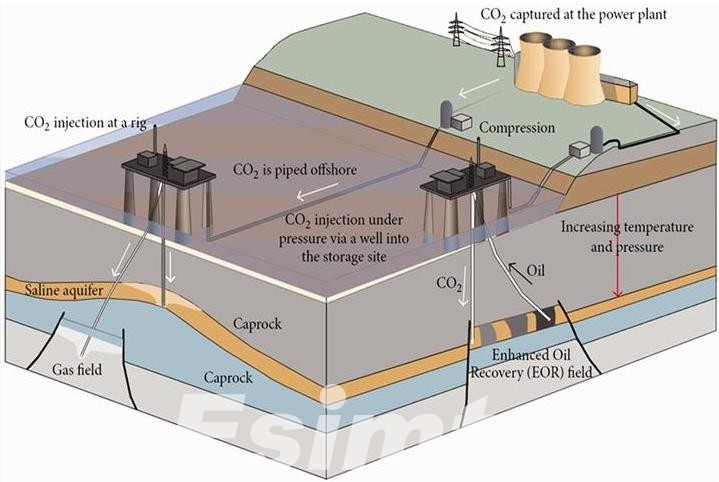

2. Biogas Production

Mechanism

- Microbes, particularly anaerobic bacteria, produce gases such as carbon dioxide (CO₂), methane (CH₄), and hydrogen (H₂) through fermentation and other metabolic activities.

Function

- Increased Reservoir Pressure: The production of gases increases the pressure within the reservoir, aiding in the displacement of oil.

- Reduced Oil Viscosity: The dissolution of gases like CO₂ in the oil can reduce its viscosity, making it easier to flow towards production wells.

Benefits

- Enhances oil recovery by improving reservoir pressure and reducing the physical barriers to oil flow.

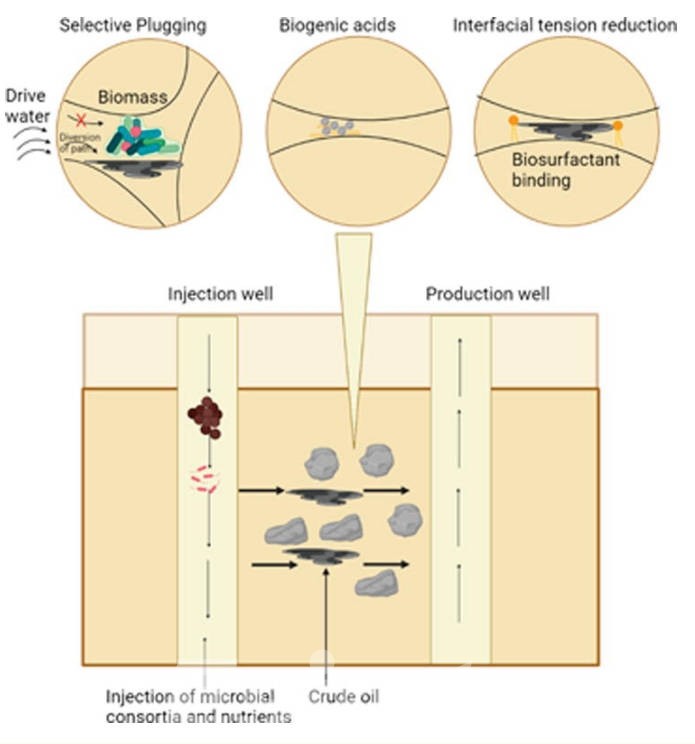

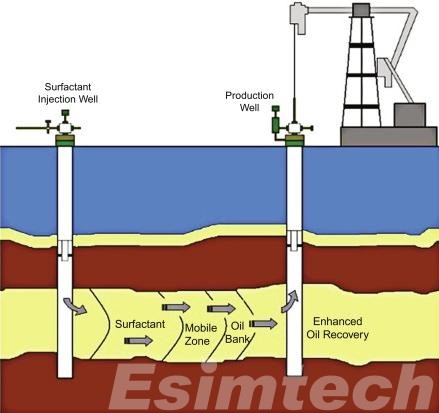

3. Biosurfactant Production

Mechanism

- Microorganisms, such as Pseudomonas species, produce biosurfactants during their growth.

Function

- Reduced Interfacial Tension: Biosurfactants decrease the interfacial tension between oil and water, which helps to mobilize trapped oil droplets.

- Wettability Alteration: Biosurfactants can also change the wettability of the reservoir rock, making it more water-wet and facilitating the flow of oil.

Benefits

- Significantly improves the mobility of oil, enabling it to move more freely through the reservoir towards the production well.

4. Bioclogging

Mechanism

- Microbial growth can selectively clog high-permeability zones within the reservoir.

Function

- Selective Plugging: By clogging high-permeability zones, microbes can divert the flow of injected water to lower permeability, oil-rich areas that are typically bypassed during conventional water flooding.

Benefits

- Enhances the overall sweep efficiency of water floods, ensuring that more of the reservoir is contacted by the displacing fluid, thereby increasing oil recovery.

5. Microbial Degradation of Oil

Mechanism

Certain microbes, such as those from the genera Bacillus and Clostridium, can partially degrade heavy hydrocarbons.

Function

- Viscosity Reduction: The partial degradation of heavy oil components results in a reduction of oil viscosity.

- Enhanced Mobility: Lower viscosity oil flows more easily through the reservoir, improving its recoverability.

Benefits

Facilitates the extraction of heavy and viscous oils that are otherwise difficult to produce using conventional methods.

Types of Microbial Enhanced Oil Recovery

1. In-Situ Microbial Enhanced Oil Recovery

- Description: Microorganisms and nutrients are directly injected into the reservoir. Indigenous or injected microbes thrive and produce beneficial byproducts in the subsurface environment.

- Application: Suitable for reservoirs where in-situ conditions (temperature, pressure, salinity) are conducive to microbial activity.

2. Ex-Situ Microbial Enhanced Oil Recovery

- Description: Microbial products (e.g., biosurfactants, biopolymers) are produced in bioreactors on the surface and then injected into the reservoir.

- Application: Allows for greater control over the quality and quantity of microbial byproducts introduced into the reservoir.

Challenges and Limitations in Microbial Enhanced Oil Recovery

1. Reservoir Conditions

Variability in Reservoir Environments

Oil reservoirs vary significantly in terms of temperature, pressure, salinity, and the types of oil they contain. These conditions can affect microbial activity and the production of metabolites necessary for Microbial EOR.

High Temperature and Pressure

Many oil reservoirs are located at depths where temperatures and pressures are extreme. Most microbes have optimal growth conditions that are far less harsh, making it challenging to find or engineer strains that can survive and remain active in such environments.

Salinity and pH Levels

High salinity and extreme pH levels in some reservoirs can inhibit microbial growth and activity. Identifying or engineering salt-tolerant and pH-resistant microbial strains is necessary for Microbial Enhanced Oil Recovery in such conditions.

2. Microbial Selection and Adaptation

Selecting Appropriate Microbes

Choosing the right microbial strains that can produce the desired bioproducts (e.g., biosurfactants, biopolymers) and thrive in specific reservoir conditions is a complex and time-consuming process.

Adaptation to Reservoir Conditions

Microbes introduced into the reservoir must adapt to the subsurface environment, which may involve significant physiological changes. Ensuring that these microbes remain active and effective over time is a key challenge.

Genetic Stability

Maintaining the genetic stability of engineered or selected microbial strains in the reservoir environment is critical to ensure consistent production of metabolites.

3. Nutrient Supply and Delivery

Sustaining Microbial Activity

Microbes require nutrients to grow and produce metabolites. Ensuring a continuous and adequate supply of nutrients in the reservoir is challenging, especially in heterogeneous reservoirs where nutrient distribution can be uneven.

Nutrient Costs and Logistics

The cost and logistics of delivering nutrients to the reservoir can be significant. Designing efficient nutrient delivery systems that minimize costs and maximize effectiveness is essential.

4. Monitoring and Control

Tracking Microbial Activity

Monitoring microbial growth, distribution, and metabolite production in the subsurface environment is difficult. Advanced monitoring technologies are needed to track these parameters in real-time.

Control of Microbial Processes

Ensuring that microbial processes are controlled and sustained over the long term requires sophisticated management strategies. This includes managing nutrient supply, monitoring environmental conditions, and adjusting injection protocols as needed.

5. Economic Viability

High Initial Costs Microbial Enhanced Oil Recovery

The research, development, and implementation of technologies involve significant initial costs. This includes costs related to microbial strain development, field trials, and nutrient delivery systems.

Uncertain Returns on Investment

The economic benefits of Microbial Enhanced Oil Recovery can be uncertain, particularly in volatile oil markets. Oil prices can influence the cost-effectiveness of Microbial EOR projects, making it crucial to conduct thorough economic evaluations before implementation.

Scale-Up Challenges

Scaling up MEOR from laboratory and pilot studies to full-field applications presents numerous technical and logistical challenges. Ensuring that the processes are effective on a larger scale requires comprehensive planning and testing.

6. Environmental and Regulatory Concerns

Environmental Impact

While microbial EOR is generally considered environmentally friendly compared to chemical and thermal methods, the introduction of microbes and nutrients into the subsurface environment must be managed carefully to avoid unintended ecological impacts.

Regulatory Compliance

Microbial EOR projects must comply with various environmental regulations and standards. Navigating the regulatory landscape can be complex and time-consuming, requiring thorough documentation and adherence to guidelines.

Case Studies and Field Applications of Microbial Enhanced Oil Recovery

1. Daqing Oil Field, China

One of the largest and most successful applications of MEOR. The use of biosurfactant-producing microbes significantly increased oil production, demonstrating the practical benefits of Microbial EOR.

2. Wasson Oil Field, USA

Microbial EOR techniques involving biopolymer-producing microbes were employed to enhance oil recovery in this mature field, resulting in notable improvements in production rates.

3. North Sea Fields

Various Microbial Enhanced Oil Recovery projects have been undertaken in the North Sea, showing promising results in enhancing oil recovery from offshore reservoirs.

Future Prospects in Microbial Enhanced Oil Recovery

The future of Microbial Enhanced Oil Recovery is shaped by advancements in biotechnology, microbiology, and reservoir engineering, alongside increasing environmental and economic pressures. Here are some key areas where future developments are expected to drive the growth and effectiveness of Microbial EOR.

1. Advanced Microbial Engineering

Genetic and Metabolic Engineering

- Enhanced Microbial Strains: Advances in genetic engineering and synthetic biology will enable the creation of microbial strains that are optimized for specific reservoir conditions. These engineered microbes can be tailored to produce higher yields of biosurfactants, biopolymers, and other useful metabolites.

- Robustness and Adaptability: Genetic modifications can enhance the robustness of microbes, allowing them to withstand extreme reservoir conditions such as high temperature, pressure, and salinity.

Synthetic Biology

- Custom Metabolic Pathways: Synthetic biology can be used to design custom metabolic pathways in microbes, enhancing their ability to produce desired byproducts. This could include the development of microbes that can produce novel biosurfactants or biopolymers not found in nature.

- Bioaugmentation: Introducing synthetic consortia of microbes with complementary functions could improve the overall efficiency of MEOR processes.

2. Integrated Microbial Enhanced Oil Recovery Techniques

Combination with Other EOR Methods

- Hybrid Approaches: Combining MEOR with other Enhanced Oil Recovery (EOR) techniques, such as chemical, thermal, or gas injection methods, can create synergistic effects. For example, microbial biosurfactants could be used in conjunction with chemical surfactants to further reduce interfacial tension and enhance oil mobilization.

- Sequential Processes: Implementing sequential EOR processes, where MEOR is used after primary and secondary recovery methods, can maximize oil extraction efficiency.

3. Improved Reservoir Characterization and Modeling

Advanced Reservoir Simulation

- Predictive Modeling: Developments in computational modeling and simulation can improve the prediction of microbial behavior and metabolite distribution within reservoirs. This oil and gas simulation system allows for better planning and optimization of Microbial Enhanced Oil Recovery strategies.

- Reservoir Characterization: Enhanced techniques for reservoir characterization, such as 3D seismic imaging and microseismic monitoring, can provide detailed information about reservoir heterogeneity and guide the placement of microbial injections.

Real-Time Monitoring

- Microbial Sensors: Innovations in sensor technology can enable real-time monitoring of microbial activity, metabolite production, and reservoir conditions. This data can be used to adjust MEOR processes dynamically for optimal performance.

- Data Analytics and AI: The integration of artificial intelligence and machine learning can help analyze large datasets from Microbial EOR operations, providing insights and recommendations for improving efficiency and effectiveness.

- Real-Time Optimization: Implementing real-time monitoring and control systems that adjust Microbial Enhanced Oil Recovery processes dynamically based on ongoing performance data and predictive oil recovery simulations.

4. Sustainable and Environmentally Friendly Practices

Green Biotechnology

- Eco-Friendly Microbes: Development of environmentally benign microbial strains that do not produce harmful byproducts can mitigate potential ecological impacts of Microbial EOR.

- Biodegradable Nutrients: Using biodegradable nutrients and additives can further reduce the environmental footprint of MEOR operations.

Regulatory Compliance and Public Acceptance

- Regulatory Frameworks: Developing comprehensive regulatory frameworks that ensure safe and responsible use of MEOR technologies will be crucial for widespread adoption.

- Stakeholder Engagement: Engaging with local communities, environmental groups, and other stakeholders to build trust and demonstrate the benefits of MEOR can enhance public acceptance and support.

5. Economic Viability and Scalability

Cost-Effective Solutions

- Reduction in Costs: Continued research and development can lead to more cost-effective microbial strains and nutrient formulations, reducing the overall costs of Microbial Enhanced Oil Recovery

- Scalable Technologies: Developing scalable MEOR technologies that can be efficiently implemented in large-scale operations will be key to its commercial success.

Field Trials and Case Studies

- Successful Demonstrations: Conducting extensive field trials and documenting successful case studies will provide valuable data and encourage investment in MEOR technologies.

- Best Practices: Establishing best practices for Microbial Enhanced Oil Recovery implementation can help standardize processes and improve success rates across different reservoirs and conditions.

Conclusion

Microbial Enhanced Oil Recovery represents a transformative approach in the oil industry, offering a sustainable and effective solution to increase oil recovery from mature and challenging reservoirs. Despite the challenges, continued research and technological advancements are poised to unlock the full potential of Microbial EOR, paving the way for a more efficient and environmentally friendly future in oil extraction.