How to Monitor Well Integrity Effectively

The safe and efficient operations of the oil and gas industries hinge on well integrity. The wells’ structural soundness affects operational efficiency, environmental protection, and compliance with regulations. With production intensifying, wells aging, and regulations changing, the need to monitor well integrity is growing. This paper discusses the significance, monitoring technologies, and best practices regarding well integrity.

Understanding Well Integrity

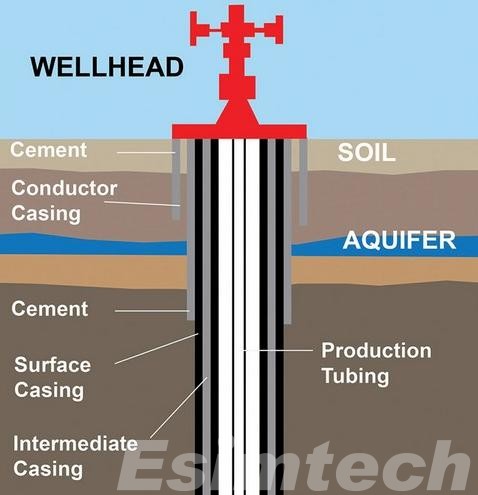

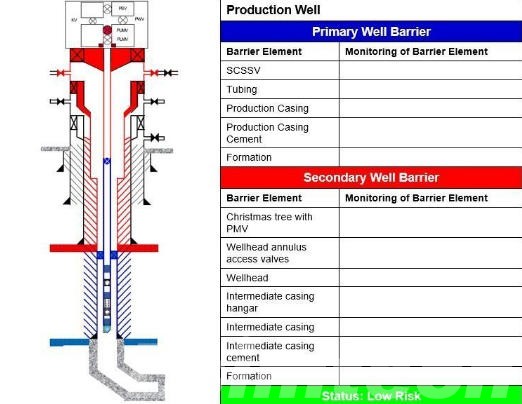

Well integrity is the ability of a well to contain and control subsurface fluids throughout the entire life cycle of the well. A well achieves “integrity compliance” when it safely conveys hydrocarbons from the reservoir to the surface, isolates other formations, and prevents leaks into or from the produced formation.

Key aspects

- Structural Integrity: The casing, tubing and wellhead hardware’s strength and stability.

- Barrier Integrity: The cement, packers, and other sealing systems’ ability to provide and maintain seals.

- Pressure Containment: The capacity to resist and contain internal and external pressure without leakage or permanent deformation.

The failure to maintain any of these aspects results in environmental contamination, costly downtime, and a well blowout.

Why Monitoring Well Integrity is Important

Protecting Safety and the Environment

The primary reason for monitoring well integrity is safety. Poorly maintained wells increase the risk of danger to both personnel and the public. Well leaks and structural failures result in uncontrolled discharges of hazardous fluids and hydrocarbons, which can trigger explosions and fires, in addition to polluting the environment. Regular monitoring makes it possible for operators to recognize potential failures in the well system containment and to prevent accidents, and the operational incidents that will have to be managed.

Protecting the environment is also a critical concern. Since oil and gas wells pass through sensitive ecosystems, any leakage can have severe and unprecedented consequences for groundwater, soil, and other supportive ecosystems. Monitoring well integrity can assure the operational containment systems and the ecosystem protective systems unintentionally maintained monitoring will system leakage for safe containment, and monitoring will containment to minimize leakage.

Ensuring Operational Efficiency

From a business perspective, monitoring well integrity also directly affects operational efficiency. A well that is properly maintained will produce more reliably and will mean fewer emergency interventions will be required. Operational management of leaks, corrosion, and other well maintenance issues will be more efficient and effective the more the operational management is overtly planned. In this sense, monitoring well integrity is more positively proactive. More positively proactive monitoring will be a more effective operational management strategy.

Meeting Regulatory Requirements

Around the world, compliance with the regulatory frameworks includes the mandatory monitoring of well integrity. As well operational monitoring reduces the chances of fines, abandonment, and legal uncertainties, the operators are motivated to demonstrate continuous assessment of the well. In addition, well monitoring fosters the trust of stakeholders and regulators in the operator’s corporate responsibility, as well as in the operational and documented compliance of the company.

Key Technologies for Monitoring Well Integrity

Pressing advancements in technology make it feasible for operators to implement continuous well monitoring systems and utilize these systems for proactive failure avoidance.

1. Downhole Pressure and Temperature Sensors

Installing downhole pressure and temperature sensors enables the technology to provide real time, continuous downhole condition monitoring. Pressure anomalies including unexpected pressure absence, leaks, and extreme differential pressure situations can be detected and monitored. Temperature irregularities and extreme differentials are also monitored and can detect fluid behaviors including gas and liquid phase transitions. Leak detection casing failures and other integrity complicating issues can be identified. Monitoring systems and advanced continuous system technologies help operators act on deteriorating situations before they spiral out of control.

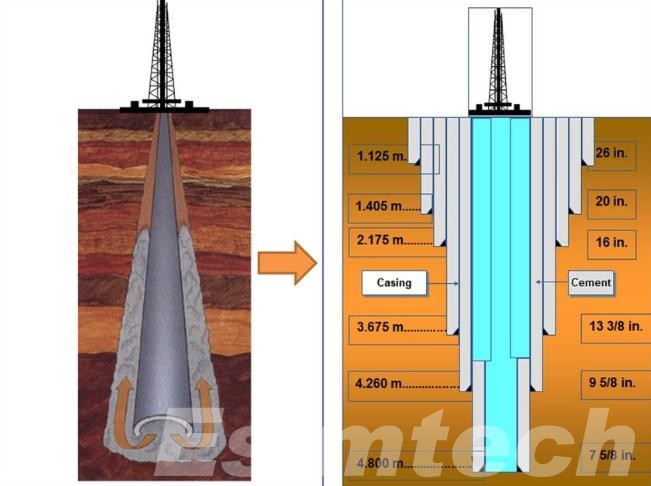

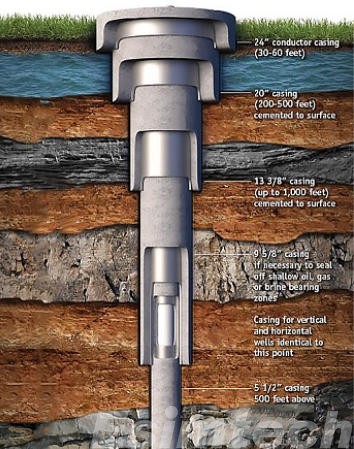

2. Casing Inspection Technologies

Casing is the well primary structure and integrity. Casing is also the primary well structural element. In addition to casing structural integrity assessment there are ultrasonic systems, magnetic flux leakage sensors, and caliper logging systems and other inspection systems to identify corrosion, deformation, and casing linings wear, cracks, and other weak points.

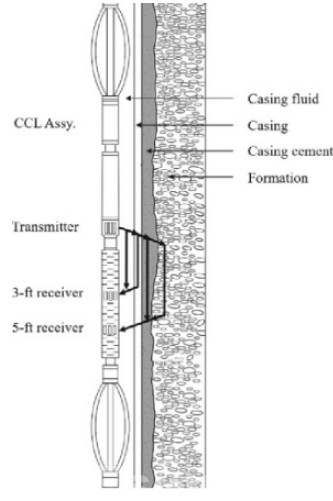

3. Cement Bond Logging (CBL)

Cement is particularly important for well construction because it isolates and prevents fluids from migrating between formations. Cement bond logging assesses the quality and consistency of cement along the casing and logs any deficits. Recognizing poor cement coverage and inadequate bonding is critical to leak-proofing and preserving the integrity of a well’s barriers.

4. Leak Detection Systems

Technologies such as fiber optic monitoring, distributed temperature sensing, and passive acoustic sensors help detect fluid migration from the wellbore. Leak detection systems identify potentially hazardous, concealed leaks so that operators can take action to prevent operational hold-ups or environmental damage.

5. Simulation Technologies

Oil and gas simulation technologies model the various aspects of a well, thus allowing engineers to study the structure and the mechanics of fluid and other dynamics without any wellbore intervention. This allows operators to identify and address failures and to optimize their upkeep plans.

Here’s a chart summarizing how simulation technologies are used for monitoring well integrity

| Aspect | Description | Benefits |

| Digital Twins | Virtual replicas of physical wells updated with real-time sensor data | Detect anomalies early; predict breaches before critical failure; enable proactive maintenance |

| Predictive Modeling | Simulation of well behavior under varying operational conditions | Assess risk of casing failure, cement degradation, or fluid migration; plan targeted preventive measures |

| Stress and Structural Analysis | Modeling mechanical loads and environmental stresses on casing, tubing, and cement | Identify weak points and areas prone to deformation, corrosion, or fatigue; guide reinforcement strategies |

| Integration with AI and Data Analytics | Combining historical and real-time well data with AI algorithms for simulation | Improve accuracy of predictions; enable proactive monitoring; optimize operational decisions |

| Operational Planning and Optimization | Using outputs of drilling and well control simulations to plan maintenance, interventions, and production adjustments | Reduce downtime, extend well lifespan, enhance safety and efficiency |

| Regulatory Compliance Support | Simulated scenarios and monitoring data provide evidence for regulators | Demonstrates proactive well integrity management; ensures environmental and safety compliance |

6. Artificial Intelligence and Predictive Analytics

Artificial intelligence (AI) and machine learning analyze large volumes of data obtained from sensors and other monitoring systems, and identify, predict, and provide insights on patterns and anomalies. Predictive analytics facilitated the implementation of proactive maintenance to regulate downtimes, operational hazards, and maintenance costs.

Best Practices for Monitoring Well Integrity

Implementing best practices enable operators to detect potential issues early, manage issues, and extend well operational life. Using best practices along with sophisticated technologies provide proactive measures for well integrity management through all stages of a well’s life cycle.

1. Establish a Baseline Assessment

Setting a comprehensive baseline assessment to address well integrity monitoring entails first evaluating the condition of casing, tubing, cement, and wellhead components. Baseline data serves a reference point of baseline inspections, capturing deviation of integrative components of a well that may signal developing issues. Thorough inital inspections of a well condition baseline data is crucial in ensuring that subsequent assessments of a well’s behavior for accurate changes is effective.

2. Implement Continuous Monitoring

For early anomaly detection, the continuous surveillance of wells’ downhole pressure, temperature, and fluid composition parameters are essential. Operators are able to identify and diagnose potential leaks and other integrity challenges through the detection of unusual patterns driven by real-time sensor data. Continuous monitoring coupled with automated alert systems streamlines the flagging of potential problems and minimizes operational risk and downtime.

3. Use Advanced Inspection Technologies

Well integrity requires constant examinations. Advanced Technologies like Ultrasonic Testing, Magnet Flux Leaking, Caliper Logging, and Cement Bond Logging offer clearer qualitative pictures of a well’s structural and barrier conditions. Well health assessments benefit from the application of multiple techniques, as the estimation of detection failure increases.

4. Leverage Simulation and Digital Twin Technologies

Operators use simulations to predict and analyze probable conditions a well will operate under. Digital twins are virtual copies of the physical wells and are designed to predict the stress and pressure a well could undergo as well as potential failure zones. The simulation of potential failure zones coupled with real-time sensors data provides operators with the ability to resolve maintenance and structural issues before failure and optimize maintenance.

5. Adopt Predictive Maintenance Strategies

Predictive maintenance eliminates potential issues before they occur, making maintenance more efficient as it will reduce costs and time associated with unscheduled downtimes. Predictive analytics allow operators to monitor and analyze historical and real-time data for potential integrity issues, hence making potential integrity issues solvable.

6. Maintain Detailed Records and Compliance Documentation

Keeping detailed and poroper spaced and documented records is evidence of good practice that improves operational processes and efficiency. Transparent accounts of inspections, sensor data, and maintenance activities enable accountability. Records that are sufficiently documented allow for longitudinal trend analysis and facilitate well integrity management decisions by operators.

7. Foster a Culture of Safety and Training

Having a culture of safety is foundational to ensure the effective well integrity monitoring. It is, however, the well trained personnel that makes a difference. Training staff on the appropriate use of technology, best operational practices, and emergency procedures ensures effective system use, system issue mitigation, and quick issue resolution in the monitoring process. Safety culture improves human error critical and well integrity maintenance.

Challenges and Solutions in Monitoring Well Integrity

| Challenge | Description | Solution |

| Aging Wells | Older wells may have incomplete records and outdated infrastructure, making condition assessment difficult. | Conduct thorough baseline inspections and deploy advanced monitoring tools to accurately evaluate well condition and reduce the risk of unexpected failures. |

| Harsh Downhole Conditions | Extreme pressure, temperature, and corrosive fluids can degrade sensors and monitoring equipment. | Use high-temperature, corrosion-resistant sensors to ensure reliable monitoring under extreme conditions and extend sensor lifespan. |

| Data Management | Large volumes of monitoring data can be overwhelming and difficult to analyze effectively. | Implement centralized data platforms with AI-driven analytics to process data efficiently, enabling faster anomaly detection and informed decision-making. |

| Detection of Subtle Leaks | Slow or minor leaks may go undetected until significant damage occurs. | Deploy acoustic sensors, fiber optic monitoring, and distributed temperature sensing to detect leaks early, preventing environmental and operational damage. |

| Cost Constraints | Comprehensive monitoring programs can be expensive, limiting coverage or frequency of inspections. | Prioritize high-risk wells and adopt predictive maintenance strategies to optimize monitoring costs while reducing emergency repair expenses. |

| Complex Well Designs | Multilateral, high-angle, and deep wells are challenging to monitor due to accessibility and geometry. | Utilize digital twins and advanced simulation technologies to enable proactive monitoring and maintenance planning in hard-to-access areas. |

| Regulatory Compliance | Different regions have varying well integrity requirements, increasing operational complexity. | Maintain detailed monitoring records and integrate compliance reporting into monitoring systems to meet regulations and demonstrate responsible well management. |

Final Thoughts

Monitoring well integrity is pivotal in the oil and gas industry to ensure operations are environmentally conscious, socially responsible, and profitable. Operators are able to confirm that their wells are structurally sound, remain compliant and efficient, and safe throughout all operational phases, by embracing and best practices, digital technology, and monitoring best practices.