What are the Different Types of Oil Rig and How to Choose the Right One?

Oil rigs, also known as drilling platforms or offshore platforms, are engineering marvels that play a critical part in the discovery and extraction of lucrative hydrocarbon resources beneath the Earth's surface. These structures are critical to the worldwide oil and gas industry because they allow for the extraction of crude oil and natural gas from the ocean floor. In this article, we will look at the several types of oil rigs, each of which is intended to meet unique offshore locations and drilling requirements, as well as how to select the right oil rig.

What are the Different Types of Oil Rig

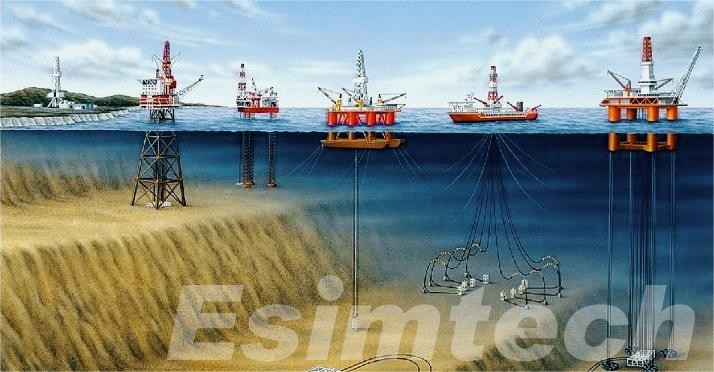

Fixed Platform Rigs

Fixed platform rigs are the most frequent and classic type of oil rig. They are securely moored to the ocean floor, making them robust and secure drilling platforms. Fixed platforms are available in a variety of styles, including:

Jack-up Platforms: These platforms are supported by legs that can be raised or lowered to lift the platform above the water's surface. Jack-up platforms are commonly used in shallow water environments.

Conductor Support Platforms: These platforms are intended for digging deep-water wells. They are comprised of vertical conductors that extend into the seafloor and provide stability and support to the platform.

Caisson Platforms: Caisson platforms are enormous, hollow constructions supported by concrete or other materials. They are primarily employed in shallow to ultra-deepwater depths.

Semi-Submersible Rigs

Semi-submersible rigs are extremely adaptable and can work in both shallow and deep water. They are partially submerged in water and control their draft with ballast systems. Semi-submersibles are well-known for their stability and are frequently employed in inclement weather.

Drillship Rigs

Drillship rigs are ship-like mobile drilling machines. They have drilling equipment and can operate in deepwater and ultra-deepwater environments. Drillships are well-known for their agility and ability to travel fast between drilling locations. They are frequently employed in distant offshore locations for exploratory drilling.

Tension Leg Platform (TLP) Rigs

Tension Leg Platform rigs are used in deepwater drilling projects. They are anchored to the seabed with vertical tethers or tendons that maintain tension, providing stability to the platform. TLPs are suitable for drilling in areas with significant wave motion.

Floating Production Storage and Offloading (FPSO) Rigs

FPSO rigs are unique in that they not only drill for oil but also produce and store it. These vessels are frequently stationed above offshore oil fields and are in charge of processing and storing crude oil until tanker ships can deliver it to shore. Deepwater and isolated offshore sites are common uses for FPSOs.

Compliant Tower Rigs

Compliant tower rigs are used in water depths ranging from 300 to 2,000 feet. They consist of tall, slender towers that are moored to the seabed. These structures are designed to sway with the natural motion of waves and wind, allowing them to absorb and dissipate energy, providing stability for drilling operations.

Subsea Rigs

Subsea rigs are a relatively new innovation in offshore drilling. These methods eliminate the requirement for a standard above-water platform by drilling directly from the seabed. Subsea rigs may be operated and controlled remotely from surface vessels, making them ideal for ultra-deepwater drilling.

Articulated Column Rigs

Drilling in difficult Arctic conditions requires the use of articulated column rigs. They are made up of a single vertical column that is fastened to the seafloor. The platform is designed to pivot in response to ice movements, assuring stability in severe weather.

Mini Rigs

Mini rigs are small and portable drilling devices that are utilized for shallow water or near-shore drilling. These rigs are often moved by truck and may be swiftly constructed, making them appropriate for minor drilling projects.

What are the factors to Consider for Choosing the Right Oil Rig

Selecting the right oil rig requires a comprehensive evaluation of multiple factors.

Determine the Drilling Location

The initial step is to pinpoint the precise site of the drilling. Consider the geographical region, proximity to the beach, and bathymetry (water depth) of the area.

Assess Water Depth

The water depth at the drilling site is a critical factor in selecting the right rig. Different types of rigs are designed for different water depths. Here are some general guidelines:

Shallow Water (Up to 300 feet): Jack-up rigs or fixed platforms are suitable for shallow water drilling.

Intermediate Water (300 to 2,000 feet): Semi-submersible rigs or compliant tower rigs may be appropriate for these depths.

Deepwater (Over 2,000 feet): Drillships, Tension Leg Platform (TLP) rigs, or subsea rigs are typically used in deepwater drilling.

Define Drilling Objectives

Outline the drilling objectives and needs in detail. Are you drilling for exploration, production, or well maintenance? The rig selection will be influenced by the type of drilling and the expected results.

Consider Environmental Conditions

Examine the drilling site's environmental characteristics, such as weather patterns, wave heights, and currents. Some rigs are better adapted to rough seas and harsh weather, while others are better suited to calmer circumstances.

Evaluate Mobilization and Demobilization

Consider how the rig will be transported to and from the drilling site. Some rigs, like drillships, offer greater mobility and faster deployment, while others, like fixed platforms, may require more time and effort to set up.

Budget and Cost Considerations

Evaluate your budget constraints and the overall cost of the drilling project. Different rigs have varying day rates, operational costs, and mobilization expenses. Choose a rig that aligns with your budget while meeting the project requirements.

Regulatory and Permitting Requirements

Ensure compliance with local, national, and international regulations governing offshore drilling. Different regions may have specific requirements for drilling rigs and environmental impact assessments. Obtain the necessary permits and approvals before proceeding.

Safety and Risk Assessment

Conduct a detailed safety and risk evaluation for the rig type of choice. Consider the rig's safety measures, emergency response capability, and track record for safety.

The drilling simulation training system can be of great assistance in assessing safety and risk in oil rigs. It is specifically designed for training individuals on all aspects of safe and effective drilling rig operations, using a display screen, the 3D animation depicting the working conditions, while sound effects imitating a real rig floor create a fully engaging and immersive training environment.

Consult with Experts

Consult with drilling professionals, engineers, and offshore specialists. Work with experienced employees who can offer advice on rig selection based on their understanding of the location and industry best practices.

Flexibility and Adaptability

Choose a setup that is flexible and adaptable to changing conditions. Some rigs, such as semi-submersibles, can operate in a variety of sea depths and environmental circumstances, making them adaptable options.

Maintenance and Availability

Consider the availability of rigs in your selected region as well as the rigs' maintenance schedules. Ensure that the selected rig is in good operational condition and can meet your drilling timeline.

Environmental Impact

Examine the probable environmental impact of drilling activities and choose a rig that will cause the least amount of harm to the local ecosystem. Environmentally friendly features and procedures are frequently incorporated into modern rigs.

Conclusion

Each oil rig is constructed to address the unique challenges of various water depths, weather conditions, and drilling requirements. The location of the oil reservoir, water depth, and environmental issues all influence rig selection. These remarkable structures demonstrate human ingenuity and technological capability in the pursuit of Earth's priceless energy resources beneath the ocean floor.