What is the Driller’s Method in Well Control

In the high-stakes world of oil and gas drilling, ensuring the safety and stability of a well is paramount. When unexpected conditions arise, such as a kick or a blowout, well control methods, including the Driller’s Method, are employed to regain control over the well. This article provides a comprehensive exploration of the Driller’s Method, delving into its workings, historical context, and the importance of well control training simulations in mastering this essential technique.

Understanding the Basics of The Driller’s Method in Well Control

The Basics of Well Control

Before delving into the specifics of Driller’s Method, it is imperative to grasp the broader context of well control and the paramount importance it holds in the realm of drilling operations.

Well control is a multifaceted discipline that encompasses an array of techniques and strategies aimed at managing and regulating the pressure within the wellbore. This meticulous control of pressure is nothing short of a linchpin in the intricate world of drilling, and it serves a purpose that extends far beyond mere operational convenience—it is a matter of paramount safety and environmental preservation.

drillers methods

The Key Techniques Used for The Driller’s Method in Well Control

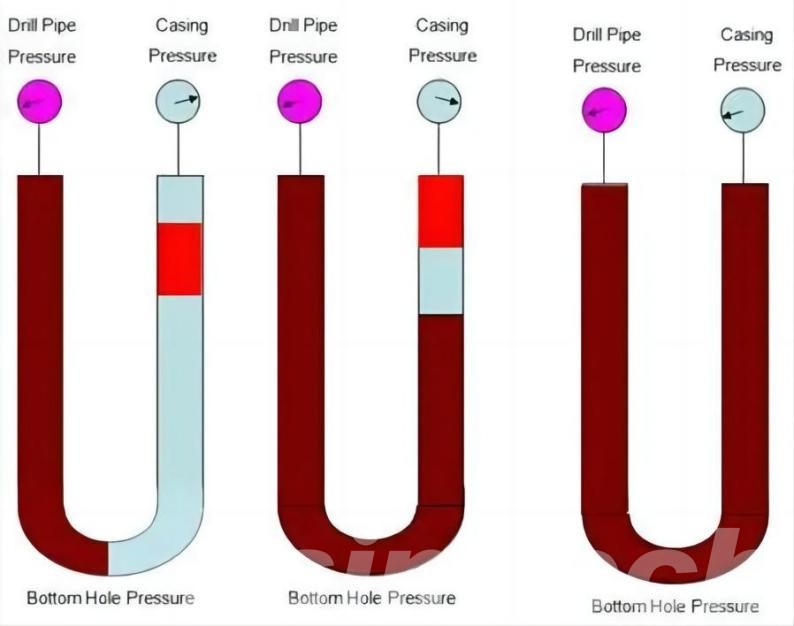

The Driller’s Method is one of several techniques employed to regain control over a well. Its primary objective is to re-establish equilibrium within the wellbore by maintaining a constant bottom hole pressure (BHP). This method requires two complete and separate circulations of drilling fluid within the well.

Recognition and Well Closure

The process commences with the identification of irregular pressure conditions within the well, often caused by an influx such as a gas or oil kick into the wellbore. Upon recognizing such an event, immediate action is taken to shut down the well. This is accomplished by activating the blowout preventer (BOP) and discontinuing drilling operations promptly. This decisive action serves to halt any further influx of fluids or hydrocarbons from the reservoir.

Pressure Assessment

The subsequent step involves a meticulous assessment of the current downhole conditions. This comprehensive evaluation encompasses both the pressure and volume associated with the kick. The accuracy of these measurements is paramount as they form the foundation for the effective implementation of the Driller’s Method.

First Circulation

With the well shut in, the drilling team begins the first circulation. In this phase, heavy drilling mud (usually weighted with barite) is pumped down the drill string and into the well. The goal is to gradually increase the mud density to balance the formation pressure and stop the influx.

Pressure Monitoring

During the first circulation, the pressure at the wellhead is continuously monitored. The drilling team carefully observes the pressure response to the introduction of the heavy mud.

Second Circulation

Once the pressure stabilizes and matches the desired BHP, the first circulation is completed. The drilling team then initiates the second circulation. In this phase, drilling mud is circulated back out of the well, replacing the lighter mud or influx that entered during the kick.

The Importance of the Driller’s Method

The Driller’s Method stands out as a crucial approach to well control due to its focus on maintaining constant BHP. This technique not only helps regain control over a well but also minimizes the risk of wellbore instability, further complications, and potential damage to equipment. By utilizing heavy drilling mud and a systematic approach, drilling professionals can effectively manage unexpected kicks or blowouts and ensure the safety of personnel and the environment.

1.Safety

Safety is paramount in the oil and gas industry. The Driller’s Method prioritizes safety by addressing well control incidents promptly and efficiently. By maintaining constant BHP, it minimizes the risk of uncontrolled flow and potential blowouts, protecting the lives of those working on the rig and safeguarding the environment.

2. Equipment Protection

Well control incidents can exert immense stress on drilling equipment. The Driller’s Method helps protect costly drilling assets by preventing damage caused by excessive pressure and flow rates.

3. Environmental Preservation

In addition to human safety, the method helps prevent environmental disasters by averting uncontrolled oil or gas releases that can lead to pollution and ecological damage.

3. Operational Efficiency

The Driller’s Method allows drilling operations to resume more quickly and efficiently after a well control incident. This minimizes downtime and financial losses, benefiting both operators and investors.

Role of Well Control Training Simulation for Driller’s Method

Well control training is a critical aspect of preparing drilling personnel to effectively implement techniques like the Driller’s Method. Simulation-based training has emerged as a powerful tool in this regard, offering a safe and immersive learning environment for drilling crews.

Simulation in Well Control Training

Simulation technology allows drilling personnel to experience real-life well control scenarios in a controlled and risk-free setting. It replicates the conditions and challenges they might encounter while drilling, including well kicks and blowouts. Here’s how simulation technology plays a pivotal role in well control training:

- Realistic Scenarios: Simulators can recreate well control incidents with remarkable accuracy, providing trainees with a realistic experience of dealing with kicks and blowouts.

- Safe Learning Environment: Drilling personnel can practice well control techniques without the inherent risks associated with live drilling operations. This promotes safer learning and skill development.

- Scenario Customization: Training simulations can be customized to mimic specific drilling rigs, wellbore conditions, and well control challenges, allowing personnel to train for their specific work environment.

- Repeatable Training: Trainees can repeat scenarios as often as needed to build proficiency and confidence in responding to well control incidents.

- Feedback and Assessment: Simulations provide immediate feedback on trainees’ actions and decisions, allowing for continuous improvement and skill development.

- Crew Coordination: Simulated scenarios can also facilitate team training, helping drilling crews learn to work together effectively in high-pressure situations.

Conclusion

In oil and gas drilling, safety and precision are paramount. The Driller’s Method, focusing on constant bottom hole pressure, remains a vital technique. It safeguards lives, assets, and the environment, adapting to evolving drilling challenges. Training simulations are key in preparing future drillers for well control incidents. Together, the Driller’s Method and simulations ensure safe and responsible drilling practices in an ever-changing industry.