How Digital Well Logging Works in Oil Drilling

The exploration of oil and gas in the modern world requires the application of groundbreaking technology, one of which is digital well logging, as it significantly impacts the effectiveness and safety of oil drilling and the overall status of decision-making processes. Operators are better equipped in evaluating subsurface resources and optimizing drilling processes due to the use of complex sensors, instantaneous acquisition of data, cloud-based systems, and other analytic systems which used in digital well logging.

Understanding Digital Well Logging

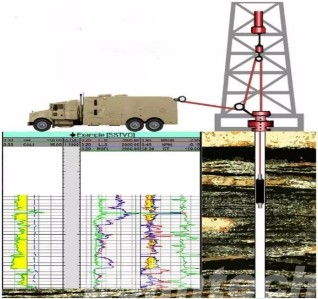

Digital well logging, often referred to as electronic logging, deals with the collection as well as analysis of data pertaining to downhole conditions during oil drilling. In the past, well logging needed manual recording and the withdrawal of data, which subsequently slowed down the processes of making decisions. Digital well logging, with the help of sufficiently advanced devices with sensors, captures and records real-time data pertaining to a series of formation and drilling parameters. This data is then transmitted to the approved operators stationed at the surface.

Key measurements

This chart captures the essential measurements that digital well logging tools collect and the insights they provide for drilling and reservoir evaluation.

| Measurement | Purpose / Information Provided |

| Resistivity & Conductivity | Identifies hydrocarbon-bearing zones and water saturation levels. |

| Porosity & Permeability | Estimates the storage capacity and flow potential of reservoir rocks. |

| Formation Pressure & Temperature | Monitors downhole conditions for safe drilling and reservoir evaluation. |

| Gamma-ray Emission | Indicates shale content, mineral composition, and lithology. |

| Acoustic & Sonic Properties | Determines rock type, detects fractures, and assists in geomechanical modeling. |

| Density & Neutron Measurements | Provides information on rock density, porosity, and fluid content. |

| Nuclear Magnetic Resonance (NMR) | Evaluates pore size distribution and fluid mobility in formations. |

| Caliper / Borehole Geometry | Measures borehole diameter and shape for drilling optimization and tool placement. |

Advantages of Using Digital Well Logging in Oil Drilling

Digital well logging replaced the traditional well logging techniques, which worked via slow data collection. Operators are empowered with tools to help them make decisions instantly, which in turn increases efficiency, safety, and better management of resources.

Real-Time Data Acquisition for Informed Decision-Making

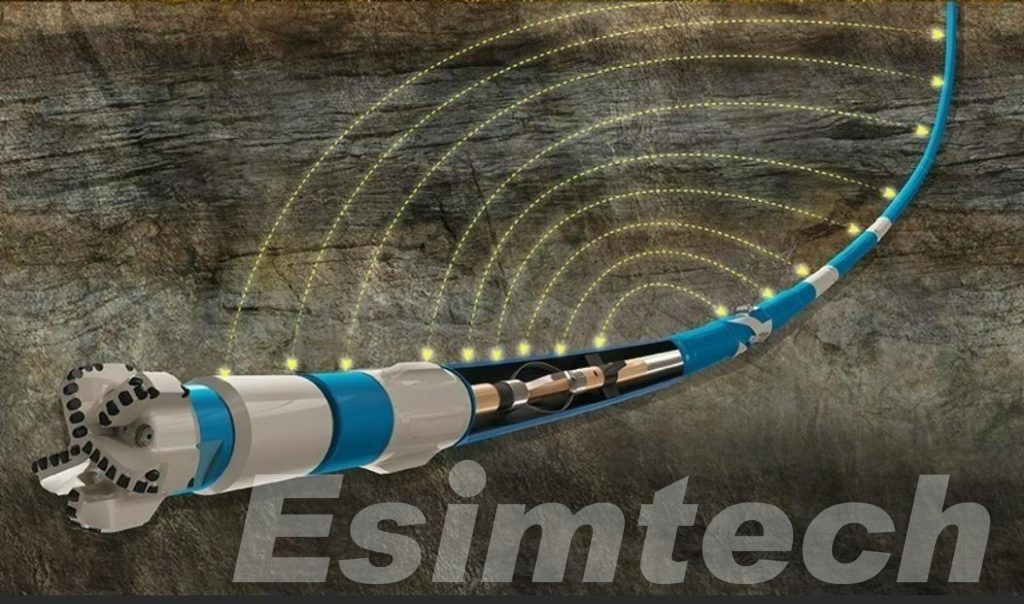

Digitized well logging comes with many advantages, and one such feature is the ability to capture well logging data faster than other techniques. Electronic sensors embedded in downhole tools, and these sensors, can in real time, capture and transmit the resistivity, temperature, and pressure, as well as other attributes, to the surface. As a result, drilling engineers are capable of making faster alterations in the course of drilling, like skipping nonproductive zones, optimizing well trajectories, and reducing operational delays.

Enhanced Accuracy and Resolution

Digital well logging tools enhance the precision of formation evaluation, and their measurements are almost unstructured in their differences. In measurements of geology cross-sections, precision in differences of resistivity, density, and sonic is dominant, making it easy to tell the oil, gas, and water bearing zones. Employing deduction of these measurements, interpretation of uncertainty in the characterizing of the tank is more efficient, as well as in the drilling and production systems.

Improved Operational Safety

Digital well logging is a technique that assuages the concern of safety in oil drilling. Operators can foresee dangerous situations in advance, for example, when they are alerted during real time monitoring of pressure downhole when they are in the middle of drilling. These safety issues range in risk including blowouts, as well as equipment failure. By employing these techniques, personnel are protected, as well as the drilling tools that are costly.

Cost and Resource Efficiency

Digital well logging provide specific formation information that helps bypass irrelevant drilling and prevents costly oversights, thereby saving time and funds that would otherwise be wasted on inefficient drilling and nonproductive zones, as well as excess drilling fluids and equipment. The savings achieved do not just help lower operational costs, but their environmental savings go towards a more economically sustainable form of controlling eco biodiversity.

Versatility Across Exploration and Production Phases

The utility of digital well logging technology in oil and gas operations doesn’t end with a specific stage, as it can be used for exploration to assess formation quality and locate hydrocarbon zones, and to guide well placement, completion and enhanced oil recovery design during appraisal and development. Even in production, digital well logging can be used to facilitate reservoir monitoring, allowing for proper outflow maintenance through proactive changes in reservoir management.

The Working Process of Digital Well Logging in Oil Drilling

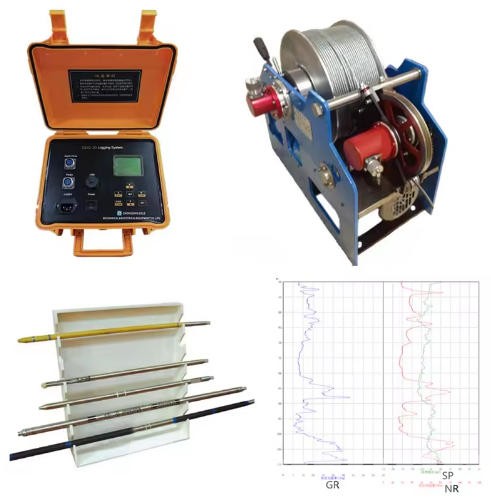

1. Downhole Measurement Tools and Sensors

The first step in digital well logging is done by the use of modern tools placed in teh shaft imbedded with threaded sensors. These sensors quantify the logging formation resistivity and porosity (acoustic and sonic tools) and the formation’s thermal and density ranges (gamma rays). The sensors also determine the abilities of NMR devices. Theses sensors use the formation with the shaft’s utube essence to visualize.

2. Data Transmission to the Surface

The in shaft measurements in this case have to be captured and in real-time processed calculating the remaing surface parameters. For this objective, many pulse sensors are set in teh mud and the shaft sensors which pin point teh shaft elements and the tools use high speed links to connect to the surface computing tools. The use of the earth’s surface electromagnitic fields is a progressive system in which the earth itself acts as a serve to transmit sensors.

3. Surface Data Acquisition and Processing

Digital well logging is done at surface using well logging data acquired at surface by high speed data systems. Specialized software and powerful computers are used to process the sensor readings, forming images and logs from the raw data. Noise and other errors are removed, steps are taken to measure data, and various sensor readings are integrated into models. This stage of processing data helps to change the raw data to final, actionable data to geologists and drilling engineers.

4. Analysis and Interpretation

To guide drilling and evaluate formation characteristics, the data is thoroughly reviewed. Geologists assess readings on gamma rays, resistivity, and porosity to identify hydrocarbon-bearing zones and ascertain water saturation. Measurements from the acoustic and sonic tests, which evaluate the presence of fractures and the strength of rocks, are essential baseline data for wellbore stability. These analyzed data, when combined with other drilling data such as pressure readings and directional surveys, enhance well planning, completion design, and reservoir management and sustain them.

5. Integration with Advanced Technologies

Digital well logging operates with newer technological advancements like digital twins, AI, and machine learning. Data from the well is uploaded to the wellbore virtual model, enabling operators to predict and optimize with different drilling scenarios formation behavior, and operational parameters. AI helps with drilling strategy efficiencies with adjustments by finding patterns, suggesting anomalies.

How Simulation Technologies are Used for Digital Well Logging in Oil Drilling

Operators can predict well behavior, optimize drilling strategies and improve their decision-making capabilities by integrating real-time downhole data with advanced oil and gas simulation technologies.

Integration of Simulation with Digital Well Logging

Digital well logging offers high-resolution measurements of resistivity, porosity, acoustic parameters, gamma-ray, pressure, and temperature, which enhances the incorporation of simulation technologies with digital well logging. These, along with the surrounding formations, are processed in integrated simulation software which resolves the downhole parameters of the borehole. The combination of physical data and mathematical replicas of the borehole conditions allows the visualization of the borehole environment, assessing potential characteristics of the reservoir and planning for challenges before their occurrence.

Predictive Drilling and Formation Analysis

Within digital well logging, one of the first and probably the most successful use cases of simulation is in predictive drilling. Real-time logging data is used to build formation models, which in turn get simulated to assess the potential rock response to drilling, the probable drilling targets, the positions of hydrocarbons, and formation pressure instability. Minimizing unproductive drilling and optimizing well paths, while knowing mechanical limitations, can use this capability of prediction.

Enhanced Reservoir Characterization

Digital well logging becomes enriched with advanced interpretation methodologies that rely on simulation technologies. Advanced models that can simulate variations of fluid and pressure in addition to porosity and rock behavior in the reservoir go a long way. By coupling digital well logs with these models, geo-scientists can better evaluate the distribution of hydrocarbons, reservoir interconnections, and the volume of hydrocarbons that can be recovered.

Digital Twins in Well Logging

Integrating digital twins in simulation technologies represents a cutting edge technological advancement. A digital twin allows real-time updates to operate on a virtual digital wellbore replica from digital well log data. This capability allows operators to asses various drilling scenarios and predict behaviors from shifting parameters and borders. Adopting digital twins in workflow enables anticipatory decision-making to formation damage and operational risk. Digital twins also aid in fine-tuning production strategies.

Optimizing Drilling Efficiency and Safety

Simulation technologies impact operational risk and enhance safety to a certain degree. The drill bit, drilling mud, and formation models enable operators to drill under the most optimal parameters and avoid certain zones to decrease equipment erosion wear. Additionally, potential problems such as high-pressure compartments and fractures can be identified long before mitigation measures are put in place, thanks to simulations.

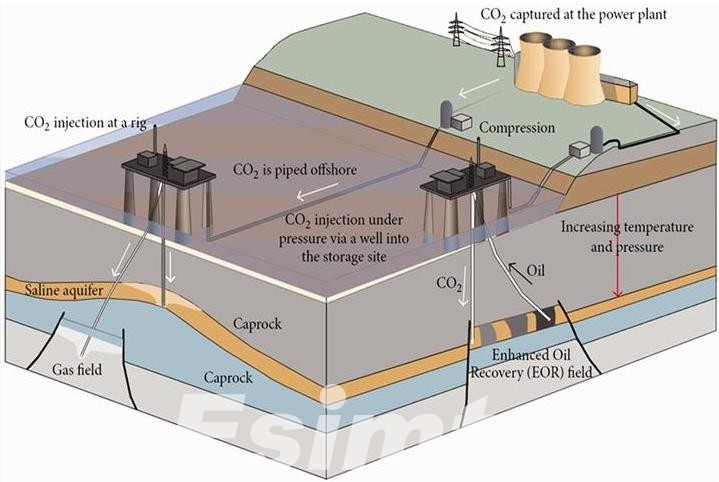

Supporting Enhanced Oil Recovery (EOR)

Once the well head is erected the most important to drilling simulation, projected from the digital well log is fluid dynamics. Logging data enables control over the predicted pressure wells in the reservoir and to optimize the injection for maximal hydrocarbon recovery. This maintains reservoir sustainability and efficiency for the lifetime of the well.

Applications of Digital Well Logging in Oil Drilling

This chart highlights the versatility of digital well logging and its critical role at every stage of oil and gas operations.

| Application Stage | Purpose / How Digital Well Logging is Used |

| Exploration | Identifies hydrocarbon-bearing formations, evaluates reservoir quality, and determines drilling feasibility. |

| Appraisal Wells | Confirms reservoir extent, thickness, fluid content, and overall potential for production. |

| Development Wells | Guides well placement, trajectory planning, and completion strategies to maximize hydrocarbon recovery. |

| Production Monitoring | Tracks changes in reservoir pressure, fluid movement, and formation behavior to optimize production and recovery. |

| Enhanced Oil Recovery (EOR) | Monitors injection and production zones, evaluates fluid saturation, and supports optimization of EOR techniques. |

| Geomechanical Analysis | Assesses rock stability, detects fractures, and ensures wellbore integrity during drilling and production. |

Final Thoughts

Digital well logging facilitates the collection of accurate, timely, actionable with remarkable advancements in real time subsurface data processing. It has become a sance in the oil drilling industry, enhancing decision quality, sustainability, safety, and cost in operations.