Unveiling CO2 Enhanced Oil Recovery: An Innovative Sustainable Energy Solution

CO2 Enhanced Oil Recovery (EOR) stands as a pioneering technique in the realm of oil extraction, offering the dual benefit of increasing oil production while concurrently mitigating carbon emissions. This article explores the processes, benefits, challenges, and solutions of CO2 Enhanced Oil Recovery and how simulation technology is used in optimizing and enhancing the effectiveness of CO2 EOR processes, shedding light on its role in the transition towards a more sustainable energy future.

Understanding CO2 Enhanced Oil Recovery

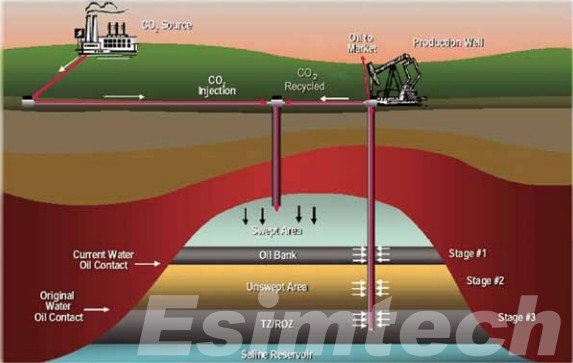

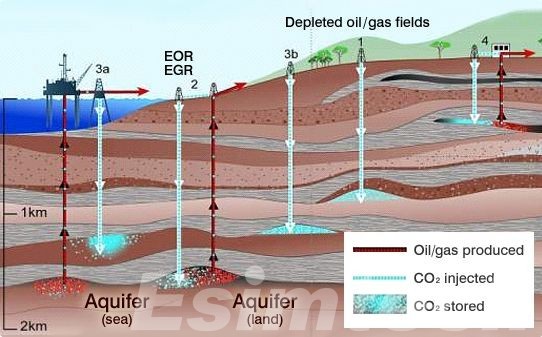

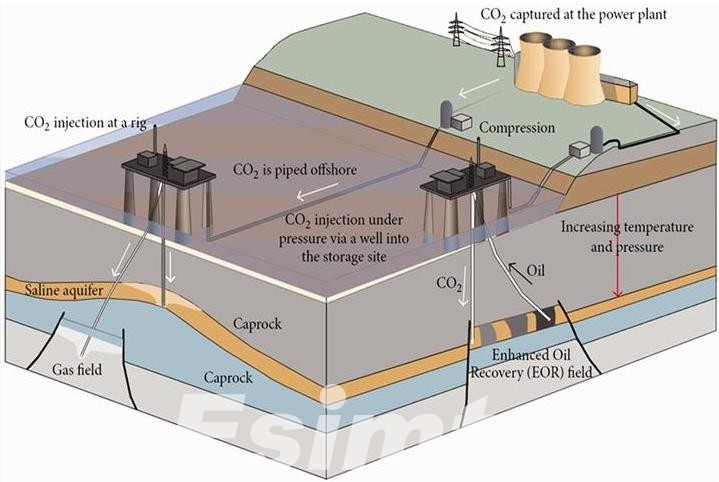

CO2 EOR is a technique designed to maximize the extraction of oil from mature reservoirs by injecting carbon dioxide (CO2) into underground formations. Unlike conventional oil extraction methods that rely solely on natural pressure or secondary recovery techniques such as water flooding, CO2 Enhanced Oil Recovery offers a more proactive approach to reservoir management.

Key Processes Involved in CO2 Enhanced Oil Recovery

CO2 Enhanced Oil Recovery (EOR) involves several processes that work together to increase the amount of oil that can be extracted from underground reservoirs. These processes leverage the properties of carbon dioxide (CO2) to improve oil mobility and displacement within the reservoir.

1. CO2 Capture and Sourcing

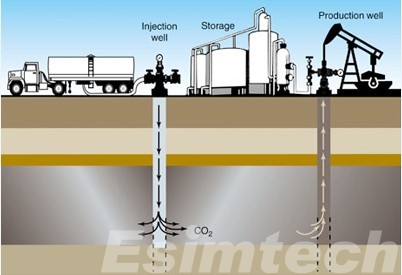

The first step in CO2 EOR is to obtain a source of CO2. This can be sourced from various industrial processes such as power plants, refineries, or natural underground reservoirs. The CO2 is captured, purified, and compressed to the desired pressure for injection into the reservoir.

2. Injection Well Preparation

Once the CO2 is obtained, injection wells are drilled into the oil reservoir. These wells are strategically located to ensure the efficient distribution of CO2 within the reservoir. Well preparation may involve perforating the casing and installing downhole equipment such as tubing, packers, and valves.

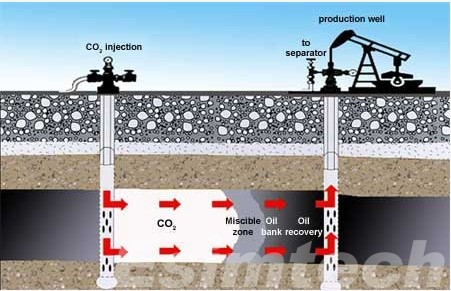

3. CO2 Injection

CO2 is injected into the reservoir through the injection wells at high pressure. The injected CO2 displaces the oil and pushes it towards production wells. This process reduces the viscosity of the oil, improves its mobility, and increases the sweep efficiency within the reservoir.

4. Fluid Flow and Displacement

As CO2 interacts with the oil in the reservoir, several fluid flow mechanisms come into play:

- Viscosity Reduction: CO2 acts as a solvent, reducing the viscosity of the oil and making it easier to flow through the reservoir rock.

- Oil Swelling: CO2 causes the oil to swell, increasing its volume and pushing it towards production wells.

- Multiphase Flow: CO2 and oil flow through the reservoir as a multiphase mixture, displacing trapped oil and increasing recovery efficiency.

5. Reservoir Response

The injected CO2 interacts with the reservoir rock and fluids, leading to changes in reservoir pressure, temperature, and fluid saturation. Reservoir response to CO2 injection is monitored using various techniques such as pressure gauges, temperature sensors, and production data analysis.

6. Production Well Operation

Oil and CO2 are produced from the reservoir through production wells. As CO2 displaces oil towards the production wells, the mixture of oil and CO2 is brought to the surface, where it is separated and processed. The separated oil is then transported to refineries for further processing.

7. Monitoring and Optimization

Throughout the CO2 Enhanced Oil Recovery process, reservoir performance is monitored continuously to optimize injection rates, well placement, and operating parameters. Advanced reservoir simulation models are used to predict reservoir behavior and optimize CO2 injection strategies.

8. Project Evaluation and Closure

Once the CO2 EOR project is completed, the reservoir is evaluated to assess the effectiveness of the CO2 injection and the overall increase in oil recovery. The project is then decommissioned, and the site is restored to its original condition.

The Benefits of CO2 Enhanced Oil Recovery

1. Increased Oil Recovery

One of the primary advantages of CO2 EOR is its ability to unlock additional oil reserves that were previously deemed unrecoverable using conventional extraction methods. This enhanced recovery factor can significantly extend the productive life of mature oil fields.

2. Carbon Emissions Reduction

CO2 EOR offers a unique opportunity to repurpose carbon dioxide emissions from industrial sources such as power plants and refineries. By capturing and injecting CO2 underground, the process effectively sequesters carbon, mitigating its release into the atmosphere and contributing to climate change mitigation efforts.

3. Economic Viability

Beyond its environmental benefits, CO2 EOR can also be economically viable. The increased oil production resulting from CO2 injection can generate substantial revenue, offsetting the costs associated with CO2 capture and injection infrastructure.

4. Utilization of Existing Infrastructure

In many cases, CO2 Enhanced Oil Recovery can leverage existing oil field infrastructure, including wells, pipelines, and processing facilities. This minimizes the need for significant capital investment and streamlines the implementation process.

Challenges and Solutions in CO2 Enhanced Oil Recovery

CO2 Enhanced Oil Recovery holds immense potential for increasing oil production while reducing carbon emissions. However, several challenges must be overcome to realize its full benefits.

1. CO2 Availability and Sourcing

Challenge

Ensuring a reliable and cost-effective supply of CO2 is essential for successful CO2 EOR implementation. Limited availability and high costs associated with sourcing CO2 can hinder project viability.

Solution

- Diversified Sourcing: Utilize multiple sources of CO2, including natural reservoirs, industrial emissions, and carbon capture from power plants and other industrial facilities.

- Infrastructure Investment: Invest in CO2 capture, purification, and transportation infrastructure, including pipelines and compression facilities, to enable cost-effective delivery of CO2 to oil fields.

- Policy Support: Implement policies and incentives, such as carbon pricing or tax credits, to incentivize CO2 capture and utilization and make CO2 EOR economically viable for industrial facilities.

2. Reservoir Heterogeneity and Complexity

Challenge

Reservoir heterogeneity, including variations in porosity, permeability, and fluid properties, poses challenges for efficient CO2 distribution and oil displacement.

Solution

- Advanced Reservoir Characterization: Conduct detailed geologic and reservoir characterization studies to understand reservoir heterogeneity and optimize CO2 injection strategies.

- Adaptive Management: Implement adaptive reservoir management strategies that adjust CO2 injection rates and well placement based on real-time monitoring data and reservoir performance feedback.

3. Environmental and Regulatory Compliance

Challenge

Environmental and regulatory requirements related to CO2 storage, injection, and monitoring must be addressed to ensure project compliance and mitigate environmental risks.

Solution

- Comprehensive Risk Assessment: Conduct thorough environmental impact assessments and risk analyses to identify potential risks and develop mitigation measures.

- Stakeholder Engagement: Engage with stakeholders, including local communities, regulatory agencies, and environmental organizations, to address concerns, build trust, and foster transparency.

- Regulatory Alignment: Ensure compliance with regulatory requirements for CO2 storage and injection, including permits, monitoring, reporting, and remediation plans, to mitigate environmental risks and ensure project success.

4. Technological Innovation and Optimization

Challenge

Continuous technological innovation and optimization are necessary to improve CO2 EOR efficiency, reduce costs, and maximize oil recovery.

Solution

- Research and Development: Invest in research and development of innovative CO2 EOR technologies, including advanced reservoir characterization techniques, enhanced fluid modeling approaches, and novel injection and monitoring technologies.

- Pilot Projects: Conduct pilot projects and field trials to test and validate new technologies under real-world operating conditions, providing valuable insights and lessons learned for future project deployment.

- Collaboration and Knowledge Sharing: Foster collaboration and knowledge sharing among industry stakeholders, research institutions, and government agencies to accelerate technology innovation and adoption in CO2 EOR.

5. Economic Viability and Cost Management

Challenge

CO2 EOR projects require significant upfront investment and ongoing operational costs, making economic viability a key consideration.

Solution

- Cost Optimization: Implement cost optimization strategies, such as minimizing drilling and injection costs, optimizing well placement and spacing, and maximizing oil recovery efficiency.

- Revenue Enhancement: Explore revenue enhancement opportunities, such as carbon credits, enhanced oil prices, and government incentives, to offset project costs and improve financial returns.

- Risk Management: Conduct thorough risk assessments and sensitivity analyses to identify and mitigate potential financial risks, including oil price volatility, regulatory uncertainty, and technology deployment risks.

Commonly Used Simulation Technologies in CO2 Enhanced Oil Recovery

1. Reservoir Simulation

Reservoir simulation involves creating numerical models of underground reservoirs to simulate fluid flow, heat transfer, and chemical reactions within the reservoir. In CO2 EOR, reservoir simulation allows engineers to:

- Model Fluid Flow: Simulate the movement of CO2 and oil within the reservoir, accounting for factors such as reservoir heterogeneity, fluid properties, and injection rates.

- Predict Reservoir Performance: Forecast the impact of CO2 injection on reservoir pressure, temperature, fluid saturation, and oil displacement over time.

- Optimize Injection Strategies: Evaluate different injection scenarios, such as injection rates, well placement, and timing, to optimize oil recovery and minimize operational costs.

1. Fluid Behavior Modeling

Fluid behavior modeling focuses on simulating the interaction between CO2, oil, water, and reservoir rock under various temperature and pressure conditions.

- Equation of State (EOS) Models: Represent the thermodynamic properties of CO2-oil-water mixtures, allowing engineers to predict phase behavior, fluid densities, and interfacial tensions.

- Multiphase Flow Simulation: Model the simultaneous flow of CO2, oil, and water within the reservoir, accounting for phase transitions, fluid displacement, and capillary effects.

- Chemical Reaction Kinetics: Simulate chemical reactions between CO2 and reservoir fluids, such as oil swelling, dissolution, and mineral precipitation, to predict their impact on oil recovery and reservoir performance.

2. Geologic Modeling

Geologic modeling involves creating 3D representations of underground reservoirs based on geological data, well logging simulation, and seismic surveys. In CO2 EOR, geologic modeling allows engineers to:

- Characterize Reservoir Heterogeneity: Capture variations in reservoir properties, such as porosity, permeability, and rock lithology, to accurately represent reservoir behavior and CO2 distribution.

- Identify Injection Targets: Identify suitable injection zones and reservoir compartments with the highest potential for CO2 storage and oil displacement.

- Integrate Geologic and Engineering Data: Combine geologic models with reservoir simulation results to refine reservoir characterization and optimize CO2 injection strategies.

3. Uncertainty and Sensitivity Analysis

Uncertainty and sensitivity analysis techniques are used to quantify the impact of uncertain parameters and assumptions on CO2 EOR performance predictions.

- Monte Carlo Simulation: Generate multiple reservoir simulation runs with randomly sampled input parameters to assess the range of potential outcomes and quantify uncertainty in oil recovery predictions.

- Sensitivity Analysis: Identify key parameters and variables that have the most significant impact on CO2 EOR performance, allowing engineers to focus efforts on optimizing critical factors and reducing uncertainty.

4. Integrated Asset Modeling

Integrated asset modeling involves integrating reservoir, surface facilities, and economic models to simulate the entire CO2 EOR process from injection to production. This enables engineers to:

- Optimize Field Development Plans: Evaluate the economic viability of CO2 EOR projects by considering factors such as capital investment, operating costs, oil prices, and project economics.

- Assess CO2 Capture and Injection Scenarios: Analyze different CO2 capture and injection scenarios, including CO2 source selection, transportation logistics, and injection well placement, to identify optimal project configurations and maximize CO2 utilization.

Conclusion

CO2 Enhanced Oil Recovery represents a convergence of technological innovation, environmental stewardship, and economic pragmatism. As the global energy landscape continues to evolve, CO2 EOR stands as a tangible example of how the oil and gas industry can adapt and contribute to the transition towards a more sustainable energy future.

Oil and Gas Simulation technology plays a critical role in optimizing CO2 Enhanced Oil Recovery processes by providing insights into reservoir behavior, fluid dynamics, and project economics. By leveraging advanced simulation techniques, engineers can design and implement CO2 EOR projects that maximize oil recovery, minimize environmental impact.