Top 5 Innovations in Shale Gas Drilling You Need to Know in 2025

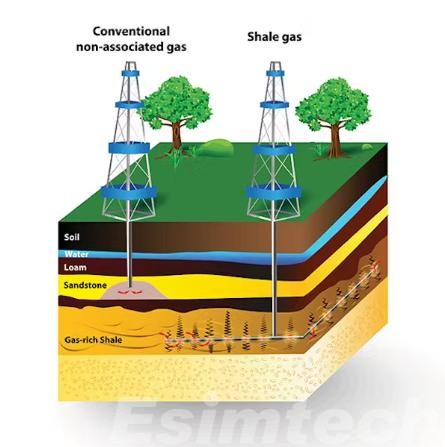

The landscape of energy production has always been subject to changes, and on the frontline of change has been the evolution of shale gas drilling. What was once a truly ground-breaking technique has matured into a sophisticated engineering discipline. Innovations driving modern shale drilling operations are not just boosting efficiency and output but crucially addressing environmental concerns. In this article, we take a closer look at the top innovations that are redefining shale gas extraction in 2025, illustrating an industry that is smarter, cleaner, and more efficient than ever.

Automation in Shale Gas Drilling for Increased Efficiency

Automation is transforming shale gas drilling by streamlining operations and realizing quantifiable efficiency gains. Many of the most advanced automated rigs integrate real-time monitoring, robotic pipe handling, and precision drilling controls to let the operator maintain optimal drilling parameters with very little human intervention.

Key advantages for operators include:

- Significant reduction in NPT: pipe connections, torque adjustments, and other repetitive, high-risk tasks are carried out by automated systems themselves, thus minimizing delays.

- Consistent drilling performance: Sensors and control algorithms continually adjust drilling speed and pressure to maintain wellbore stability; therefore, reducing the risks of setbacks.

- Cost efficiency: Automation can reduce operational costs up to 25% by avoiding manual errors and reducing downtime, so the project is completed more quickly.

In addition, automation enhances safety by limiting human exposure to hazardous drilling environments and provides actionable data for decision-making. Indeed, the adoption of automated solutions is one of the most practical means whereby companies involved in shale drilling and extraction of shale gas may remain competitive, improve productivity, and reduce costs in 2025.

Advanced Wellbore Techniques in Shale Drilling

Wellbore stability and precision are critical in shale drilling in achieving efficient and cost-effective operations. Recent innovations in wellbore design and construction are allowing operators to drill longer horizontal sections, through increasingly complex geological formations, and maximize gas recovery.

Key developments include:

- Optimized well trajectory planning: Advanced software enables the modeling of the most efficient drilling path by engineers, thereby reducing the chances of collision or deviation that can lead to costly delays.

- High-performance drill bits and casing systems: New materials and designs are increasing durability and penetration rates. This enables operators to drill faster without sacrificing wellbore integrity.

- Improved Cementing and Stabilization: By preventing well collapse and reducing the likelihood of fluid migration through improved cement formulations and placement techniques, safer and more reliable extraction of shale gas is ensured.

For companies involved in shale drilling and the extraction of shale gas, these advanced techniques in wellbore directly affect operational efficiency, downtime reduction, and improvement in total project economics. Operators will be able to realize more predictable drilling results, higher gas yields, and a far stronger return on investment with the adoption of such innovations.

AI and Data Analytics in Shale Gas Drilling Operations

Artificial intelligence and data analytics are transforming shale gas drilling operations, converting vast amounts of drilling data into actionable insights. From sensor readings to historical well performance, and drilling simulators, AI tools enable operators to make quicker, better decisions aimed at optimizing not only efficiency but also safety.

Key benefits include:

- Predictive maintenance: Machine learning algorithms detect early signs of equipment wear or failure, thus enabling preventive action that minimizes downtime and maintenance costs

- Optimized drilling parameters: AI continuously analyzes drilling conditions, like torque, rate of penetration, and formation pressure, to recommend adjustments that improve drilling speed and wellbore stability.

- Improved decision-making: Real-time analytics give operators a clear, panoramic view of operations, allowing them to take proactive responses when unexpected geological challenges or operational anomalies arise.

For companies involved in shale drilling and shale gas extraction, the integration of AI and data analytics will directly equate to cost savings, improved operational reliability, and overall higher productivity. These technologies give the operators a competitive advantage and afford them the ability to make informed, data-driven decisions in ever-increasingly complicated drilling environments.

Environmentally Friendly Shale Gas Extraction Practices

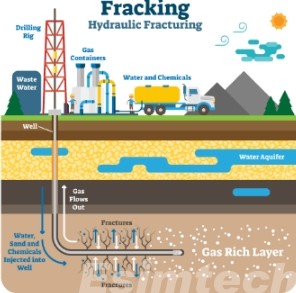

Operating sustainability has become the prime focus of shale gas extraction, with regulators, investors, and communities calling for environmentally responsible operations. New practices have allowed companies to reduce ecological impact without losing operational efficiency.

Key strategies include:

- Water Recycling and Treatment: Advanced systems capture and treat flowback and produced water, reducing freshwater consumption and minimizing wastewater discharge.

- Methane Emission Control: Leak detection technologies and proactive mitigation measures against greenhouse gas emissions contribute to compliance with environmental regulations.

- Optimized hydraulic fracturing: Involves precision fracturing methodologies that more effectively target the gas-rich zone, reducing surface disturbance and minimizing chemical requirements.

These practices guarantee eco-compliance, but also contribute to corporate reputation and investor confidence. For those companies engaged in shale drilling and shale gas extraction, these innovative technologies represent an expression of sustainability while maintaining productivity and cost-effectiveness-two most important determinants of long-term operational success.

High-Performance Drilling Equipment for Shale Gas Extraction

Modern shale gas extraction requires high-performance equipment to enable operators to perform drilling more efficiently, safely, and economically. Advancements in rig design, drill motors, and bit technologies are aiding companies in addressing complicated formations while achieving higher productivity.

Key innovations include:

- Modular and automated rigs: Designs that are flexible enable quicker mobilization of the rig and adaptation to various drilling conditions. Automation reduces manual work and errors in operations.

- Advanced drill bits and motors: High-torque, wear-resistant drill bits enable faster penetration rates and longer horizontal sections, thereby improving well productivity.

- Integrated monitoring systems: Allow real-time feedback from sensors and control systems to maintain wellbore stability and optimize drilling parameters for maximum personnel safety.

It means that investment in high-performance equipment by companies for shale drilling and the extraction of shale gas will directly lead to lower operational costs, faster completion of projects, and enhanced reliability. This will enable operators to optimize the recovery of gas, sustain repeat performance in wells, and realize a better return on their investments.

Conclusion: The Core Values

In 2025, the most successful shale gas drilling operations incorporate innovation with results that can be accurately measured. Automation, advanced wellbore techniques, AI-driven analytics, environmentally responsible extraction practices, and high-performance equipment are more than simple technological trends but rather are core drivers of efficiency, safety, and profitability in shale drilling and shale gas extraction.

Why these innovations matter:

- The automated systems and high-performance equipment bring down the levels of downtime, while increasing the speed of completion.

- Advanced wellbore techniques and real-time monitoring minimize operational risks.

- Environmentally conscious practices ensure compliance and enhance corporate reputation.

- Optimized operations and predictive analytics that improve ROI and ensure long-term profitability.

Core values are the key to resource recovery maximization, cost reduction, and further sustainable growth. This strategic focus will position operators for success in an increasingly complex and demanding energy market.