The Role of Oil and Gas Simulation in Achieving Net-Zero Emissions

The oil and gas industry is facing increasing pressure to reduce carbon emissions and move towards sustainable energy practices. Net-zero emissions—balancing emitted greenhouse gases with removal or offset—are a prime target. Oil and gas simulation is one of the most effective ways to help this industry meet sustainability targets. By utilizing advanced oil and gas simulation software, companies can make operations more efficient, minimize environmental impact, and accelerate the move towards cleaner energy alternatives.

What is Net-Zero Challenge in Oil and Gas?

Net zero represents one of the greatest challenges to oil and gas industries today--balancing greenhouse gas emissions with removal or offset efforts to achieve carbon neutrality. Global climate targets call for reaching net-zero by 2050, placing immense strain on energy companies to transition their operations while protecting energy security.

Transition in the oil and gas sector involves:

- Reducing operational emissions through methane leak reduction, flaring reduction, and improving energy efficiency during extraction and refining operations is paramount to environmental protection.

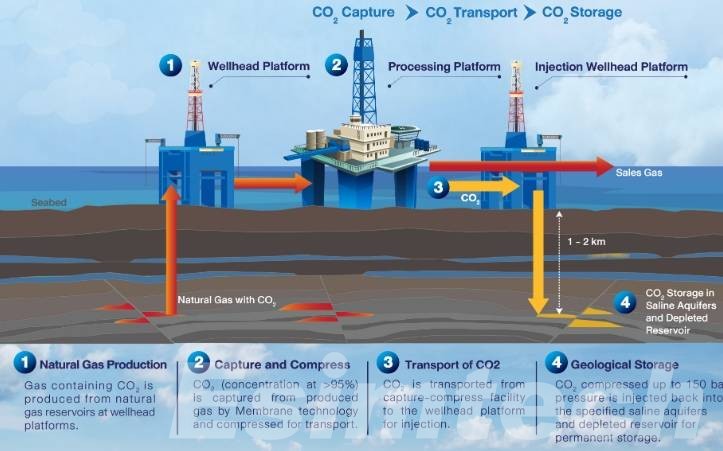

- Implement carbon capture, utilization, and storage (CCUS) techniques in order to capture CO2 before it enters the atmosphere.

- Integrating low-carbon technologies, like hydrogen production and renewable energy sources into existing operations.

- Enhance transparency through improved emissions monitoring and reporting.

However, oil and gas operations face many hurdles to decarbonization efforts, including high costs, technological limitations and large scale infrastructure changes that must take place quickly in order to be sustainable. Their operations are deeply interwoven into global energy networks making rapid decarbonization challenging without disrupting supply chains or interrupting operations.

Oil and gas simulation can play an invaluable role. By employing advanced modeling and predictive analytics techniques, companies can conduct tests of decarbonization strategies, optimize processes, accelerate innovation while mitigating risks - providing cost-effective opportunities to explore sustainable solutions before their full scale implementation, helping the industry meet net-zero commitments efficiently.

Uning the net-zero challenge requires an integrated approach involving policy support, technological developments and strategic planning--simulation being instrumental to this transformation process.

How Oil and Gas Simulation Technology Support?

The transition to net-zero emissions demands innovative solutions, and oil and gas simulation is playing a pivotal role in helping the industry meet its sustainability targets.

What is Oil and Gas Simulation?

Oil and gas simulation is a computer modeling technique that replicates energy processes in the field, ranging from production and exploration to refining and distribution. Using virtual representations of physical systems, engineers can evaluate performance, predict outcomes, and optimize operations prior to implementing changes in the field.

Advanced oil and gas simulation software uses mathematical algorithms, physics-based modeling, and data analysis to replicate complex scenarios, such as reservoir performance, fluid flow, and equipment optimization. These simulations allow firms to minimize risk, conserve funds, and become more sustainable by modeling the most efficient and ecologically responsible techniques.

Through simulation, oil and gas businesses can experiment with various strategies in a risk-free virtual world, guaranteeing more informed decision-making that underpins both profitability and net-zero emission ambitions.

Oil and Gas Simulation Technologies Involved

In order to achieve net-zero emissions, the oil and gas industry relies on high-end simulation technologies that optimize operations, reduce waste, and boost sustainability. Four of these primary oil and gas simulation technologies are behind this revolution:

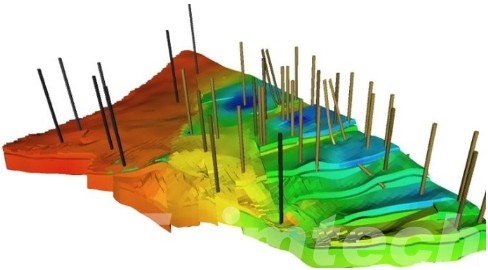

Reservoir Modeling

Reservoir simulation is a critical way of modeling subsurface oil and gas reservoirs. Through the modeling of fluid flow, pressure change, and production efficiency, engineers can maximize production with minimal environmental footprint. Next-generation oil and gas simulation software like Schlumberger's Eclipse and Halliburton's Nexus guarantees that the behavior of the reservoir can be anticipated, without unnecessary drilling and carbon emissions. The technology also facilitates enhanced oil recovery (EOR), which is a life extension of a field with minimal carbon footprint.

Carbon Capture and Refining Process Simulation

Petrochemical plants and refineries utilize software like Aspen HYSYS and CHEMCAD to simulate chemical reactions, energy use, and emissions. These tools allow them to streamline the burning of their fuel, minimize flaring, and maximize carbon capture and storage (CCS) facilities. By testing different scenarios of refining, enterprises can identify the most effective way of saving energy, lowering greenhouse gas emissions in fact.

Real-Time Monitoring with Digital Twins

A digital twin is an online copy of physical assets—such as pipelines, rigs, or processing plants—that evolves in real time according to IoT sensors and AI. Digital twins enable predictive maintenance, early methane leak detection, and improved operational efficiency. Shell and BP, among other companies, use digital twins to monitor emissions to achieve net-zero requirements while preventing costly downtime.

Interactive Training Simulations for Safety & Efficiency

Human error leads to operational inefficiencies and safety risks, increasing emissions. Virtual reality (VR) and augmented reality (AR) simulation training prepare workers for challenging tasks—such as shutdowns in the event of emergencies or equipment repair—without real risk. ExxonMobil uses VR simulations to train employees in low-carbon operations, reducing accidents and energy consumption.

These oil and gas simulation technologies play a vital role in reducing emissions, increasing efficiency, and accelerating the path toward a low-carbon energy future.

Benefits of Oil and Gas Simulation for Sustainability

Let's face it--oil and gas industry isn't going away overnight, but its impact can certainly reduce. That's where oil and gas simulation comes into play - think of it like a high-tech crystal ball that helps companies cut emissions, waste less energy, and even prep for a future with more renewables. Here’s how it’s making a difference:

1. Slash Emissions

No one wants to add CO2 into the air, yet stopping operations completely is not feasible. Simulation allows companies to test different drilling, refining and transport methods first in a virtual setting before spending money and emitting emissions in reality. They can find an approach with minimum emissions before actually spending any cash for real.

2. Stop Methane Leaks Before They Happen

Methane leaks can be an enormous waste of resources; but with digital twin technology engineers can now monitor pipelines and equipment real time to spot vulnerable points before leakage happens - meaning fewer leaks and happier planet overall!

3. Enhancing Carbon Capture Shrewder

Carbon capture and storage (CCS) may seem appealing, but finding safe storage places for CO2 may prove more complex than anticipated. Simulation models underground rock formations to find safest locations where all that carbon stays buried underground versus in the air.

4. Helps Transition Into Renewables

Moving toward hydrogen or solar power? Simulation allows businesses to easily transition by testing how these new sources interact with existing infrastructure - no more guesswork involved, just smooth transitions!

5. Saves Money while Protecting the Planet

Sustainability can save money as well. Through simulation processes, energy waste is cut significantly while downtime and mistakes are reduced significantly - not only is going green a great PR opportunity - it's good business too!

Oil and gas simulation software goes beyond simply keeping the lights burning; rather, its aim should be to ensure they burn cleaner, smarter, and cheaper - something which benefits all involved parties involved in oil and gas operations.

In General

The path to net-zero emissions in the oil and gas industry is complex, but oil and gas simulation provides the precision and foresight needed to navigate it. By utilizing cutting-edge oil and gas simulation software, companies can reduce waste, enhance efficiency, and accelerate the adoption of cleaner energy solutions. As the industry evolves, simulation will remain a cornerstone of sustainable innovation.

Investing in these technologies today ensures a more environmentally responsible tomorrow.