What are the Risks of Deepwater Drilling for Petroleum

Deepwater drilling for petroleum has revolutionized the oil and gas industry, unlocking vast reservoirs of hydrocarbons previously inaccessible. However, with this technological advancement comes a myriad of challenges and risks, particularly concerning safety and environmental protection. In this article, we delve into the risks associated with deepwater drilling and explore the measures taken to mitigate them.

Challenges of Deepwater Drilling Safety

Deepwater drilling ventures far beyond the continental shelf, pushing the boundaries of human engineering and our ability to operate safely in such a hostile environment. Here's a deeper dive into the specific challenges that compromise safety in deepwater drilling:

1. The Crushing Grip of Pressure: Imagine working under the weight of thousands of meters of water. At these depths, the pressure can reach a staggering 1,500 pounds per square inch (psi) – that's roughly equivalent to the weight of an elephant standing on your thumbnail! This immense pressure can cause several problems:

- Equipment Failure: Drilling equipment, pipes, and even well casings are not immune to the immense pressure. Cracks, leaks, and even complete blowouts can occur if the equipment is not specifically designed and rigorously maintained to withstand these forces.

- Well Control Nightmares: Maintaining control of the wellbore – the hole drilled into the seabed – becomes extremely difficult under high pressure. Even small influxes of oil or gas can quickly escalate due to the immense force pushing them upwards. This can overwhelm well control procedures and lead to a blowout.

2. A Fiery Inferno: The Threat of High Temperatures: As you descend deeper into the ocean, the temperature also rises. At depths relevant to deepwater drilling, temperatures can exceed 200 degrees Celsius (400 degrees Fahrenheit). This extreme heat can have detrimental effects:

- Material Degradation: The high temperatures can weaken drill pipes, casings, and other equipment, making them more susceptible to failure.

- Formation Instability: High temperatures can destabilize the rock formations surrounding the wellbore, leading to cave-ins and further complications during drilling.

- Fire Hazards: Leaks of oil or gas at high temperatures become a significant fire risk. Extinguishing such fires on open water becomes an immense challenge.

3. Remoteness: A Double-Edged Sword: Deepwater drilling often takes place hundreds of kilometers (miles) from shore. This remote location presents a unique set of safety challenges:

- Delayed Response: In the event of an accident, such as a blowout or fire, help can be hours or even days away. This delay can significantly worsen the outcome for both personnel and the environment.

- Limited Resources: Unlike land-based operations, resources and supplies on a drilling rig are limited. This can make it difficult to contain spills, manage well control emergencies, or evacuate personnel in a timely manner.

- Weather Woes: Harsh weather conditions at sea can further complicate rescue and response efforts, adding another layer of risk to deepwater drilling operations.

4. A Delicate Ecosystem at Stake: The deep ocean is a complex and fragile ecosystem. Oil spills pose a devastating threat to marine life, disrupting food chains and causing long-term damage to vital habitats. Deepwater spills are particularly challenging to contain and clean up, as the oil can become dispersed throughout the water column, harming organisms at all depths.

These challenges paint a clear picture of the inherent risks associated with deepwater drilling. Mitigating these risks requires a comprehensive approach that combines technological advancements, stringent safety protocols, and a deep respect for the delicate ocean environment.

Safety Measures and Regulations about Deepwater Drilling

The unforgiving environment of deepwater drilling demands a comprehensive safety net. Here's a closer look at the key safety measures and regulations that govern this industry:

Well Control Procedures

Preventing blowouts is paramount. Here's how well control procedures tackle this challenge:

- Blowout Preventer (BOP) Stacks: These are the first line of defense, essentially a series of valves and rams that can seal the wellbore in various ways. Regulations mandate specific BOP configurations based on well depth, pressure, and other factors. Regular testing and maintenance of BOPs are crucial.

- Wellbore Monitoring: Real-time monitoring of pressure, temperature, and fluid flow within the wellbore is critical. Early detection of anomalies can prevent incidents from escalating. Advanced drilling fluids with specific properties are used to maintain wellbore stability and pressure control.

- Well Casing and Cementing: Multiple layers of steel casing are inserted into the wellbore, progressively narrowing as drilling goes deeper. Cement is then pumped between the casing and the wellbore formation to create a strong, impermeable seal. This prevents fluids from migrating upwards and compromising well control.

- Emergency Shutdown Systems (ESD): These automated systems can shut down drilling operations in the event of a critical issue, such as a sudden pressure surge. Redundant ESDs provide additional safety layers.

Environmental Impact Assessments (EIAs):

Before drilling can commence, a thorough EIA is mandatory. This assessment analyzes the potential environmental risks associated with the project, including:

- Impacts on Marine Life: The EIA evaluates how drilling activities, potential spills, and discharges might affect marine organisms and ecosystems. Mitigation strategies, such as using non-toxic drilling fluids and establishing buffer zones around sensitive habitats, are crucial.

- Habitat Disruption: The EIA assesses potential damage to the seabed and benthic communities (organisms living on the seafloor) caused by drilling activities and equipment placement.

- Oil Spill Modeling: The EIA includes modeling of potential oil spill scenarios, considering factors like currents, weather patterns, and oil characteristics. This helps develop effective spill response plans.

Regulatory Bodies and Standards:

Several international and national regulatory bodies oversee deepwater drilling activities. Here are some key players:

- International Maritime Organization (IMO): Sets international standards for safety and pollution prevention in offshore operations. The IMO's "Marine Environment Protection Committee" (MEPC) regularly updates regulations related to deepwater drilling.

- Bureau of Safety and Environmental Enforcement (BOEMRE) (US): This agency oversees offshore oil and gas exploration and development on the U.S. Outer Continental Shelf (OCS). Following the Deepwater Horizon disaster, BOEMRE implemented stricter regulations on well control, well design, and environmental safeguards.

- International Association of Oil and Gas Producers (OGP): This industry association develops and promotes good practices for safe and environmentally sound exploration and production activities. OGP guidelines provide recommendations for well control, blowout prevention, and environmental management in deepwater drilling.

Compliance and Enforcement

Regular inspections by regulatory bodies ensure that drilling operations adhere to safety standards and environmental regulations. Failure to comply can result in penalties, including fines and suspension of operations.

Continuous Improvement

The quest for enhanced safety is ongoing. Regulatory bodies and industry organizations collaborate to update regulations and best practices based on lessons learned from past incidents and advancements in technology.

In conclusion, safety measures and regulations form a complex but vital web that governs deepwater drilling activities. By adhering to these measures and continuously striving for improvement, the industry can work towards minimizing risks and ensuring the safe and responsible development of these valuable resources.

Technological Advancements for Deepwater Drilling Safety

The relentless pursuit of safety in deepwater drilling has spurred exciting advancements on the technological front. These innovations are not only improving real-time operations but also allowing for better preparation through sophisticated simulations. Here's a deeper dive into some key areas:

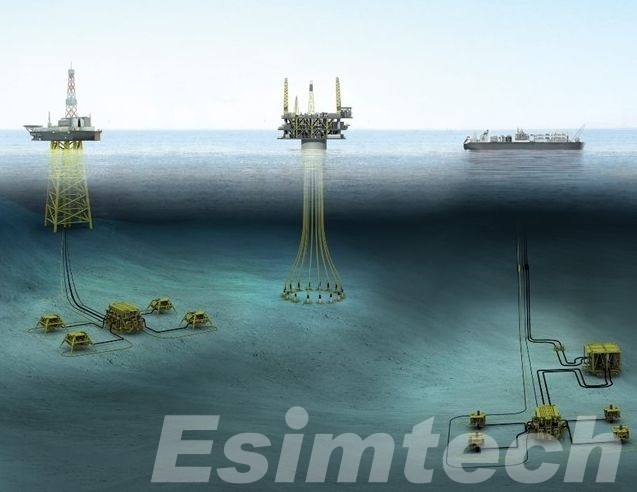

- Subsea Robotics

One of the most significant advancements has been the rise of subsea robotics. These unmanned vehicles, often remotely operated vehicles (ROVs) or autonomous underwater vehicles (AUVs), can perform a variety of critical tasks underwater. They can be deployed for wellhead inspections, maintenance, and even complex valve operations. This not only reduces the need for human divers in risky environments but also allows for more precise and efficient operations. Additionally, some advanced ROVs are equipped with manipulator arms that can handle tools and perform intricate tasks, further minimizing human intervention.

- Real-time Monitoring and Advanced Sensors

Deepwater operations are now heavily reliant on real-time monitoring systems that gather critical data from downhole sensors. These sensors measure a wide range of parameters, including pressure, temperature, flow rates, and wellbore integrity. This data is then transmitted to onshore control centers where engineers can analyze it in real-time. Advanced software helps identify potential issues and predict wellbore behavior, enabling proactive intervention to prevent accidents. Additionally, the development of new sensor technologies with greater sensitivity and reliability allows for even more comprehensive monitoring of well conditions.

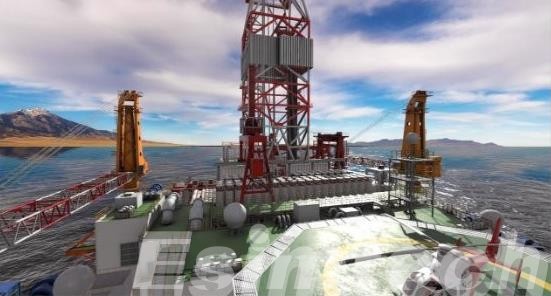

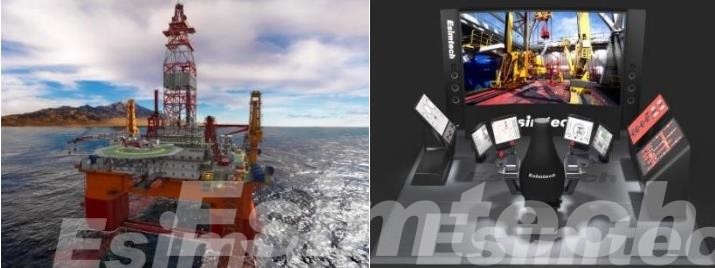

- Simulation Technology

Beyond real-time monitoring, sophisticated simulation technology is playing an increasingly important role in deepwater drilling safety. These simulations create virtual models of drilling operations, encompassing everything from the wellbore and surrounding geology to the drilling equipment and control systems. Engineers can use these simulations to test different scenarios, such as potential blowouts, equipment failures, and environmental conditions. By analyzing how the system reacts in these simulated scenarios, engineers can identify weaknesses, refine procedures, and train personnel to handle emergencies more effectively. Furthermore, simulation technology can be used to optimize drilling plans and procedures, leading to smoother and safer operations.

- Advanced Materials and Design

Material science is also contributing to deepwater drilling safety. Research into stronger, more durable materials for drill pipes, well casings, and other critical components is ongoing. These advancements aim to improve the ability of equipment to withstand the immense pressure and harsh conditions encountered at extreme depths. Additionally, innovative design approaches, such as using lighter yet stronger materials and incorporating redundancy in critical systems, are further enhancing safety margins.

The synergy between these advancements is crucial. Real-time data from downhole sensors, for instance, can be fed into simulation models to create even more realistic training scenarios. Similarly, insights gained from simulations can inform the design and deployment of subsea robots for specific tasks.

Generally, technological advancements are at the forefront of the battle for deepwater drilling safety. By continuously pushing the boundaries of innovation, the industry can strive for a future where deepwater resources are accessed responsibly and sustainably, safeguarding our environment and the brave men and women who work in these demanding environments.

Conclusion

Deepwater drilling presents a complex risk-reward equation. While it offers access to vast oil and gas reserves, the potential consequences of accidents can be catastrophic. A multi-pronged approach, encompassing robust safety measures, stringent regulations, and continuous technological advancements, is essential for ensuring the safe and responsible development of these resources. The future of deepwater drilling hinges on striking a balance between economic gain and environmental and human safety.