What are the Different Types of BOPs in Drilling

In the world of oil and gas drilling, safety is paramount. One critical component that ensures the safety of drilling operations is the Blowout Preventer (BOP). BOPs play a pivotal role in preventing uncontrolled releases of hydrocarbons from the wellbore, which can lead to catastrophic blowouts. These devices are engineered to shut down the well in emergencies and are a vital part of the drilling equipment.

Types of Bops

Annular BOP

The Annular Blowout Preventer, often referred to as the “annular,” is a flexible, donut-shaped device that can seal around various sizes of pipe and maintain wellbore integrity. It is usually positioned on top of the BOP stack. Annular BOPs are versatile and can accommodate a wide range of pipe sizes, making them suitable for various drilling operations.

Function

- Annular BOPs create a seal by closing around the drill pipe, casing, or other tubular components, preventing the escape of pressurized fluids.

- They are used to control the well during drilling, tripping, and various intervention operations.

Design

- Annular BOPs consist of a reinforced rubber element surrounded by a steel structure.

- Hydraulic pressure is applied to squeeze the rubber element, creating a seal.

Applications

- Annular BOPs are commonly used as a secondary BOP on the drilling rig.

- They are crucial during well control operations to maintain pressure control.

Ram BOP

Ram Blowout Preventers are robust, hydraulically-operated devices designed to seal the wellbore by using pairs of opposing steel rams. These rams can close around the pipe, providing a secure and effective seal.

Function

- Ram BOPs use two sets of opposing rams: annular and pipe rams.

- Annular rams are used for sealing around irregular shapes, such as drill collars or tool joints.

- Pipe rams are used for sealing around the drill pipe or casing, making them a more specific choice.

Design

- Ram BOPs are built with high-strength materials to withstand extreme pressures and temperatures.

- Hydraulic systems control the operation of the rams, allowing for quick responses in emergencies.

Applications

- Ram BOPs are usually positioned below the annular BOP in the BOP stack.

- They are crucial for shutting off the wellbore in the event of a kick or blowout.

Types of Ram Bops

Ram BOPs come in two main types: blind rams and pipe rams. Blind rams provide a complete seal when no tubulars are present, while pipe rams are designed to seal around the drill pipe or casing.

1. Blind Rams

Blind rams are designed to close off the wellbore completely. They have no openings and are used when there is no pipe in the wellbore, such as during drilling or maintenance operations.

2. Shear Rams

Shear rams are equipped with sharp blades that can cut through the drill pipe or casing. They are used as a last resort when other BOPs fail to control a blowout. Shear rams sever the pipe, allowing the well to be sealed.

Blind Shear Ram BOP

Blind Shear Ram BOPs are a specialized type of ram BOP with a unique purpose: to sever the drill pipe or casing if necessary. This extreme measure is taken when conventional sealing methods fail to control a blowout.

Function

- Blind shear ram BOPs have cutting blades that shear through the drill pipe or casing to isolate the wellbore.

- They are a last-resort safety measure to prevent uncontrolled blowouts.

Design

- These BOPs are engineered with robust shearing mechanisms capable of cutting through thick steel.

Applications

- Blind shear ram BOPs are usually installed as the last ram in the BOP stack.

- They are rarely used but are a critical component for extreme well control situations.

Hinged Gate BOP

Hinged Gate BOPs are typically used in workover and well intervention operations rather than drilling. They provide a more accessible means of well control for maintenance and repair activities.

Function

- Hinged gate BOPs use a pair of hinged gates that swing open and close around the pipe.

- They offer a quick and reliable way to secure the wellbore during intervention operations.

Design

- Hinged gate BOPs have a simple, compact design.

- They are easy to install and operate, making them ideal for well servicing.

Applications

- Hinged gate BOPs are commonly used during workover operations to maintain control over the well during servicing.

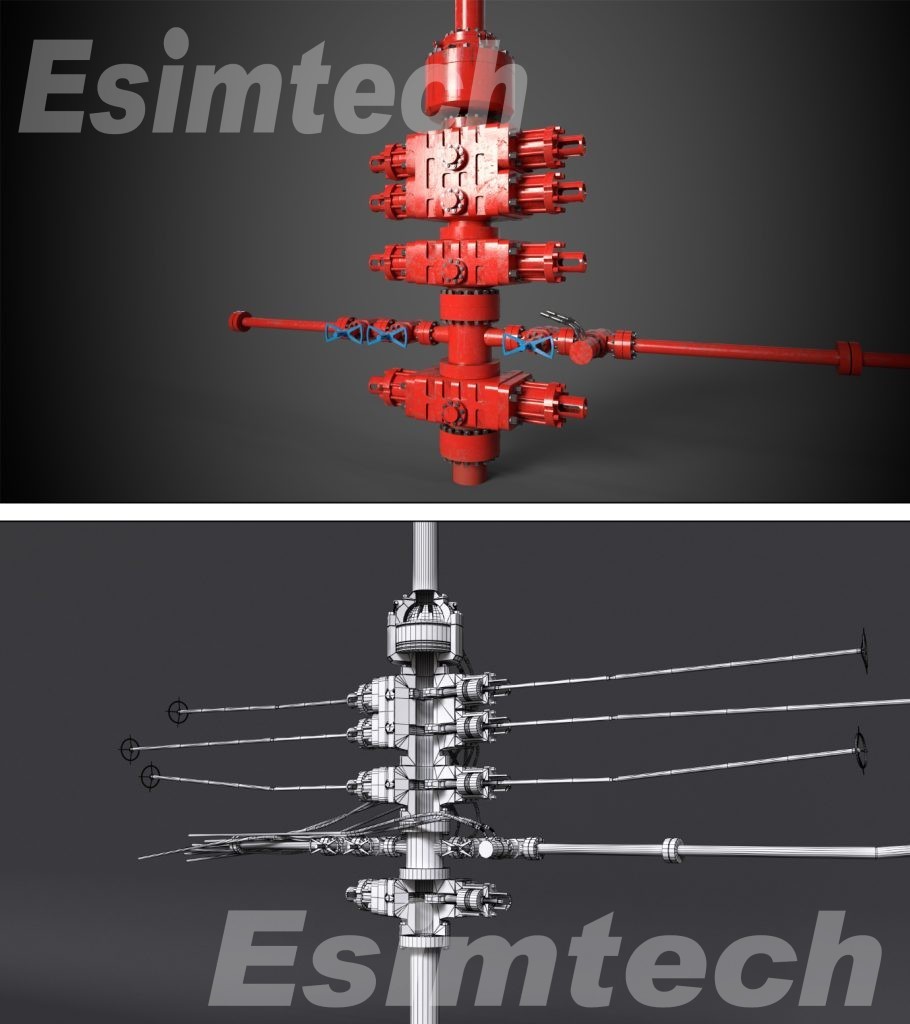

Subsea BOP

Subsea Blowout Preventers are specially designed BOPs for offshore drilling operations. They are positioned on the seabed and are crucial for preventing blowouts in underwater wells.

Function

- Subsea BOPs perform the same functions as surface BOPs but are adapted for subsea conditions.

- They maintain wellbore integrity and prevent hydrocarbon release into the ocean.

Design

- Subsea BOPs are built to withstand high pressures, corrosive seawater, and extreme depths.

- They are remotely operated and connected to the surface by hydraulic control systems.

Applications

- Subsea BOPs are exclusively used in offshore drilling and are a critical component of deepwater drilling rigs.

Importance of BOPs in Drilling

The significance of BOPs in drilling cannot be overstated. They are the last line of defense against blowouts and uncontrolled releases of hydrocarbons. Here are some key reasons why BOPs are indispensable in drilling operations:

- Safety

BOPs are designed to protect the lives of rig workers, the environment, and the valuable drilling equipment. They are the primary means of preventing well blowouts, which can lead to catastrophic incidents.

- Environmental Protection

Blowouts can result in the release of oil, gas, and other harmful substances into the environment, causing significant ecological damage. BOPs help prevent these releases, minimizing environmental impact.

- Asset Protection

Drilling rigs and equipment are expensive investments. BOPs safeguard these assets by preventing damage that can occur during a blowout.

- Regulatory Compliance

Many countries have strict regulations governing well control and blowout prevention. Compliance with these regulations is essential to maintain drilling licenses and avoid legal and financial penalties.

- Reputation Management

- A blowout can tarnish a company’s reputation and lead to public outcry. The use of BOPs demonstrates a commitment to safety and responsible drilling practices.

Conclusion

Blowout Preventers are essential safeguards in drilling, ensuring safety and environmental protection. With various types such as annular, ram, blind shear ram, hinged gate, and subsea BOPs, they offer versatility and reliability. These BOPs find applications in drilling, well intervention, and workover operations. Their collective aim is to prevent uncontrolled hydrocarbon releases, maintain wellbore integrity, and safeguard workers and the environment.

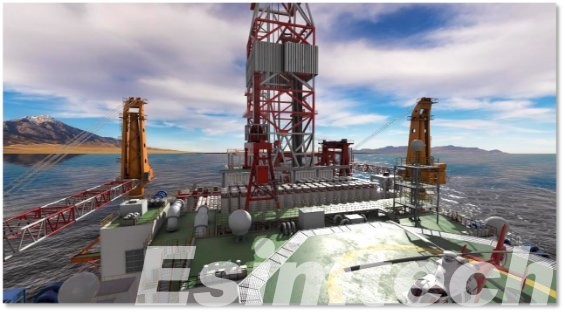

Esimtech specializes in manufacturing oil and gas simulator equipment, including simulation training equipment for Blowout Preventers (BOP). If you require such equipment, please don’t hesitate to get in touch with us.