What is Cyberchair Drilling Simulator

In the oil and gas business, ensuring the safety and efficiency of drilling operations is critical, as errors can result in major financial losses and environmental damage. Traditionally, training in this sector has consisted of a combination of classroom instruction and hands-on experience. A new technology has evolved to increase training approaches and drill proficiency – the Cyberchair Drilling Simulator. In this article, we will delve into the features, functionalities, and implications of the cyberchair drilling simulator in the oil and gas industry.

Why Choose Cyberchair Drilling Simulator for Training

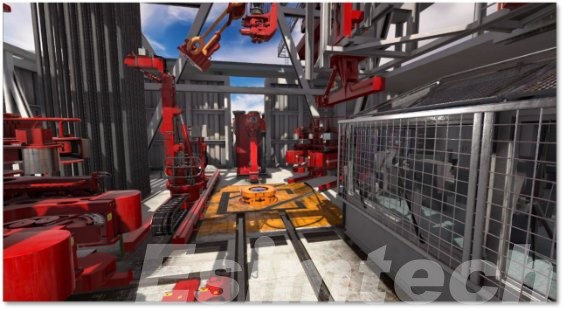

The cyberchair drilling simulator is an innovative virtual reality (VR) training system that provides a realistic and immersive experience of operating drilling equipment. It blends cutting-edge VR technology with sophisticated drilling simulations to reproduce various drilling conditions in a safe environment. The drilling simulator is made up of a physical chair with haptic feedback sensors, a VR headset, and controls that resemble the actual drilling console. Trainees can put on the VR headset, sit in the cyberchair, and be transported onto a virtual drilling rig that simulates the conditions and problems they would face in real-world drilling operations.

Key Features and Functionalities of Cyberchair Drilling Simulator

Realistic Virtual Environment

The simulator generates a virtual environment that is incredibly immersive and lifelike, closely resembling actual drilling locations. Graphics, acoustic effects, and physics-based simulations all work together to give learners a realistic experience. The virtual environment can depict a variety of scenarios, such as offshore or onshore drilling sites, varying weather conditions, and difficult situations.

Interactive Control Panel

The simulator features a control panel that closely resembles that of a drilling rig. Trainees can interact with controls including levers, switches, buttons, and touchscreens in the same way as they would in real-world operations. This hands-on experience aids in the development of muscle memory and familiarity with drilling equipment.

Haptic Feedback Sensors

The cyberchair drilling simulator includes haptic feedback sensors built into the chair. Trainees can feel vibrations, resistance, and other sensations connected with drilling tasks thanks to these sensors, which provide a feeling of touch and physical feedback. This haptic input improves simulation realism and immerses trainees in the training experience.

Diverse Training Scenarios

The simulator includes a variety of training scenarios that span a wide range of drilling techniques, equipment kinds, and operating issues. Students can simulate drilling for various energy sources such as oil, natural gas, or geothermal energy. They may also encounter well blowouts, pressure control concerns, wellbore stability issues, and other unanticipated events. The capacity to simulate many scenarios aids in the development of critical thinking and problem-solving skills in trainees.

Simulation of Drilling Technologies

The cyberchair drilling simulator can replicate the utilization of various drilling methods in the industry. Trainees can practice directional drilling, hydraulic fracturing (fracking), and other specialist procedures. This allows users to learn the subtleties of each technology and acquire hands-on experience with them without the need for real-world equipment.

Real-time Performance Monitoring

The simulator has data collecting and analysis capabilities, allowing for real-time monitoring of learner performance. Trainers can monitor parameters like response time, accuracy, and decision-making abilities. Trainers can use this input to provide quick instruction and identify areas where learners might improve. During the training session, real-time performance monitoring allows students to fine-tune their skills and change their approach.

Data-driven Training Programs

The simulator’s data can be evaluated to create data-driven training programs. Trainers can adapt the training curriculum to address specific areas of weakness or focus on developing certain abilities by recognizing patterns and trends in learner performance. This tailored approach to training increases the simulator’s effectiveness and guarantees that participants receive targeted teaching.

Remote Accessibility

The cyberchair drilling simulator is remotely accessible, allowing trainees to participate in training sessions from multiple places. This function is especially useful for businesses with several training facilities or for learners who are unable to travel to a physical training facility. When physical presence is not possible, remote accessibility increases flexibility and allows for continued training.

Implications of Cyberchair Drilling Simulator for the Oil and Gas Industry

The cyberchair drilling simulator has far-reaching ramifications for the oil and gas industry, influencing operations, training, safety, and efficiency.

Enhancing Training and Skill Development

By offering a realistic and immersive virtual environment for drilling operations, the simulator transforms training approaches. It gives students hands-on training and allows them to practice operating drilling equipment without the risks involved with real-world operations. This immersive training helps learners enhance their skills, knowledge, and decision-making abilities, allowing them to become more competent and effective in their professions.

Improving Safety

The oil and gas business prioritizes safety, and the cyberchair drilling simulator helps to improve safety procedures. The simulator assists trainees in developing the required abilities to respond effectively in real-world circumstances by providing a controlled environment for them to practice handling emergency crises. This decreases the likelihood of drilling mishaps, equipment damage, and injuries.

Reducing Cost

Traditional oil and gas training approaches may require costly on-site drilling activities or sending learners to remote places for practical experience. By eliminating the need for actual equipment and travel fees, the Cyberchair Drilling Simulator provides a cost-effective alternative. Companies can provide training virtually, lowering expenses while maintaining a high-quality learning experience.

Time Efficiency

The simulator can help to hasten the process of skill development. Trainees have unlimited access to the simulator, allowing them to perform drills and acquire experience even during downtime. Furthermore, the simulator can model difficult and uncommon drilling circumstances that would otherwise take years to encounter in real-world operations. This shortens the learning curve and guarantees that trainees are well-prepared for actual drilling operation.

Addressing Skill Shortages

Due to an aging workforce and a dearth of new talent entering the field, the oil and gas industry is confronting a scarcity of skilled drilling employees. The cyberchair drilling simulator addresses this skill gap by providing a training and skill development platform. Companies can efficiently train new employees and upskill existing ones, ensuring a competent workforce that can meet the demands of the industry.

Digital Transformation

The adoption of the cyberchair drilling simulator signifies a step forward in the oil and gas industry’s digital revolution. It exemplifies the industry’s embrace of sophisticated technologies to optimize operations, increase efficiency, and improve safety. The simulator complements the industry’s ongoing efforts to use digital tools and data-driven approaches to improve decision-making and performance optimization.

Data Analytics for Continuous Improvement

The simulator has data collecting and analysis features that provide information about learner performance. The data gathered can be evaluated to uncover patterns, trends, and opportunities for improvement. This data allows for the ongoing improvement of training programs, safety protocols, and operating processes. The data-driven approach aids in the refinement of training procedures, the optimization of drilling processes, and the improvement of overall operational performance.

Summary

The cyberchair drilling simulator is critical to improving oil and gas operations’ safety, efficiency, and sustainability. Its immersive virtual environment, realistic simulations, and interactive controls provide a safe and cost-effective environment for trainees to gain important drilling skills.