Top Drive Drilling in High-temperature and High-pressure Environments: Challenges and Innovative Solutions

Top drive drilling plays a crucial role in the field of oil extraction, especially in high-temperature and high-pressure environments. With its unique design advantages, top drive drilling can provide higher drilling efficiency and better safety assurance.

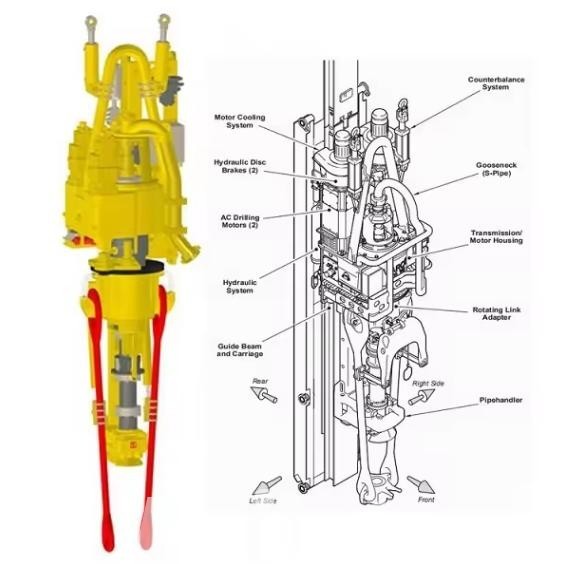

The Working Principle of Top Drive Drilling

Top drive drilling is a method of drilling operations achieved by rotating the drill pipe through a top drive system installed on the wellhead. This technology can complete various drilling operations such as root connection, up and down coupling, and reverse drilling, significantly improving the efficiency of drilling operations.

The top drive drilling system mainly consists of key components such as the top drive, high-pressure pump, and control system. The top drive is responsible for providing rotation and lifting power for the drill pipe, while the high-pressure pump is responsible for injecting drilling fluid into the drill pipe to form a circulating flow, achieving cooling and cleaning effects. The control system monitors and controls the operation of the entire system to ensure the safety and stability of the drilling process.

Challenges of Top Drive Drilling in High-temperature and High-pressure Environments

1. Equipment Heat Resistance

High temperatures may cause thermal expansion of drilling equipment materials, affecting the normal operation and accuracy of the drilling equipment.

2. Power Transmission Efficiency

High temperatures can affect the viscosity of hydraulic oil, which in turn affects transmission efficiency and drilling power.

3. Downhole Tool lifespan

High temperature environments may accelerate the wear of drill bits and other downhole tools, shortening their lifespan.

4. Data Accuracy

High temperatures may affect the accuracy of measuring instruments and increase the risk of drilling operations.

Innovative Techniques for Top Drive Drilling in High-temperature and High-pressure Environments

The new techniques for top drive drilling in high-temperature and high-pressure environments mainly include innovations in drilling fluid technology, wellbore stabilization technology, drill bits and tools technology, measurement while drilling, etc. These technological innovations aim to improve drilling efficiency, ensure drilling safety, adapt to extreme environmental conditions, and achieve automation and intelligence in the drilling process.

1. Drilling Fluid Technology

Drilling fluid technology is crucial in the drilling process, especially in high-temperature and high-pressure environments. The latest drilling fluid technology focuses on improving the thermal stability, rheological properties, filtration control, lubrication, salt resistance, and environmental adaptability of drilling fluids. Research has found that additives with specific structures, such as sulfonates, methyl, phenyl, furan, lactam, and pyrrolidine functional groups, can enhance the thermal stability of drilling fluids. In addition, new materials such as ionic liquids, cationic surfactants, functionalized nanoparticles, and functionalized biopolymers have also been used to improve the performance of drilling fluids. In practical applications, such as the Western South China Sea oil drilling project and the US Gulf of Mexico deepwater oil drilling project, these technologies have been used to effectively address the challenges brought by high-temperature and high-pressure environments.

2. Wellbore Stabilization Technology

The wellbore stabilization technology is crucial in high-temperature and high-pressure environments, as changes in the mechanical and chemical properties of formation rocks may lead to wellbore instability. The latest wellbore stabilization techniques include reasonable selection of drilling fluid types and performance, optimization of wellbore structure, and use of weighting materials. The development of new wellbore stability methods such as microseismic monitoring technology and dynamic monitoring of formation pressure has improved the reliability and efficiency of wellbore stability.

3. Innovations in Drill Bit and Drilling String

The advancement of drill bits and drilling string is crucial for high-temperature and high-pressure drilling. The application of new materials, optimization of structural design, improvement of wear resistance and impact resistance, and other technological innovations have enabled drill bits and tools to work efficiently in harsh environments. The application of advanced drilling techniques such as high-speed turbine drilling and impact drilling has greatly improved drilling efficiency and accuracy.

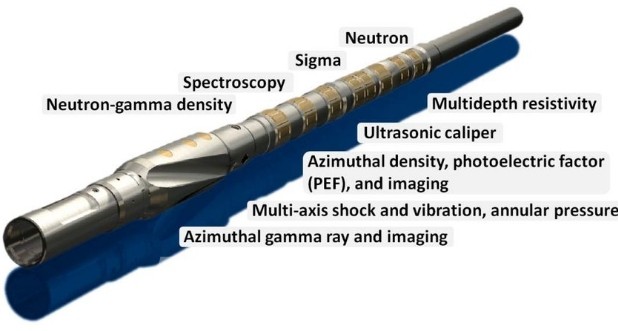

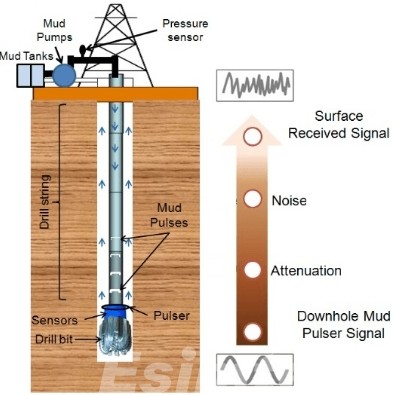

4. Measurement While Drilling Technique

Measurement While Drilling monitors and adjusts real-time information such as drill bit position, direction, depth, etc. during the drilling process, achieving precise control and preventing accidents. In high-temperature and high-pressure environments, these technologies need to face higher challenges, such as high-temperature resistance performance of drilling equipment, signal transmission stability, etc. The application of high-precision drilling measurement systems such as gyroscopes and electromagnetic wave transmission technology has improved the accuracy and reliability of Measurement While Drilling technique.

5. Intelligent Technology

Intelligent technologies, including artificial intelligence, big data, cloud computing, etc., are being applied to the automation and intelligent decision-making of drilling processes. These technologies can improve drilling efficiency and safety, reducing manual labor intensity, analyzing and predicting drilling data, thereby optimizing drilling parameters and preventing potential risks in advance.

Simulation Technology Used for Top Drive Drilling in High-temperature and High-pressure Environments

The application of top drive drilling simulation technology in high temperature and high pressure environments provides a safe and efficient drilling operation solution for the oil extraction field through highly reduced simulation training, helping workers to train and practice drilling operations without being exposed to hazardous environments. This simulation technology typically involves the integration of complex mechanical, electrical, and hydraulic systems, as well as a high degree of restoration of drilling operation processes.

Top drive drilling simulation system constructs accurate mechanical models through computer simulation software to simulate various physical phenomena in drilling operations, such as the rotation and lifting of drill pipes, and the circulation of mud. In addition, it can also simulate emergency response operations in emergency situations, such as the use of blowout preventers, mud handling, etc.

Through top drive drilling simulation training, personnel can conduct practical drilling operations without being restricted by high temperature and pressure environments. This not only helps to improve work efficiency, but also significantly reduces the risks that may occur in actual operations.

Conclusion

The application of top drive drilling in high-temperature and high-pressure environments involves many technical fields, including drilling rock stability control, drilling fluid technology, wellbore stability technology, etc. Faced with various challenges, Technical innovations will help promote the continuous development of top drive drilling in high-temperature and high-pressure environments .